Non-contact temperature measurement device for induction cooker

A technology of non-contact temperature measurement and induction cooker, which is applied in measuring devices, optical radiation measurement, radiation pyrometry, etc., to improve accuracy and avoid time lag in temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

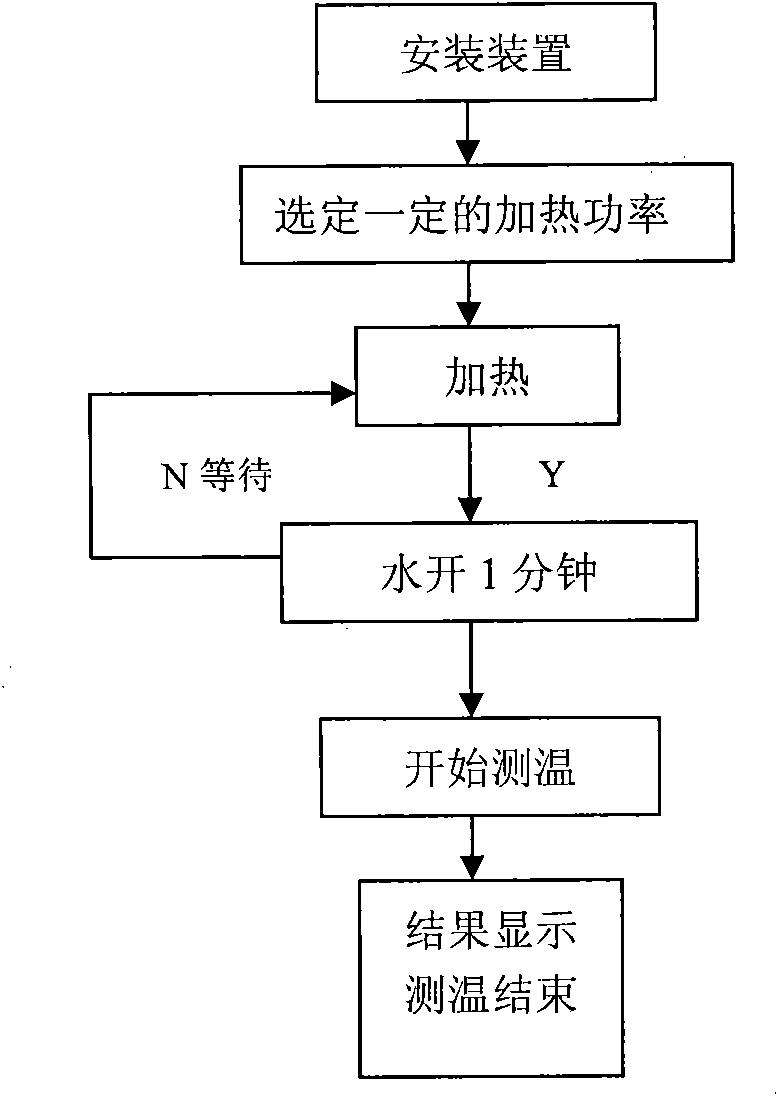

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the drawings:

