Method for performing stainless steel strip-electrode submerged-arc build-up welding on low-alloy parent steel

A stainless steel strip and submerged arc surfacing technology, which is applied in arc welding equipment, welding media, welding equipment, etc., can solve problems such as cracking and peeling of the stainless steel surfacing layer, improve bonding strength, improve comprehensive performance, and realize safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

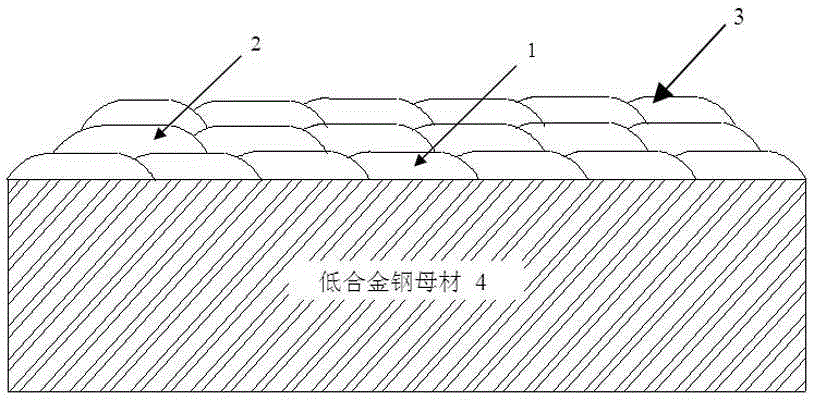

[0062] In this embodiment, the low-alloy steel base material is SA508Gr3Cl2 low-alloy steel, and the size of the test plate is δ100×350×550mm; the specific welding process is:

[0063] Visual inspection and dimensional inspection of the surface to be welded of SA508Gr3Cl2 low alloy steel, and MT inspection.

[0064] Use EQ309L stainless steel welding strip, RECORDINT101Q5 flux on the SA508Gr3Cl2 low-alloy steel base material surface to be surfacing, adopt the horizontal position belt submerged arc surfacing method to carry out the first layer of stainless steel belt submerged arc surfacing welding, and form the first layer of stainless steel surfacing solder layer. During this process, the strip size of the EQ309L stainless steel welding strip is 60mm×0.5mm; the welding current is 750A; the welding voltage is 25V; the preheating temperature is 130°C; the welding speed is 180mm / min; the interlayer temperature is 140°C. And the overlapping amount between each weld bead formed i...

Embodiment 2

[0071] In this embodiment, the low-alloy steel base material is SA508Gr3Cl2 low-alloy steel, and the size of the test plate is δ100×350×550mm; the specific welding process is:

[0072] Visual inspection and dimensional inspection of the surface to be welded of SA508Gr3Cl2 low alloy steel, and MT inspection.

[0073] Use EQ309L stainless steel welding strip, RECORDINT101Q5 flux on the SA508Gr3Cl2 low-alloy steel base material surface to be surfacing, adopt the horizontal position belt submerged arc surfacing method to carry out the first layer of stainless steel belt submerged arc surfacing welding, and form the first layer of stainless steel surfacing solder layer. In this process, the strip size of the EQ309L stainless steel welding strip is 60mm×0.5mm; the welding current is 770A; the welding voltage is 25V; the preheating temperature is 121°C; the welding speed is 180mm / min; the interlayer temperature is 125°C. And the overlapping amount between each weld bead formed is 5~...

Embodiment 3

[0080] In this embodiment, the low-alloy steel base material is SA508Gr3Cl2 low-alloy steel, and the size of the test plate is δ100×350×550mm; the specific welding process is:

[0081] Visual inspection and dimensional inspection of the surface to be welded of SA508Gr3Cl2 low alloy steel, and MT inspection.

[0082] Use EQ309L stainless steel welding strip, RECORDINT101Q5 flux on the SA508Gr3Cl2 low-alloy steel base material surface to be surfacing, adopt the horizontal position belt submerged arc surfacing method to carry out the first layer of stainless steel belt submerged arc surfacing welding, and form the first layer of stainless steel surfacing solder layer. In this process, the strip size of the EQ309L stainless steel welding strip is 60mm×0.5mm; the welding current is 760A; the welding voltage is 28V; the preheating temperature is 150°C; the welding speed is 170mm / min; the interlayer temperature is 200°C. And the overlapping amount between each weld bead formed is 5~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com