Hydrochloric acid-assisted method for preparing organic and inorganic hybrid perovskite material

A perovskite material and organic technology, applied in the field of preparing high-quality perovskite thin films by one-step spin coating or continuous deposition, can solve the problems of yellowish color, poor crystallinity and low coverage of perovskite films, Achieve the effect of smooth surface, good crystallinity and high coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment relates to a kind of method that concentrated hydrochloric acid, lead iodide and methylamine iodide are dissolved in DMF and spin-coats perovskite film, and described method comprises the following steps:

[0043] 1) Dissolving 0.461g of lead iodide and 0.159g of methylamine iodide in 1mL of DMF to obtain a perovskite precursor solution;

[0044] 2) Take 80 uL of concentrated hydrochloric acid (the volume fraction of concentrated hydrochloric acid added is 8%) and add it to the perovskite precursor solution obtained in step 1 to form solution A.

[0045] 3) The solution A obtained in step 2) was spin-coated on the FTO substrate at 8000 rpm for 20 s and dried at room temperature to obtain a perovskite film.

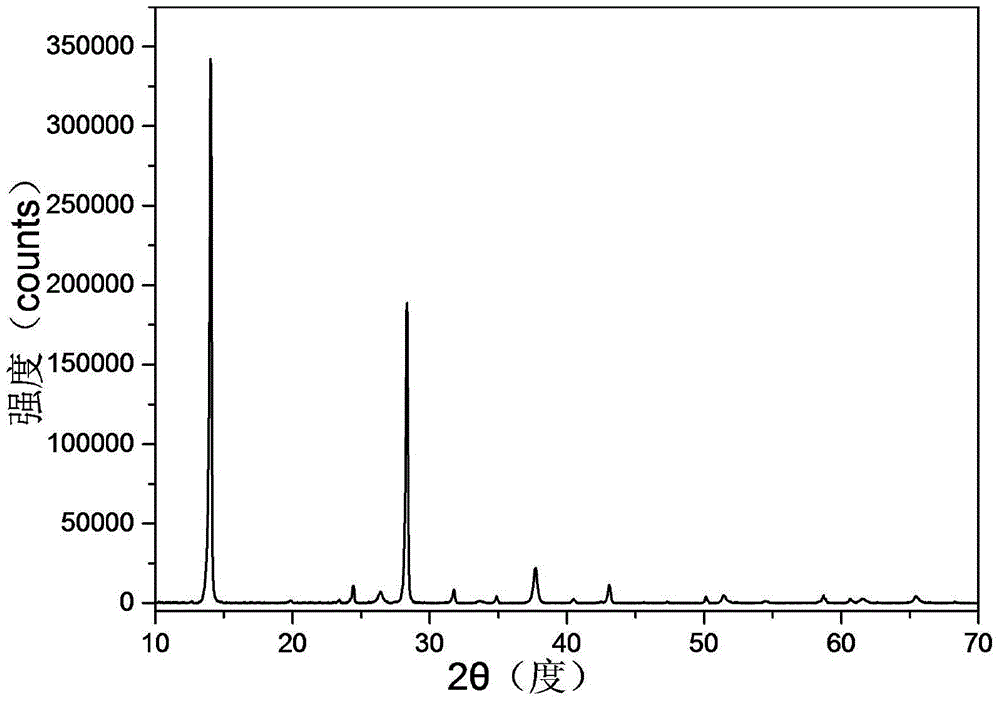

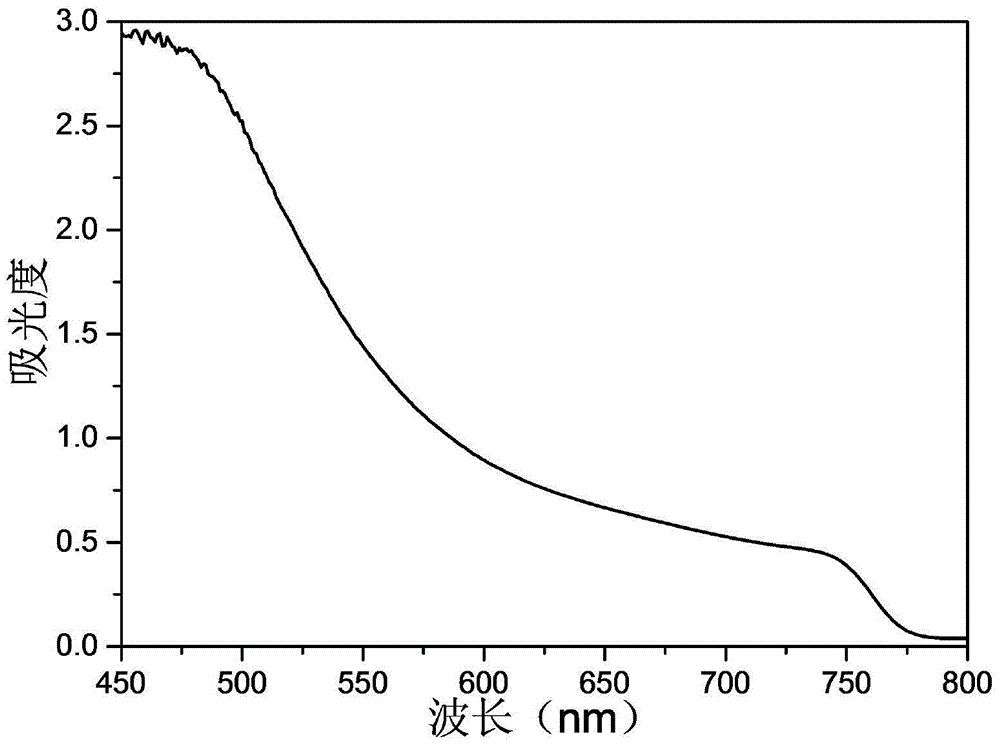

[0046] figure 1 It is the X-ray diffraction spectrum of Example 1, from which it can be concluded that the crystal form of the perovskite film obtained in Example 1 is perovskite, and the crystallinity is good; figure 2 It is the ultraviolet-visib...

Embodiment 2

[0050]This embodiment relates to a kind of method that concentrated hydrochloric acid, lead iodide and methylamine iodide are dissolved in DMF and spin-coats perovskite film, and described method comprises the following steps:

