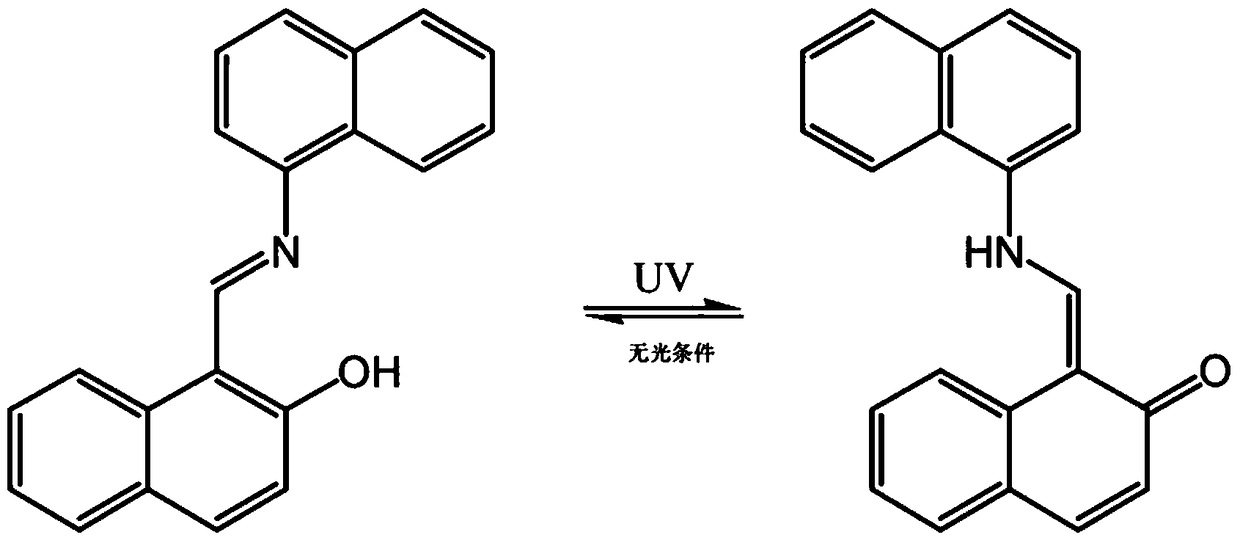

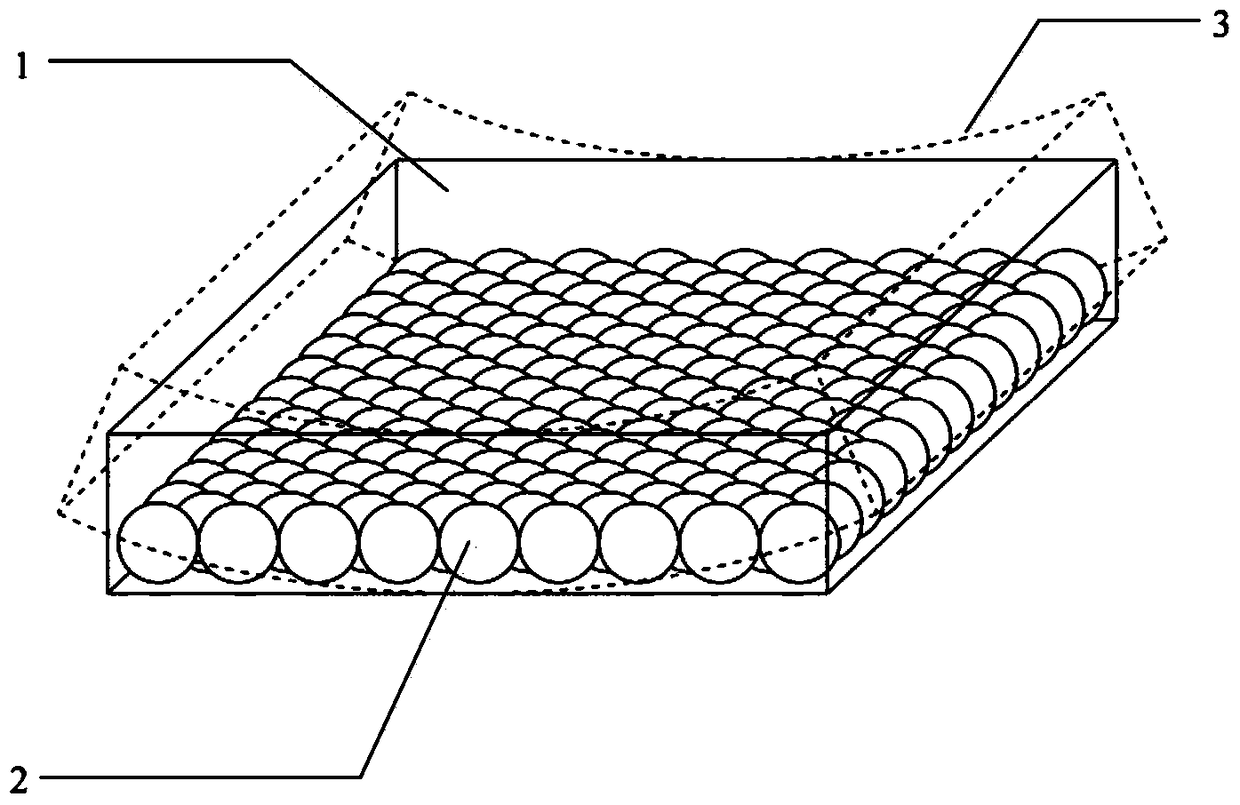

Ultraviolet light-driven molecular crystal-polymer composite film material and preparation method thereof

