CsPbX3 inorganic perovskite quantum dot light-emitting diode (LED) prepared through solution method

A quantum dot light-emitting and diode technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as poor stability and restrict development, and achieve the effects of low cost, mild conditions, and adjustable light-emitting wavelength range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The CsPbX prepared by the solution method described in this embodiment 3 The inorganic perovskite quantum dot light-emitting diode specifically comprises the following steps:

[0024] 1) Spin-coat PEDOT:PSS solution on the cleaned ITO glass at a rotation speed of 4000r / min, and heat at 140°C for 15min;

[0025] 2) Spin PVK solution at a speed of 4000r / min;

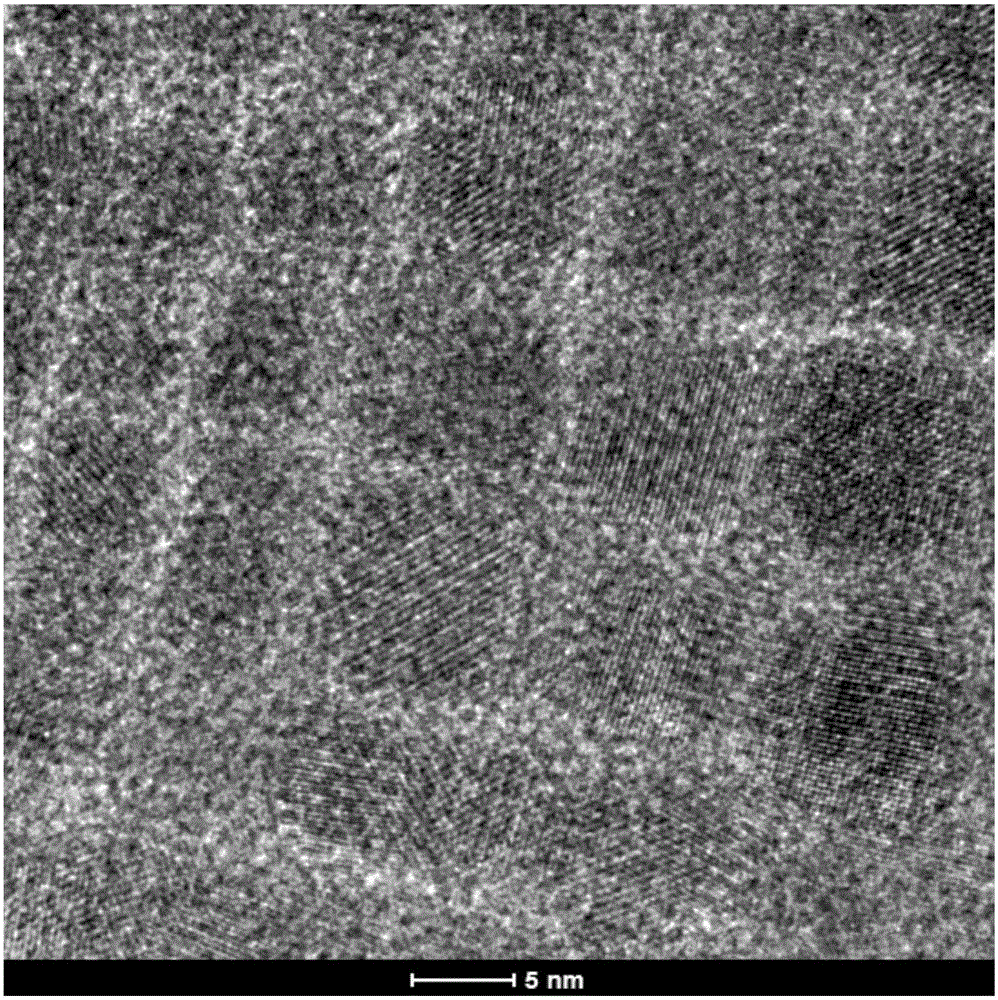

[0026] 3) Take an appropriate amount of CsPbBr 3 The quantum dot dispersion was spin-coated at a speed of 2000r / min, using CsPbBr 3 Quantum dot TEM transmission picture see figure 1 ;

[0027] 4) Deposit TPBi by thermal evaporation method, the deposition thickness is 40nm;

