Preparation method and application of carbonyl cobalt catalyst

A technology of cobalt carbonyl catalyst and application method, which is applied in the direction of carbon monoxide or formate reaction preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems such as the preparation method of cobalt carbonyl catalyst that are not clearly stated, and achieve selectivity And the effect of high yield, good activity and selectivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

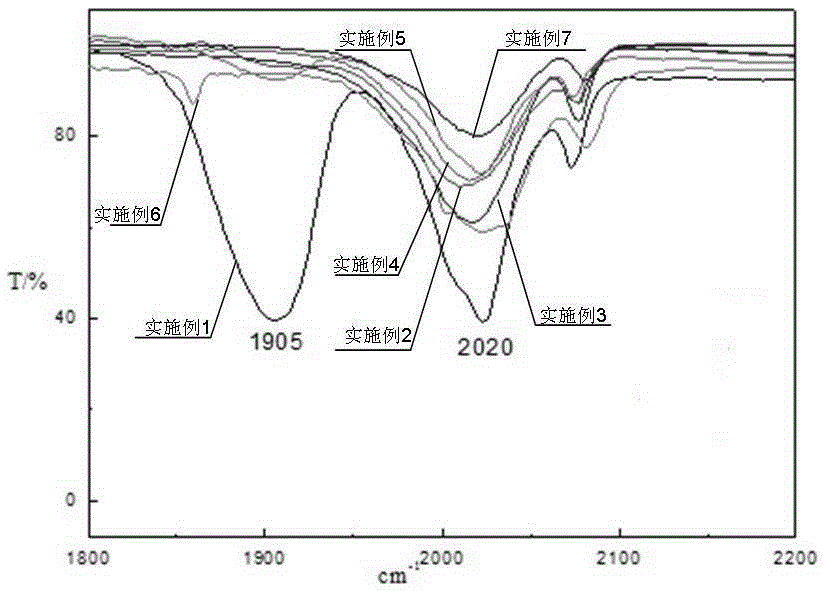

Image

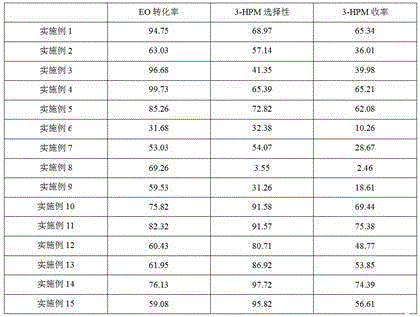

Examples

Embodiment 1

[0030] Dissolve 0.7472g of cobalt acetate in 60mL of methanol, then add 1.5671g of hydrosulfite and 0.5304g of cobalt powder to prepare a solution, add the solution to the autoclave, and seal the autoclave; 2 Replace the air in the autoclave with gas for 3 times, then replace the gas in the autoclave with CO gas for 3 times, fill the autoclave with CO gas to make the CO gas pressure in the autoclave 2MPa; heat the autoclave to make it Raise the temperature to 50°C, and react for 3 hours at a stirring speed of 200r / min; after the reaction is completed, cool down and centrifuge to obtain an alcoholic solution of cobalt carbonyl catalyst; take 20.8g of the solution and place it in a high-pressure reactor , add 0.8559g3-hydroxypyridine, 6.6075g ethylene oxide, 7.21g methanol, seal the autoclave, first use N 2 The air in the autoclave was replaced with gas for 3 times, and the gas in the autoclave was replaced with CO for 3 times. CO gas was filled into the high-pressure reactor to...

Embodiment 2

[0032] Dissolve 0.7472g of cobalt acetate in 60mL of methanol, then add 2.0894g of hydrosulfite and 0.3536g of cobalt powder to make a solution, add the solution to the autoclave, and seal the autoclave; first replace the autoclave with argon Air 4 times, then replace the gas in the autoclave with CO gas 4 times, fill the autoclave with CO gas, make the pressure of CO gas in the autoclave 3MPa; heat the autoclave to 60°C, and stir At a speed of 200r / min, react for 4 hours; after the reaction is completed, cool down and centrifuge to obtain an alcohol solution of cobalt carbonyl catalyst; take 20.8g of the solution, place it in a high-pressure reactor, and add 0.8559g of 3-hydroxypyridine , 6.6075g ethylene oxide, 7.21g methanol, seal the autoclave, first replace the air in the autoclave with argon 4 times, then replace the gas in the autoclave 4 times with CO, and fill the autoclave with CO gas to make the CO gas The pressure is 7.5MPa, the temperature of the reaction kettle i...

Embodiment 3

[0034] Dissolve 0.7472g of cobalt acetate in 60mL of methanol, then add 1.5671g of hydrosulfite and 0.5304g of cobalt powder to prepare a solution, add the solution to the autoclave, and seal the autoclave; 2 Replace the air in the autoclave with CO gas for 5 times, then replace the gas in the autoclave with CO gas for 5 times, and fill the autoclave with CO gas to make the CO gas pressure in the autoclave 4MPa; heat the autoclave to make it Raise the temperature to 60°C, and react for 5 hours at a stirring speed of 200r / min; after the reaction is completed, cool down and centrifuge to obtain an alcohol solution of cobalt carbonyl catalyst; take 20.8g of the solution and place it in a high-pressure reactor , add 0.8559g3-hydroxypyridine, 6.6075g ethylene oxide, 7.21g methanol, seal the autoclave, first use N 2 Replace the air in the autoclave with gas 6 times, then replace the gas in the autoclave with CO 6 times, fill the high-pressure reactor with CO gas to make the CO gas p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com