Polyaniline-modified graphene conductive composite film and preparation method thereof

A graphene film and composite film technology, applied in the field of composite materials, can solve the problems of no chemical connection, insufficient electrical conductivity of polyaniline-graphene composites, cumbersome pickling process, etc., to achieve low cost, high electrical conductivity, The effect of process convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

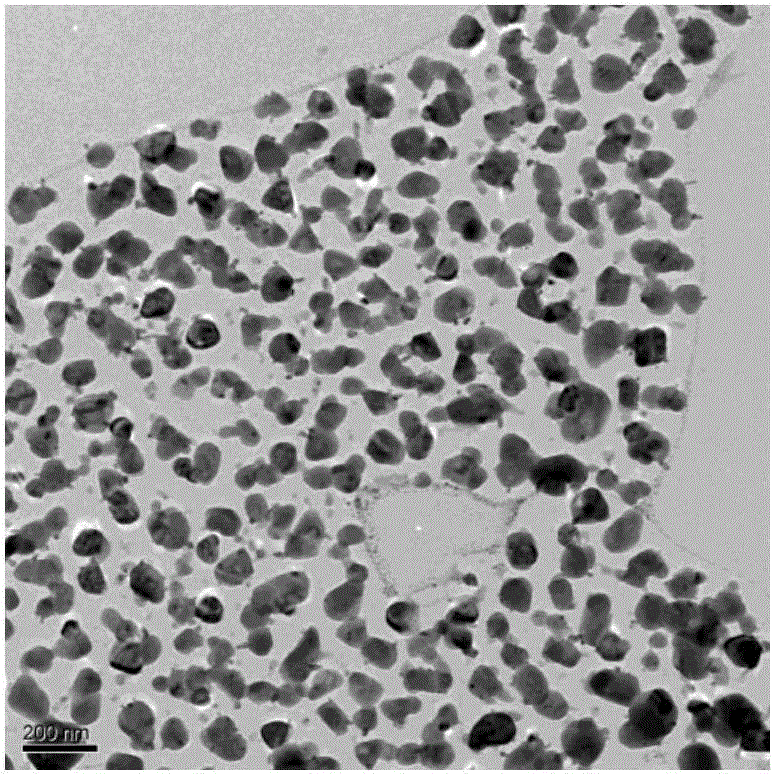

Image

Examples

Embodiment 1

[0036] A polyaniline-modified graphene conductive composite film of the present embodiment, the composite film is prepared from the following raw materials in parts by weight:

[0037] 1 part of graphene oxide film modified by polyaniline

[0038] Mass concentration is 8 parts of hydroiodic acid of 47%.

[0039] The above-mentioned polyaniline-modified graphene conductive composite film is prepared by the following method, comprising the steps of:

[0040] (1) In situ polymerization to prepare polyaniline-modified graphene oxide

[0041] Weigh 1 part of graphene oxide, ultrasonically disperse it in 50ml of dilute hydrochloric acid with a mass concentration of 2%, then add 0.1 part of aniline monomer, stir for 1 hour at a temperature of 10°C, and then add 0.1 part of ammonium persulfate powder Initiate in-situ polymerization, react at a temperature of 10°C for 5 hours, after the reaction, centrifuge the reaction product, take the lower layer of sediment and ultrasonically dispe...

Embodiment 2

[0049] A polyaniline-modified graphene conductive composite film of the present embodiment, the composite film is prepared from the following raw materials in parts by weight:

[0050] 1 part of graphene oxide film modified by polyaniline

[0051] Mass concentration is 15 parts of hydroiodic acid of 47%.

[0052] The above-mentioned polyaniline-modified graphene conductive composite film is prepared by the following method, comprising the steps of:

[0053] (1) In situ polymerization to prepare polyaniline-modified graphene oxide

[0054] Weigh 1 part of graphene oxide, ultrasonically disperse it in 50ml of dilute hydrochloric acid with a mass concentration of 5%, then add 0.3 part of aniline monomer, stir for 2 hours at a temperature of 20°C, and then add 0.3 part of ammonium persulfate powder Initiate in-situ polymerization and react at a temperature of 20°C for 8 hours. After the reaction, the reaction product is centrifuged, and the lower layer of sediment is ultrasonica...

Embodiment 3

[0061] A polyaniline-modified graphene conductive composite film of the present embodiment, the composite film is prepared from the following raw materials in parts by weight:

[0062] 1 part of graphene oxide film modified by polyaniline

[0063] Mass concentration is 23 parts of hydroiodic acid of 47%.

[0064] The above-mentioned polyaniline-modified graphene conductive composite film is prepared by the following method, comprising the steps of:

[0065] (1) In situ polymerization to prepare polyaniline-modified graphene oxide

[0066] Weigh 1 part of graphene oxide, ultrasonically disperse it in 50ml of dilute hydrochloric acid with a mass concentration of 8%, then add 0.5 part of aniline monomer, stir for 5 hours at a temperature of 30°C, and then add 0.5 part of ammonium persulfate powder Initiate in-situ polymerization and react at a temperature of 30°C for 10 hours. After the reaction, centrifuge the reaction product, take the lower layer of sediment and ultrasonical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com