[0051] 1) Dissolve 0.461g of lead iodide and 0.159g of methylamine iodide in 1mL of DMF and ultrasonically obtain a perovskite precursor solution;

[0052] 2) Take 40 uL of concentrated hydrochloric acid (the volume fraction of concentrated hydrochloric acid is 4%) and add it dropwise into the perovskite precursor solution obtained in step 1 to form solution A.

[0053] 3) The solution obtained in step 2 was spin-coated onto the FTO substrate at 8000 rpm for 20 s and dried at room temperature to obtain a perovskite film.

[0054] Image 6 It is the X-ray diffraction spectrum of Example 2, from which it can be seen that the crystallinity of the perovskite obtained in Example 2 is better. Figure 7 It is the ultraviolet-visible spectrogram of Example 2...

Embodiment 3

[0056] This embodiment relates to a method in which concentrated hydrochloric acid and lead iodide are dissolved in DMF and a continuous deposition method is used to prepare a perovskite film. The method includes the following steps:

[0057] 1) 0.461g of lead iodide was dissolved in 1mL of DMF and ultrasonically dissolved to obtain a lead iodide solution;

[0058] 2) Take 96uL of concentrated hydrochloric acid (the volume fraction of concentrated hydrochloric acid added is 9.6%) and add dropwise into the lead iodide solution obtained in step 1 to form solution B.

[0059] 3) Spin-coat the solution B obtained in step 2 onto the FTO substrate at 4500 rpm for 20 s.

[0060] 4) Soak the spin-coated FTO substrate obtained in step 3 into a 10 mg / mL isopropanol solution of methylamine iodide MAI for 20 seconds, take it out, blow dry and anneal to obtain a perovskite film.

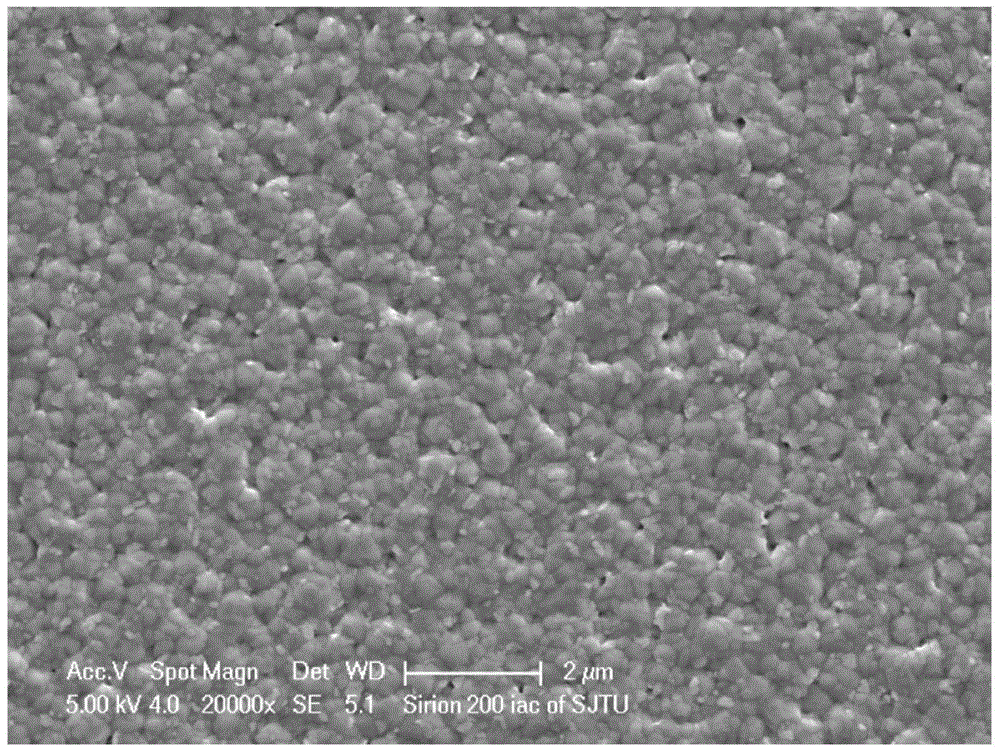

[0061] Figure 8 It is a scanning electron microscope photo of Example 3. It can be seen from the photo that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com