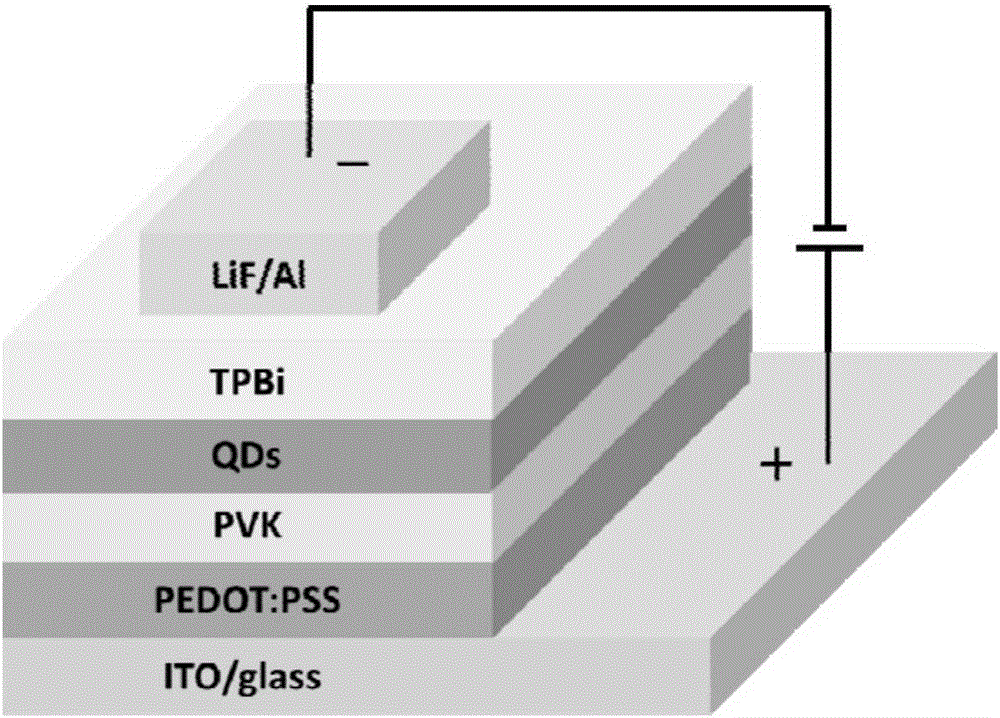

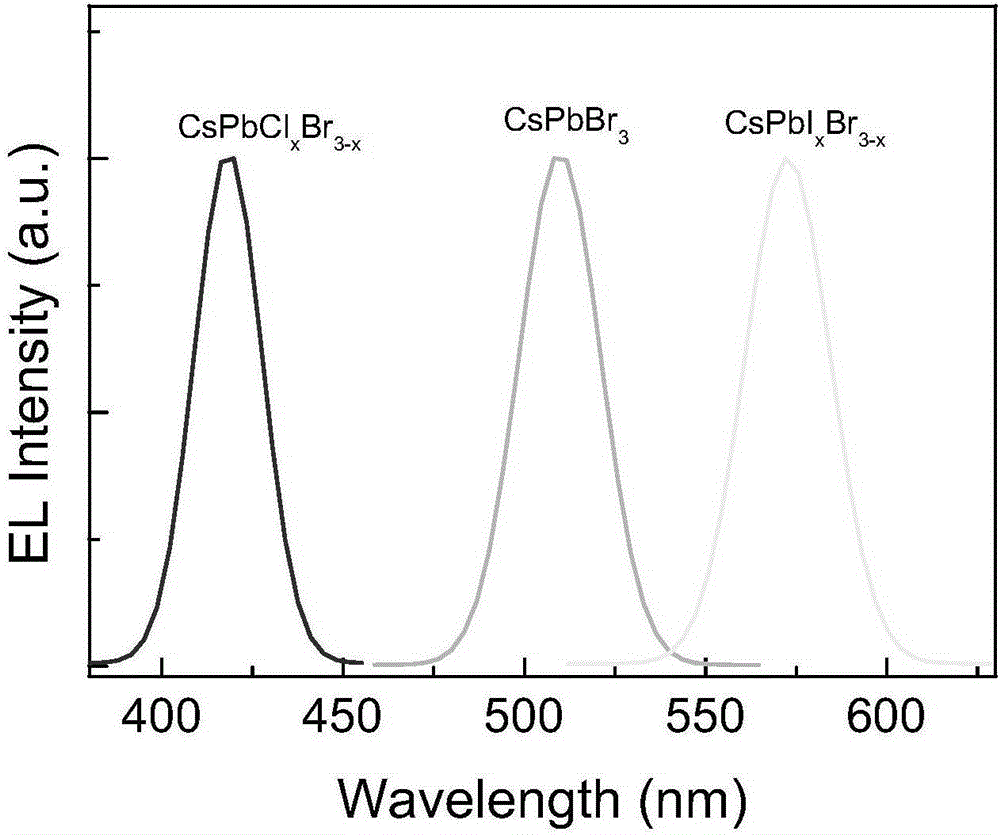

[0028] 5) Deposit LiF / Al electrodes with a mask plate by thermal evaporation method, and the thickness of LiF / Al electrodes is 1nm / 100nm to prepare CsPbX 3 Inorganic perovskite quantum dot light-emitting diode, the schematic diagram of its structure is shown in figure 2 , and its light-emitting diode emission spectrum is shown in image...

Embodiment 2

[0030] Similar to Example 1, the difference is that the PVK in step 2) of Example 1 is changed to poly-TPD, and other conditions are kept the same to obtain CsPbX 3 Inorganic perovskite quantum dot light-emitting diodes.

Embodiment 3

[0032] Similar to Example 1, the difference is that the PVK in step 2) of Example 1 is changed to TFB, and other conditions are kept the same to obtain CsPbX 3 Inorganic perovskite quantum dot light-emitting diodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com