Method for achieving industrialization of multi-layer composite fullerene-like film on automotive engine

An automobile engine and fullerene-like technology, which is applied in coating, vacuum evaporation coating, metal material coating process, etc., can solve the problems of high deposition temperature, long deposition time, poor coating and binding force, etc. Achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

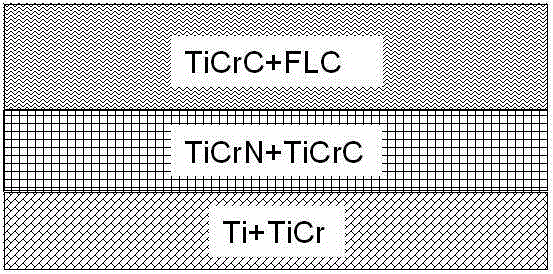

Method used

Image

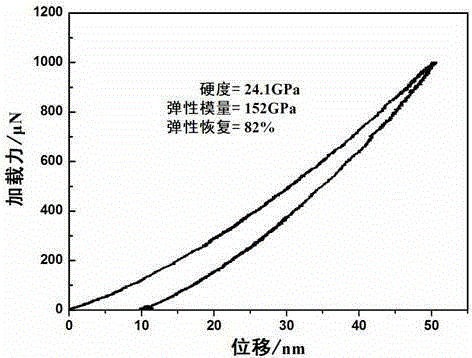

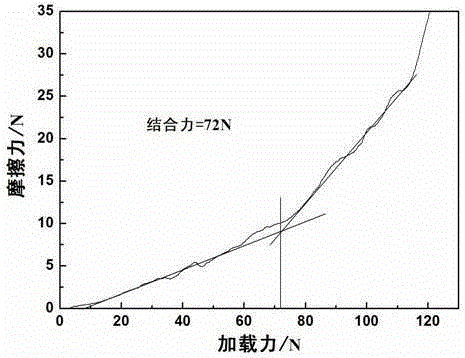

Examples

Embodiment 1

[0027] 1. The engine crankshaft (made of cast iron) to be deposited is cleaned in sequence by degreasing, rinsing, derusting, rinsing, dehydration, etc. in the cleaning device. The neutral water-based degreasing agent used in the cleaning device is used for degreasing, the deionized water overflow method is used for rinsing, the weak acid rust remover is used for rust removal, and absolute ethanol is used for dehydration. The entire cleaning process is carried out under ultrasonic vibration.

[0028] 2. Vacuuming First use a mechanical pump to pump the vacuum chamber to 800Pa, then turn on the Roots pump to pump the vacuum chamber to 10Pa, and finally turn on the molecular pump and low-temperature water vapor pump to pump the vacuum to 2.0×10 -3 Pa.

[0029] 3. Introduce 240sccm of Ar gas with a purity greater than 99.99%, and the air pressure is 0.40Pa; turn on the high-power pulse ion source power supply, and adjust the current of the high-power pulse ion source to 10A; turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com