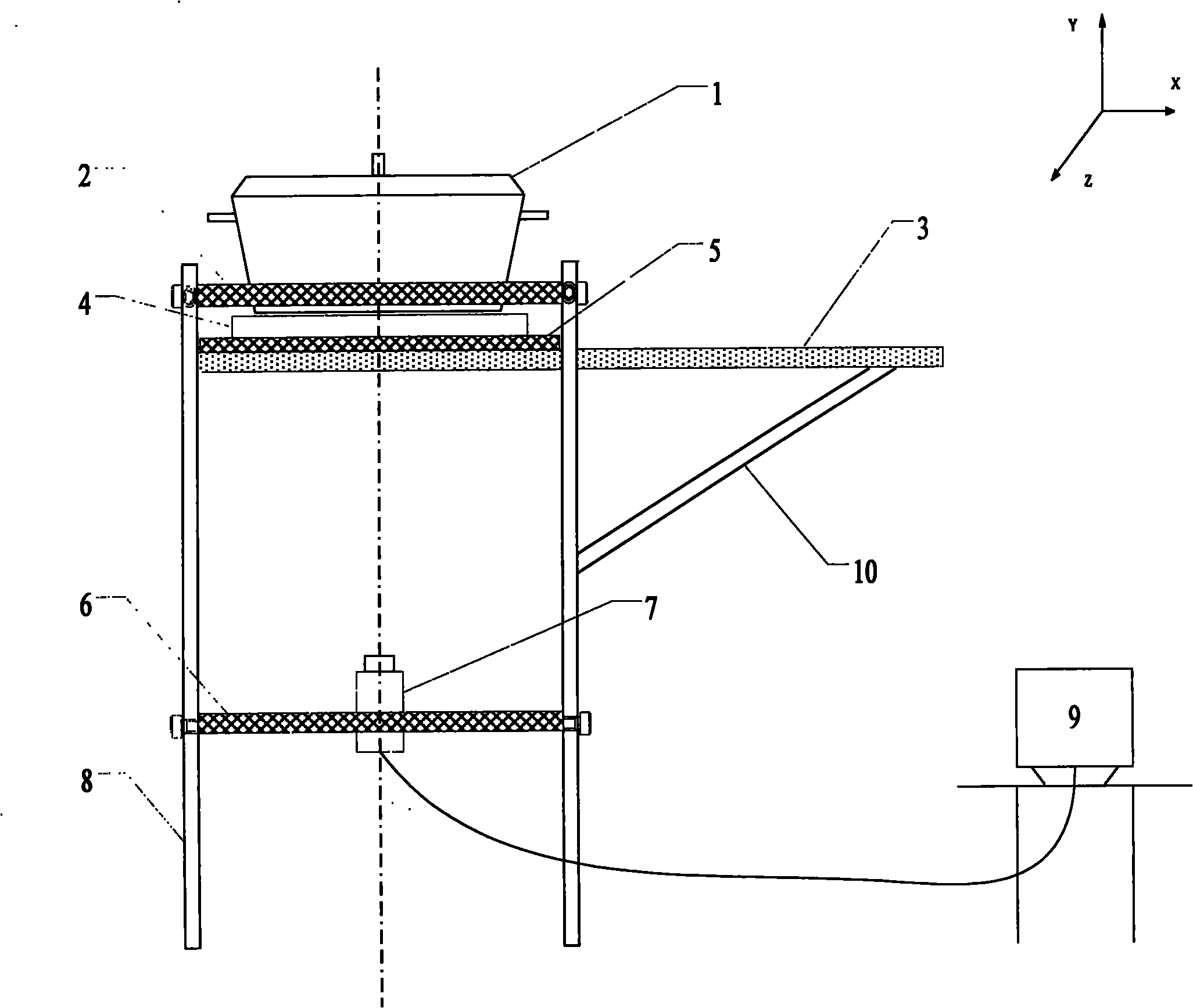

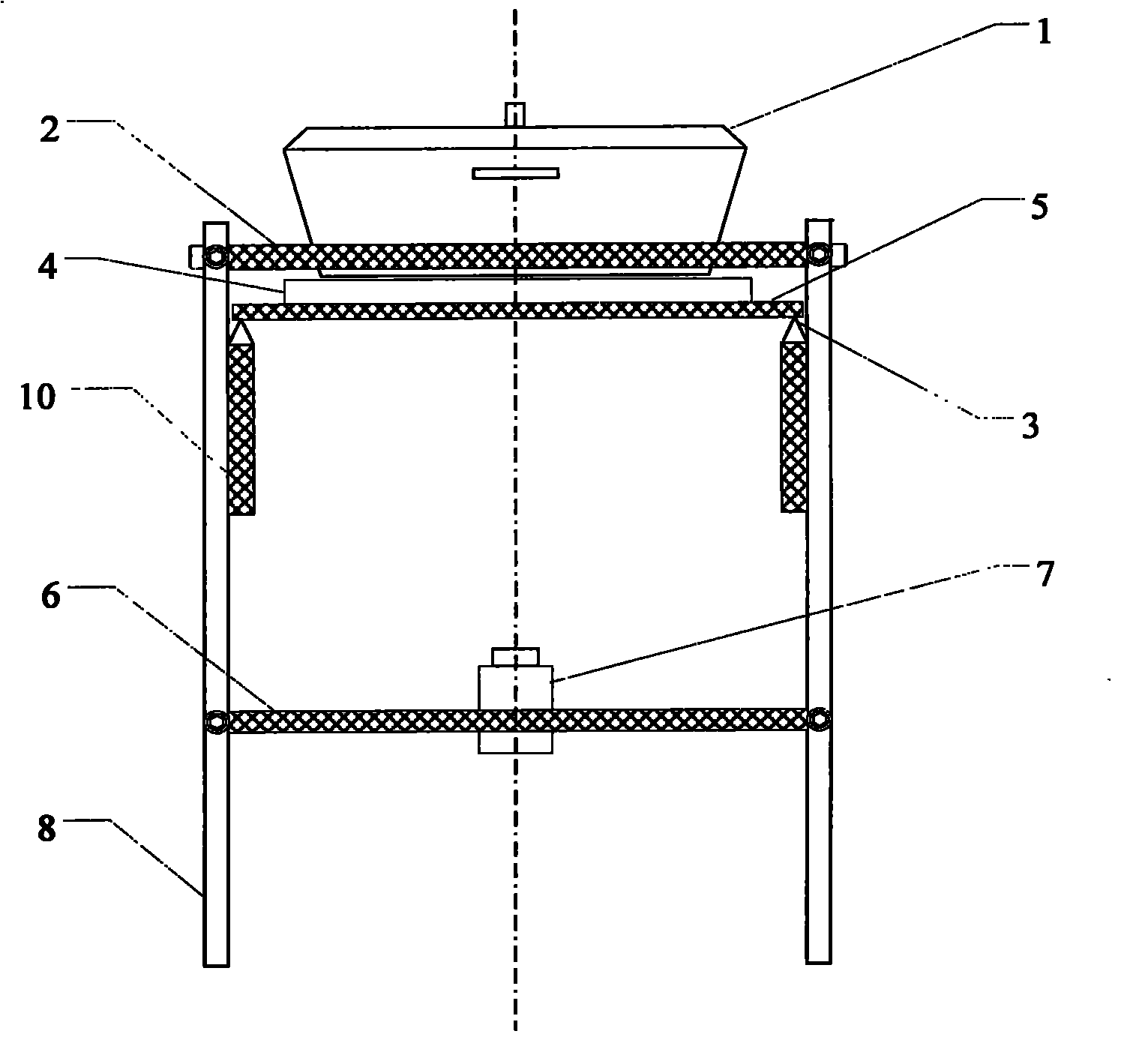

[0019] in figure 1 , figure 2 As shown, the present invention includes a thermal imager support panel 6 installed in the support 8 that can move up and down along the support 8. In the center of the thermal imager support panel 6 is installed an infrared thermal imager 7 with the lens facing upwards. The guide rails 3 are fixed on the sides, and the extension ends of the two guide rails 3 are supported by angle irons 10. The induction cooker support panel 5 is installed on the two guide rails 3, and the induction cooker support panel 5 with the induction cooker 4 can slide along the guide rail 3 in the X direction. The pot support panel 2 with a through hole in the middle is fixed on the bracket 8. The pot support panel 2 is located above the induction cooker 4, the pot 1 is placed in the through hole of the pot support panel 2, and the bottom center of the pot 1 is in the infrared The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com