A polymer film and composite film technology, applied in the field of ultraviolet light-driven molecular crystal-polymer composite film material and its preparation, can solve the problems of fragility, low deformation accuracy, small deformation amount, etc., and achieves simple preparation, physical and chemical Stable properties and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

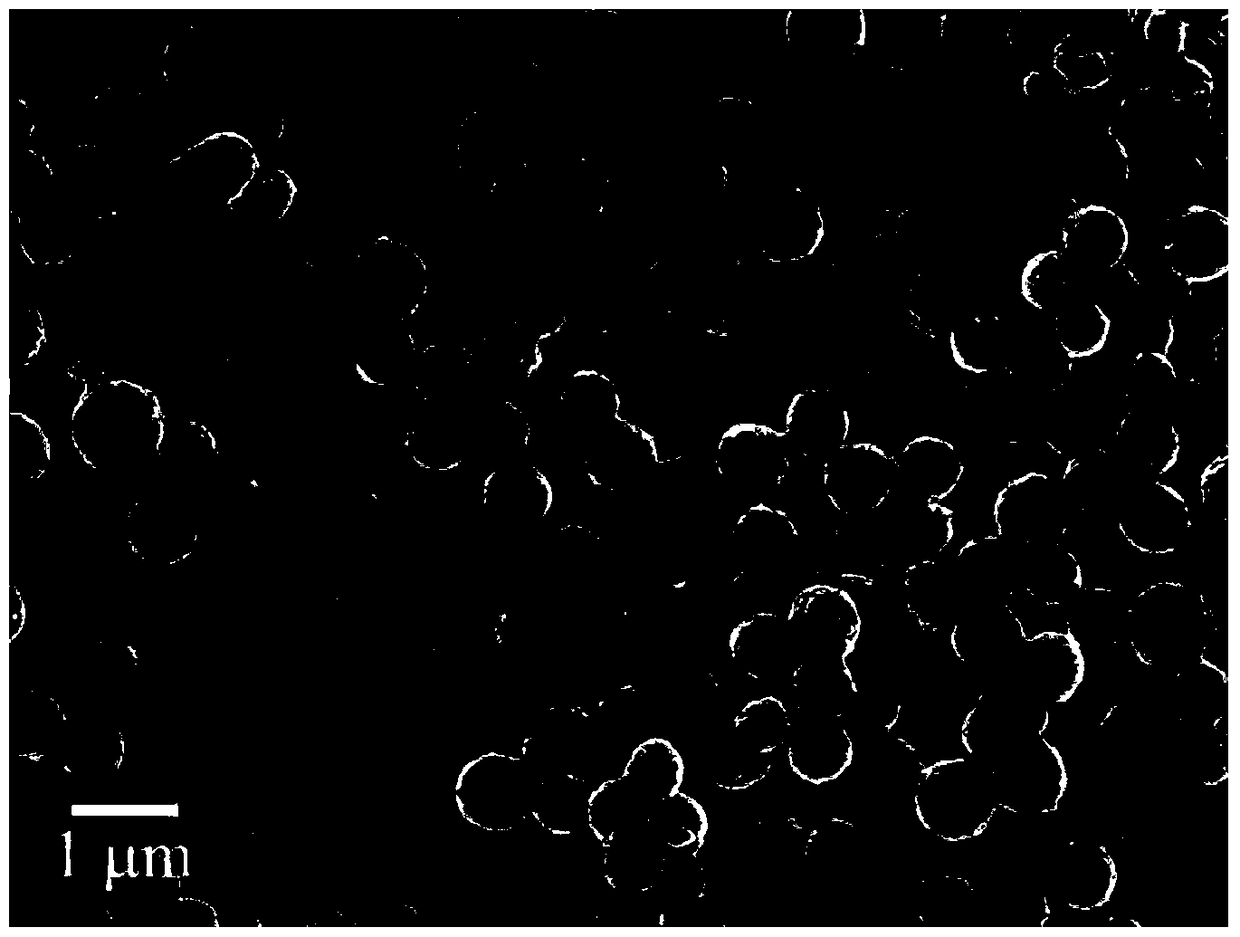

[0063] In the first step, about 50 mg of N-αnaphthyl-2-hydroxyl-1-naphthaldimine (HNNA), about 15 mL of cyclohexane, about 30 mL of ethanol and about 7.5 g of ethylene glycol were mixed to prepare a solution. Separately, an aqueous polyvinyl alcohol solution of about 30 mg / mL (dissolved at about 90° C. and then cooled to room temperature) was prepared.

[0064] In the second step, several 75mm×25mm glass slides are placed on a level-adjusted heating platform, and preheated to about 40°C. Then drop about 0.5mL of the HNNA mixed solution on each slide to make it cover the whole slide, and control the ambient temperature to about 25°C and the humidity to 2-3%RH.

[0065] In the third step, after the solvent evaporates, a mixture of yellow nanocrystals and ethylene glycol appears on the glass slide, which is washed and collected with deionized water, and the collected mixed liquid is centrifuged at a speed of about 4500 rpm for about 40 minute. Skim off the supernatant, re-add a...

Embodiment 2

[0074] Compared with Example 1, the difference of this example is that the collected HNNA nanocrystals and ethylene glycol mixture are purified by dialysis, and 100 mL of washing liquid is injected into a dialysis bag, which is placed in a deionized In the water, the water was changed every 24 hours, and the washing solution was taken out after 5 days to obtain the HNNA nanocrystal aqueous dispersion. In the dispersion obtained by this method, the nanocrystals are ball-rod mixtures.

Embodiment 3

[0076] Compared with Example 1, the difference of this example is that a saturated ethanol solution of HNNA was used to wash the HNNA nanocrystals, and the HNNA nanorods were obtained by filtration or centrifugation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com