A kind of colored polyester fiber preparation process

A technology for the preparation of colored polyester, which is applied in the direction of adding pigments to single-component polyester artificial filaments and spinning solutions, which can solve the problems of poor spinnability of polyester filaments, high cost of polyester filaments, and polyester filaments. Difficulty in dyeing, etc., to achieve better and brighter colors, higher color fastness, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

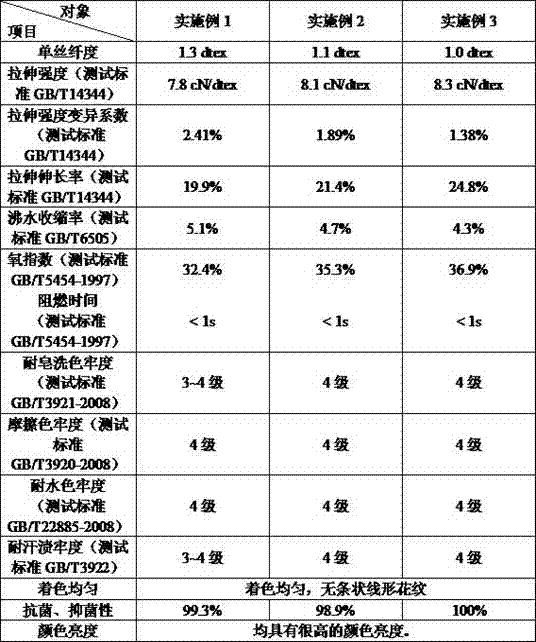

Embodiment 1

[0031] A preparation process for colored polyester fibers, the preparation steps are as follows:

[0032] S1. Drying: Dry the polyester fiber, polylactic acid flame retardant, and color masterbatch separately at a drying temperature of 110~120°C and a drying time of 1 h, and set aside;

[0033] The polylactic acid flame retardant is prepared by melt copolymerization of melamine or primary amine containing benzimidazole structure or o-phenylenediamine and lactic acid;

[0034] The color masterbatch is composed of 60 parts by weight of carrier, 15 parts of toner, 15 parts of dispersant, 4 parts of heat stabilizer, 4 parts of antibacterial agent, 4 parts of antioxidant and 3 parts of additive;

[0035] The carrier in the color masterbatch is prepared from the following raw materials in parts by weight: 20 parts of polyolefin, 15 parts of polyethylene terephthalate, and 10 parts of polyamide resin;

[0036] The dispersant in the masterbatch is any two of polyethylene wax, ethylen...

Embodiment 2

[0047] A preparation process for colored polyester fibers, the preparation steps are as follows:

[0048] S1. Drying: Dry the polyester fiber, polylactic acid flame retardant, and color masterbatch separately at a drying temperature of 110~120°C and a drying time of 1.5 h, and set aside;

[0049] The polylactic acid flame retardant is prepared by melt copolymerization of melamine or primary amine containing benzimidazole structure or o-phenylenediamine and lactic acid;

[0050] The color masterbatch consists of 60 parts by weight of carrier, 15 parts of toner, 15 parts of dispersant, 4 parts of heat stabilizer, 4 parts of antibacterial agent, 4 parts of antioxidant and 3 parts of additive;

[0051] The carrier in the color masterbatch is prepared from the following raw materials in parts by weight: 20 parts of polyolefin, 15 parts of polyethylene terephthalate, and 10 parts of polyamide resin;

[0052] The dispersant in the masterbatch is any two of polyethylene wax, ethylene...

Embodiment 3

[0063] A preparation process for colored polyester fibers, the preparation steps are as follows:

[0064] S1. Drying: Dry the polyester fiber, polylactic acid flame retardant, and color masterbatch separately at a drying temperature of 110-120°C and a drying time of 2 hours, and set aside;

[0065] The polylactic acid flame retardant is prepared by melt copolymerization of melamine or primary amine containing benzimidazole structure or o-phenylenediamine and lactic acid;

[0066] The color masterbatch consists of 60 parts by weight of carrier, 15 parts of toner, 15 parts of dispersant, 4 parts of heat stabilizer, 4 parts of antibacterial agent, 4 parts of antioxidant and 3 parts of additive;

[0067] The carrier in the color masterbatch is prepared from the following raw materials in parts by weight: 20 parts of polyolefin, 15 parts of polyethylene terephthalate, and 10 parts of polyamide resin;

[0068] The dispersant in the masterbatch is any two of polyethylene wax, ethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com