Natural gas hydrate reservoir sand prevention device

A technology for hydrate and natural gas, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve problems such as inability to effectively achieve capillary seepage drainage and gas production, low sand control accuracy, and inability to achieve micron-level sand control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

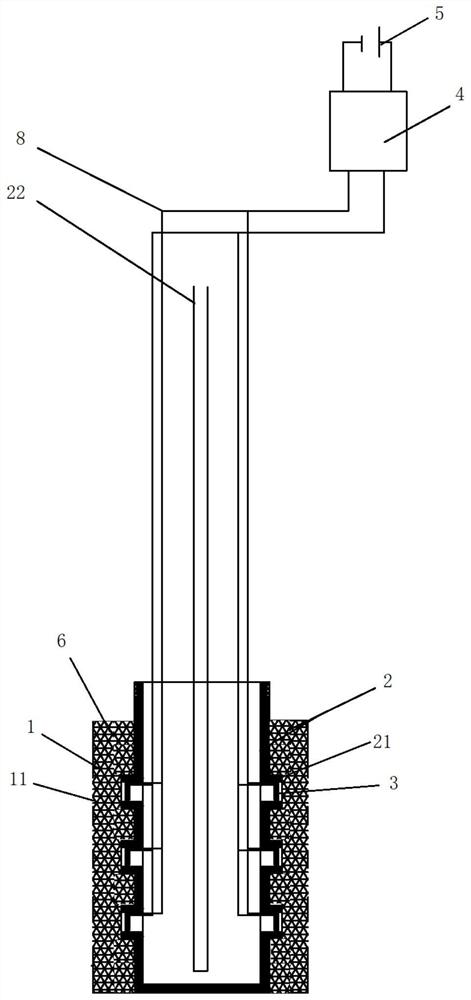

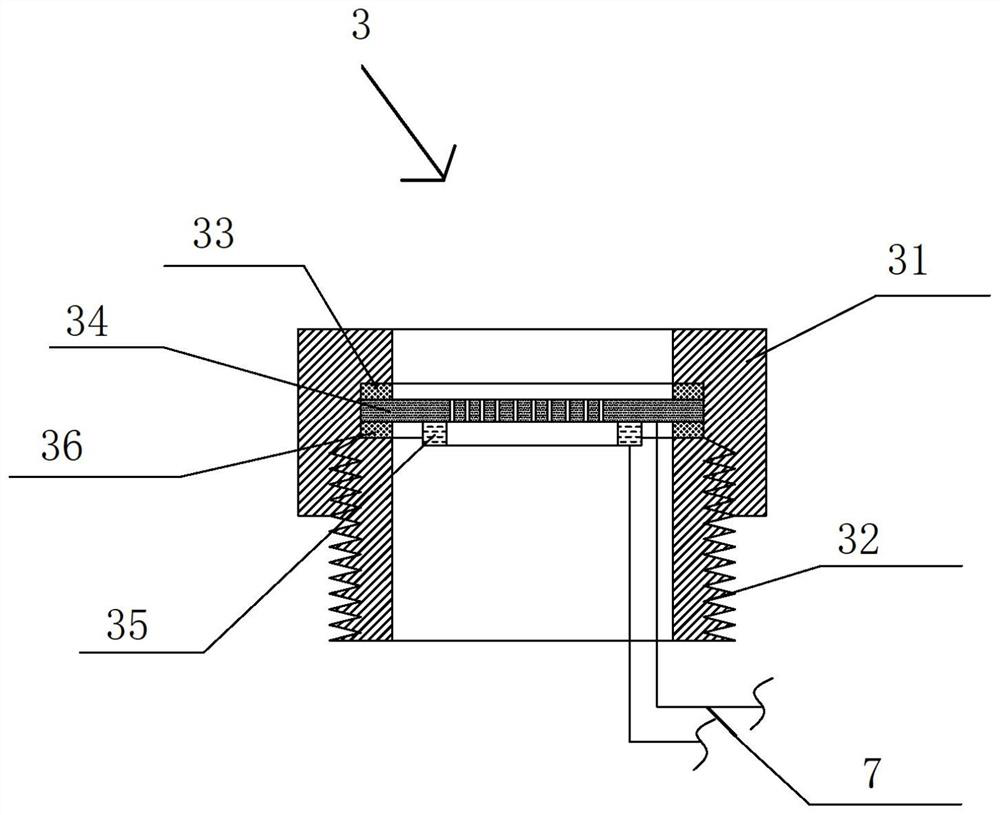

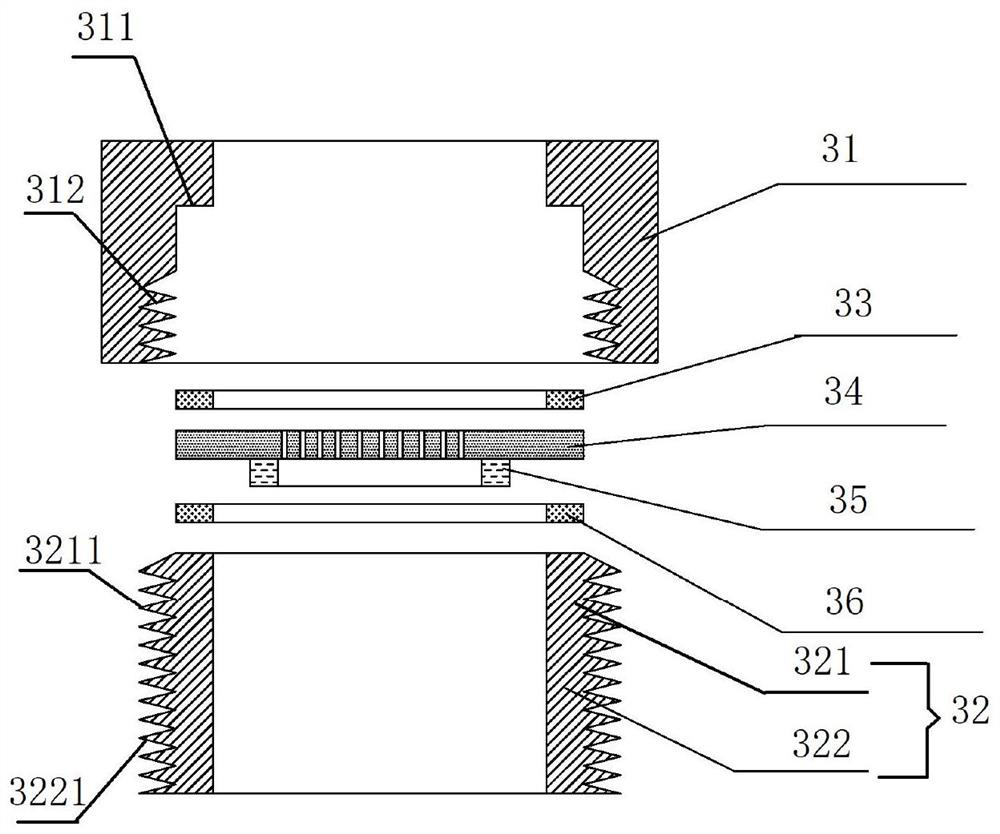

[0020] Please refer to figure 1 The embodiment of the present invention provides a sand control device for natural gas hydrate reservoirs, including a sand control cylinder 1, a base pipe 2, several sand control units 3, a drive circuit 4 and a power supply 5, and the drive circuit 4 and the power supply 5 are set separately.

[0021] The sand retaining cylinder 1 is a hollow structure with an open top, and several through holes 11 are opened on the side wall of the sand retaining cylinder 1; in this embodiment, the sand retaining cylinder 1 can be a wire-wrapped screen.

[0022] The base pipe 2 is a hollow structure with an open top. The base pipe 2 is located in the sand retaining cylinder 1. The sand retaining medium 6 is filled between the side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com