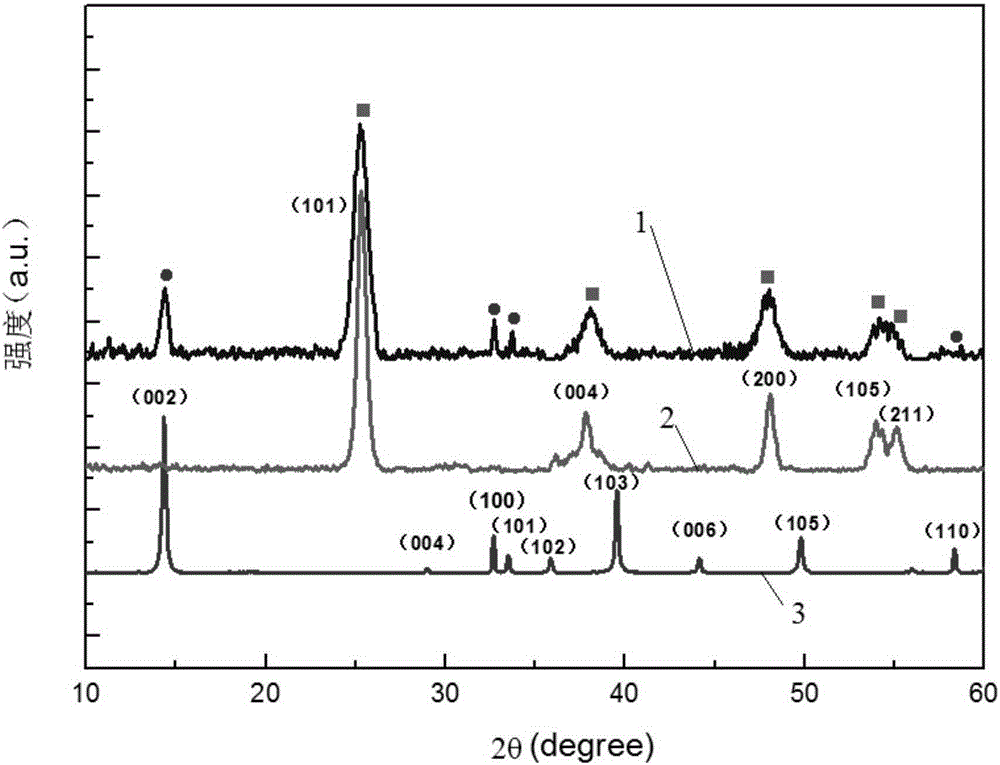

Preparation method of molybdenum disulfide-black titanium dioxide composite visible-light-driven photocatalyst for hydrogen production

A technology of black titanium dioxide and molybdenum disulfide, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve low hydrogen production efficiency, low utilization rate of visible light, etc. problems, to achieve the effect of high hydrogen production efficiency, efficient hydrogen production capacity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific Embodiment 1: This embodiment is a method for preparing a molybdenum disulfide / black titanium dioxide composite visible light catalyst for hydrogen production, specifically as follows:

[0021] 1. Mixing of reagents: uniformly mix tetrabutyl titanate and concentrated hydrochloric acid, then add molybdenum disulfide, then add oleic acid, and stir for 1h to 1.5h to obtain a mixed reagent; the concentrated hydrochloric acid and tetrabutyl titanate The volume ratio of the molybdenum disulfide is 1:(2~2.5); the volume ratio of the mass of the molybdenum disulfide to the tetrabutyl titanate is 1g:(8mL~9mL); the tetrabutyl titanate and the oleic acid The volume ratio is 1:(6.25~6.5);

[0022] 2. Hydrothermal reaction: put the mixed reagent obtained in step 1 in a reaction kettle, keep it warm for 2h-6h at a temperature of 160°C-200°C, cool it down to room temperature naturally, wash it with deionized water, and then Dry at 80°C for 12 hours to obtain a mixed powder; ...

specific Embodiment approach 2

[0025] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the volume ratio of concentrated hydrochloric acid and tetrabutyl titanate described in step 1 is 1:2. Others are the same as the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volume ratio of the mass of molybdenum disulfide described in step 1 to tetrabutyl titanate is 1g:8mL. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com