High Thermal Conductivity SMD Bypass Diodes

A bypass diode, high thermal conductivity technology, applied in the field of diodes, can solve the problems of increasing the volume and cost of the junction box, large forward voltage drop of the bypass diode, and poor heat dissipation effect of the junction box, so as to improve the heat dissipation effect and reduce the volume. , the effect of good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

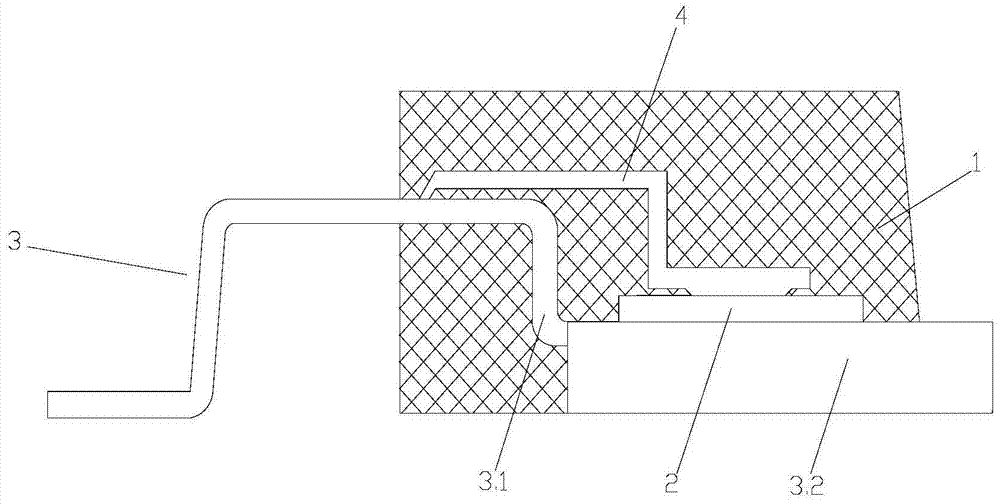

[0027] refer to figure 1 The high thermal conductivity chip bypass diode shown includes a body 1, a chip 2 made of deep-channel silicon technology, and a copper frame patch 3. The chip 2 and the frame patch 3 are molded in a half-package package structure In the body 1 of high thermal conductivity and low stress vinyl, the frame patch 3 is a stepped integrated structure composed of a thin piece 3.1 and a thick piece 3.2. The side of the thin piece 3.1 is higher than the side of the thick piece 3.2, and the connection between the thin piece 3.1 and the thick piece 3.2 Extend vertically upwards and then horizontally, and extend to the outside of the left side of the body 1. One end of the core particle 2 is soldered to the upper surface of the thick sheet 3.2 close to the step structure by soldering technology. Soldering can effectively control the welding porosity To i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com