A flattening treatment method and treatment device for polyamic acid resin solution

A polyamic acid resin and processing device technology, which is applied in the direction of flat products, household utensils, and other household utensils, can solve problems such as no special treatment methods for polyamic acid resin solutions, and achieve simple structure, uniform dispersion and stability , easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Example of flattening treatment device for polyamic acid resin solution

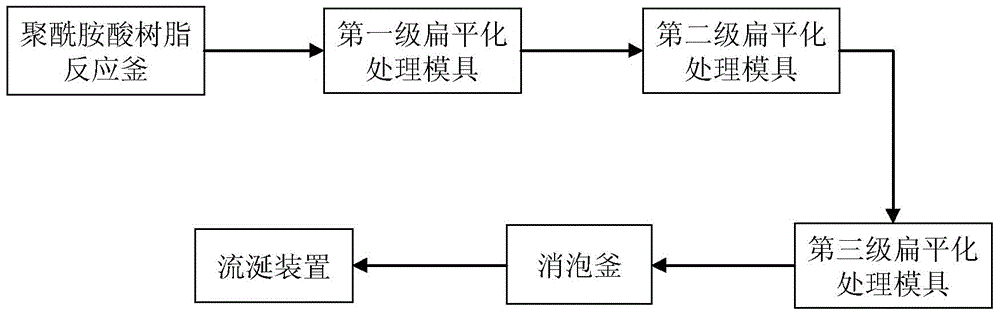

[0019] Embodiment of the flattening processing device of the polyamic acid resin solution figure 1 As shown, after the polyamic acid resin synthesis reaction kettle, the flattening molds from the first to third stages are sequentially connected, followed by the defoaming kettle, and then the salivation device.

[0020] The first-level to third-level flattening molds have slit openings, the length of the slit opening is 1200 mm, and the opening width is 0.6 mm.

[0021] The first-level and third-level flattening molds are equipped with cooling devices, and the mold temperature is -5°C. The second-level flattening molds are equipped with heating devices, and the mold temperature is 42°C.

[0022] In this example, the material conveying pipeline and the flattening mold are connected through a special adapter interface. The material conveying pipelines connected to the flattening mold are all straigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com