Tail gas recovery process and device for protective gas in hot-dip galvanizing production line

A tail gas recovery and production line technology, applied in hot dip plating process, metal material coating process, coating and other directions, can solve the problems of unstable protective gas pressure, pollute the environment, low resource utilization rate, etc., and solve the problem of resource utilization rate Low environmental pollution, cost saving, and the effect of solving pressure instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

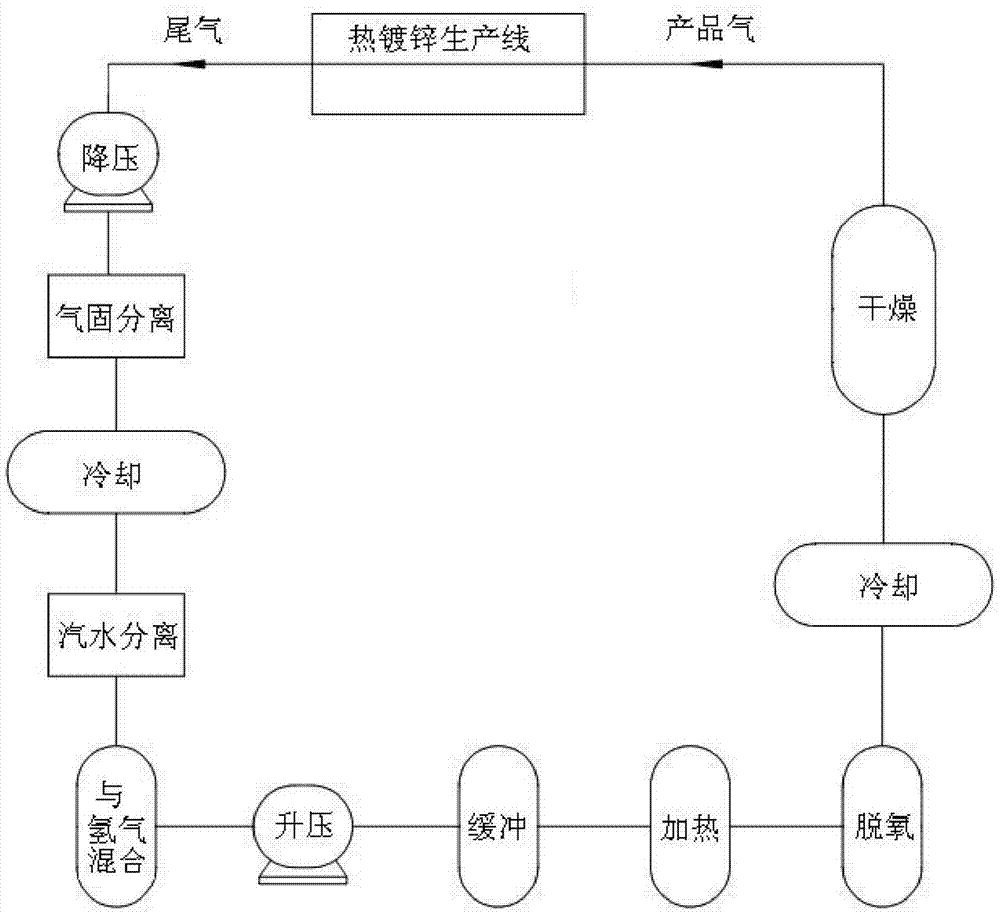

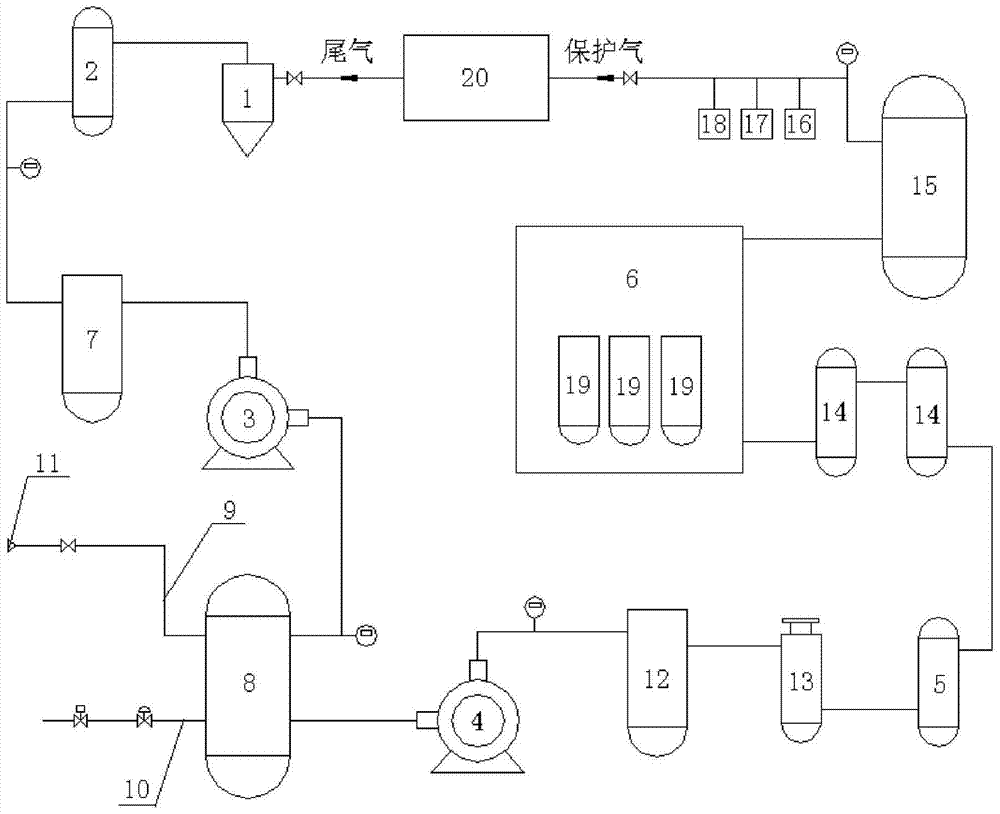

[0053] The tail gas recovery process of the protective gas of the hot-dip galvanizing production line described in this embodiment, such as figure 1 shown, including the following steps:

[0054] (1) The relative pressure of the tail gas of the protective gas of the hot-dip galvanizing production line is adjusted to 1k Pa;

[0055] (2) the tail gas after step (1) pressure regulation is sent into the cyclone separator with a speed of 10 m / s to carry out gas-solid separation, and collect the gas phase;

[0056] (3) cooling the gas phase obtained in step (2) to 30°C;

[0057] (4) step (3) gas phase after cooling is carried out boosting treatment;

[0058] (5) At 120°C, the volumetric space velocity is 5000h -1 Under the condition that adopts palladium catalyst deoxidizer to carry out deoxidation treatment to the gas phase after step (4) boosting;

[0059] (6) Using molecular sieve as desiccant, at 10°C, volumetric space velocity is 1000h -1 The gas phase after step (5) deoxi...

Embodiment 2

[0062] The tail gas recovery process of the protective gas of the hot-dip galvanizing production line described in this embodiment, such as figure 1 shown, including the following steps:

