Preparation method of planar TEM sample

A sample and plane technology, applied in the field of preparation of TEM plane samples, can solve the problems of poor TEM imaging effect, inability to carry out analysis work, influence, etc., and achieve the effect of improving quality and success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] This embodiment uses FIB to prepare a planar TEM sample for observing dislocations in the active region and gate oxidation defects on a SRAM product.

[0044] The sample preparation steps of the main TEM samples are as follows:

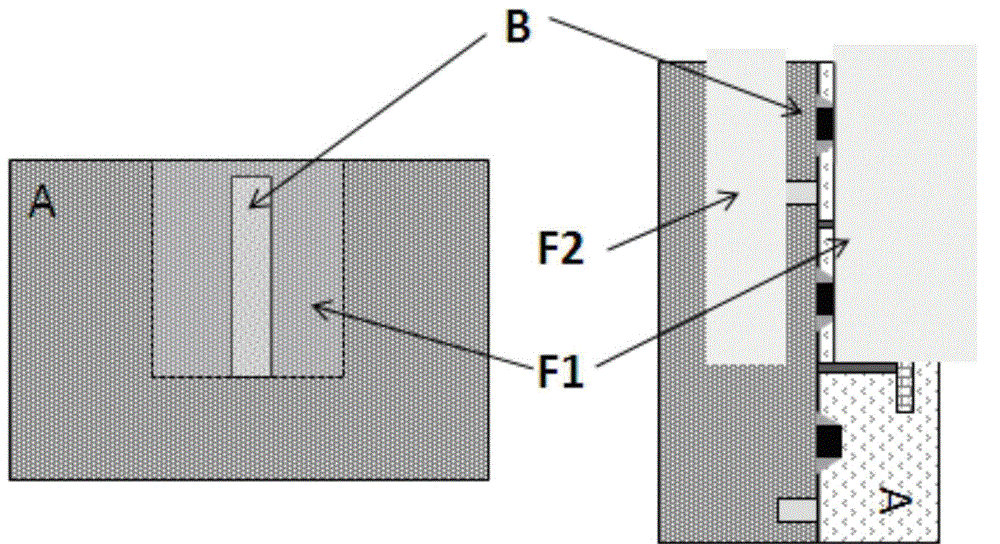

[0045] First, if Figure 2a As shown, observe the plane of the sample O in the FIB and look for the target region T. The section of the sample O is prepared by means of slices or masks, so that the section is constantly approaching the target T, and the final section is 1-10 microns away from the target. The target area includes the active region dislocation D1 and the gate oxide layer defect D2 that need to be observed in this analysis.

[0046] Next, rotate the sample and continue cutting on the plane of the sample by the ion beam of the FIB. At this time, a cutting plane parallel to the silicon substrate interface begins to form, starting from the top layer of the sample until the Poly layer is completely exposed, as shown in Fig. Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com