Method for drying gastrodia elata at variable temperatures

A technology of variable temperature drying and Gastrodia elata, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of deformation and rehydration of Gastrodia elata, reduce the quality and decrease of Gastrodia elata, and achieve the purpose of improving the use efficiency and saving energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

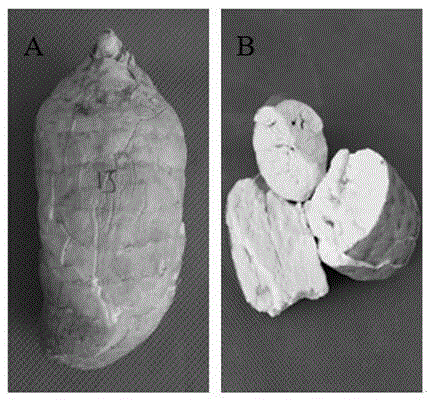

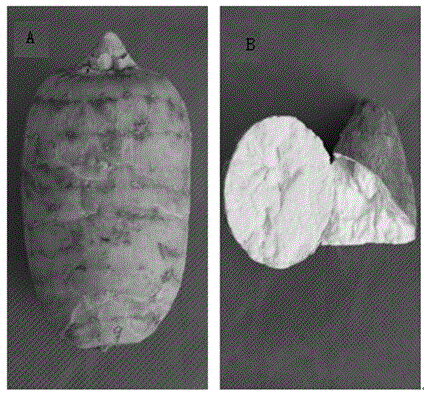

Image

Examples

Embodiment 1

[0017] Embodiment 1: the method of this Gastrodia elata variable temperature drying, concrete operation is as follows:

[0018] ①Steam the freshly washed Gastrodia elata at 95°C for 15 minutes, spread the gastrodia elata on a plate made of heat-conducting material, and cool at room temperature for 1 hour;

[0019] ② Put the cooled Gastrodia elata in a separate quick-freezing room, and freeze it at minus 30°C. The intermittent refrigeration method is used to monitor the internal temperature of Gastrodia elata through a high-sensitivity temperature sensor, so that the temperature of Gastrodia elata reaches minus 25°C. The entire quick-freezing process takes time for 5h;

[0020] ③Quickly transfer the quick-frozen Gastrodia elata to the vacuum drying chamber of the freeze dryer, seal it and then evacuate it to 30Pa, and perform intermittent heating. First set the temperature to 20°C, and adjust the set temperature to 30°C when the temperature of Gastrodia elata reaches minus 20°...

Embodiment 2

[0021] Embodiment 2: the method of this Gastrodia elata variable temperature drying, concrete operation is as follows:

[0022] ①Steam the freshly washed Gastrodia elata at 100°C for 10 minutes, spread the gastrodia elata on a plate made of heat-conducting material after steaming, and cool at room temperature for 2 hours;

[0023] ② Put the cooled Gastrodia elata in a separate quick-freezing room, and freeze it at minus 40°C. The intermittent refrigeration method is used to monitor the internal temperature of Gastrodia elata through a high-sensitivity temperature sensor, so that the temperature of Gastrodia elata reaches minus 30°C. The entire quick-freezing process takes time for 3h;

[0024] ③Quickly transfer the quick-frozen Gastrodia elata to the vacuum drying room of the freeze dryer, seal it and then vacuumize it to 50Pa, and perform intermittent heating. First, set the temperature to 25°C, and adjust the setting when the temperature of Gastrodia elata reaches minus 25°C...

Embodiment 3

[0025] Embodiment 3: the method of this Gastrodia elata variable temperature drying, concrete operations are as follows:

[0026] ①Steam the freshly washed Gastrodia elata at 105°C for 5 minutes, spread the gastrodia elata on a plate made of heat-conducting material, and cool at room temperature for 3 hours;

[0027] ② Put the cooled Gastrodia elata in a separate quick-freezing room, and perform quick-freezing under the condition of minus 45°C. The intermittent refrigeration method is used to monitor the internal temperature of Gastrodia elata through a high-sensitivity temperature sensor, so that the temperature of Gastrodia elata reaches minus 35°C. The entire quick-freezing process takes time for 4h;

[0028] ③Quickly transfer the quick-frozen Gastrodia elata to the vacuum drying chamber of the freeze dryer, seal it and then evacuate it to 90Pa, and perform intermittent heating. First, set the temperature to 23°C, and adjust the setting when the temperature of Gastrodia ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com