[0063] (1) Adjust the relative pressure of the tail gas of the protective gas of the hot-dip galvanizing production line to 0.01k Pa;

[0064] (2) the tail gas after the step (1) pressure regulation is sent into the cyclone separator with a speed of 20 m / s to carry out gas-solid separation, and collect the gas phase;

[0065] (3) The gas phase obtained in step (2) is cooled to 20° C., and then the cooled gas phase is further cooled to 8.5° C. to completely remove solid matter and saturated water vapor in the gas phase; Hydrogen is mixed until the volume content of hydrogen in the mixed gas is 20%;

[0066] (4) pressurizing the mixed gas in step (3);

[0067] (5) At 80°C, the volumetric space velocity is 5000h -1 Under the condition that adopts palladium catalyst deoxidizer to carry out d...

Embodiment 3

[0071] The tail gas recovery process of the protective gas of the hot-dip galvanizing production line described in this embodiment, such as figure 1 shown, including the following steps:

[0072] (1) Adjust the relative pressure of the tail gas of the protective gas of the hot-dip galvanizing production line to 0.5k Pa;

[0073] (2) the tail gas after step (1) pressure regulation is sent in the cyclone separator with the speed of 30 m / s and carries out gas-solid separation, collects gas phase;

[0074] (3) cooling the gas phase obtained in step (2) to 10°C;

[0075] (4) step (3) gas phase after cooling is carried out boosting treatment;

[0076] (5) Heating the gas phase after step (4) to 90°C, and then at 100°C, the volume space velocity is 5000h -1 Under certain conditions, the heated gas phase is deoxidized using a palladium catalyst deoxidizer, and the temperature of the deoxidized gas phase is lowered to 35°C;

[0077] (6) Using molecular sieve as desiccant, at 22°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com