A plasma arc welding device and process for ultrasonic assisted perforation

A plasma arc and ultrasonic-assisted technology, applied in the direction of plasma welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of poor adaptability, inability to produce small holes, etc., and achieve stable welding process, improved stiffness, strengthened The effect of thermo-mechanical action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

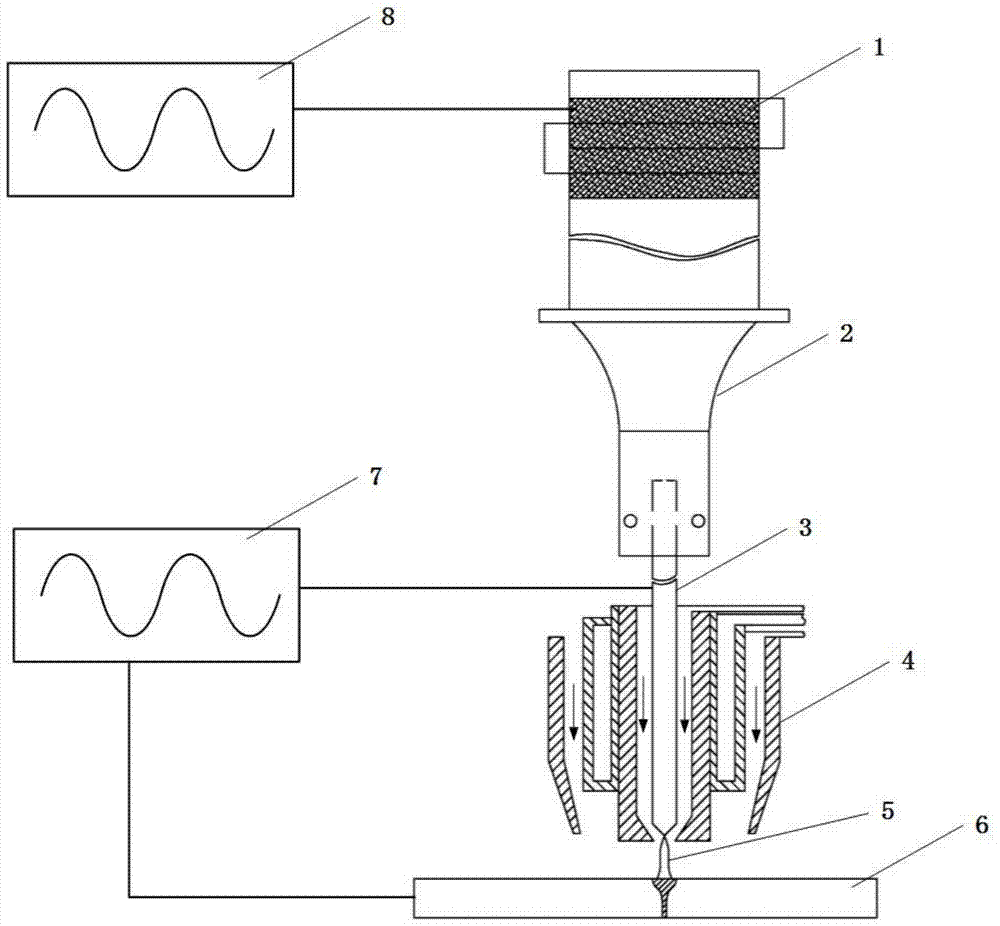

[0037] like figure 1 As shown, a plasma arc welding device for ultrasonic-assisted perforation includes an ultrasonic vibration and conduction unit, and the ultrasonic vibration and conduction unit includes an ultrasonic generator 8, an ultrasonic transducer 1 and a horn 2 connected in sequence, and the ultrasonic transducer The energy device 1 is tightly connected with one end of the horn 2 through a stud. The other end of the horn 2 is cut open and a hole is opened in the center to clamp the tungsten electrode 3, and at the same time, two hexagon socket bolts are used to fasten it so that the power ultrasonic vibration can be transmitted between the tungsten electrode 3 and the horn 2. And a material with insulation, heat insulation, and power ultrasonic vibration is applied between the two to realize the effective separation of the ultrasonic circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com