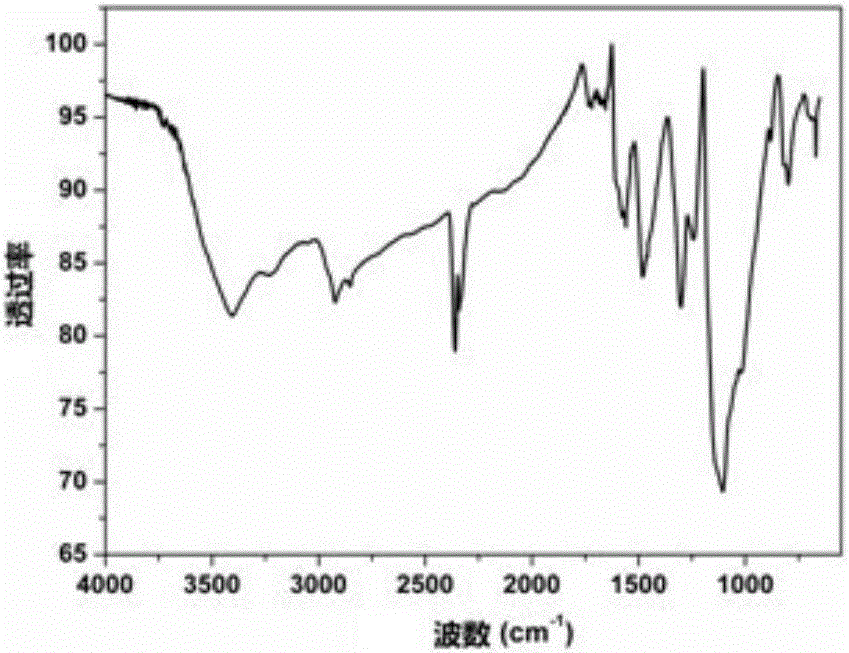

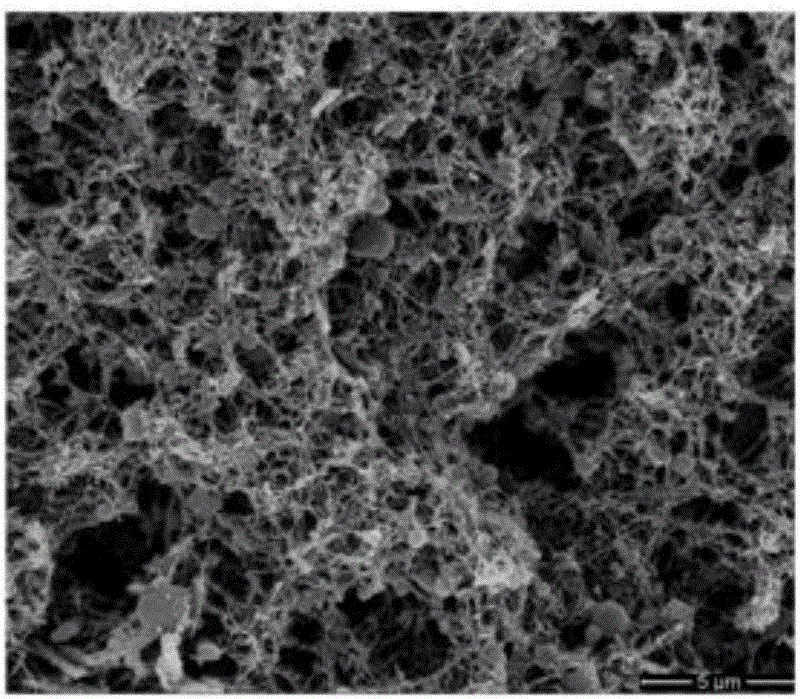

Conductive polymer aerogel and preparation method thereof

A conductive polymer and airgel technology, applied in the field of conductive polymer airgel material and its preparation, can solve the problems of difficult preparation of conductive polymer hydrogel, poor mechanical properties of airgel, etc., and achieve easy control And industrial production, excellent physical and mechanical properties and electrical conductivity, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of conductive polymer airgel, comprising the following steps:

[0033] Step 1. Add 4g of low-ester pectin into 100mL of deionized water, stir at 800r / min for 10min to dissolve, then add 6g of aniline at 0°C, and continue stirring for 3h to dissolve to obtain a mixed solution;

[0034] Step 2. Add 3 g of ammonium persulfate to the mixed solution in Step 1 at 0°C, and stir at 800 r / min until the color of the solution turns black; then keep the temperature unchanged for 24 hours to obtain a hydrogel;

[0035] Step 3, add the obtained hydrogel into a container with fresh deionized water for soaking and washing, and replace fresh deionized water every day for 5 days; the impurity in the hydrogel is removed during the soaking and washing process, so that only polyaniline and low-ester pectin;

[0036] Step 4, adding the soaked and washed hydrogel into a container filled with fresh ethanol for solvent exchange, replacing fresh ethanol every day for 7 days...

Embodiment 2

[0040] A preparation method of conductive polymer airgel, comprising the following steps:

[0041] Step 1. Add 4g of low-ester pectin into 96mL of deionized water, stir at 1000r / min for 30min to dissolve, then add 4g of aniline at 4°C, continue stirring for 3h to dissolve, and obtain a mixed solution;

[0042]Step 2. Add 2 g of ammonium persulfate to the mixed solution in Step 1 at 4°C, and stir at 1000 r / min until the color of the solution turns black; then keep the temperature unchanged for 24 hours to obtain a hydrogel;

[0043] Step 3, add the obtained hydrogel into a container with fresh deionized water for soaking and washing, and replace fresh deionized water every day for 5 days; the impurity in the hydrogel is removed during the soaking and washing process, so that only polyaniline and low-ester pectin;

[0044] Step 4, adding the soaked and washed hydrogel into a container filled with fresh ethanol for solvent exchange, replacing fresh ethanol every day for 7 days; ...

Embodiment 3

[0048] A preparation method of conductive polymer airgel, comprising the following steps:

[0049] Step 1. Add 4g of low-ester pectin into 96mL of deionized water, stir at 800r / min for 30min to dissolve, then add 1.7g of aniline at 2°C, and continue stirring for 3h to dissolve to obtain a mixed solution;

[0050] Step 2. Add 0.85 g of ammonium persulfate to the mixed solution in Step 1 at 2°C, and stir at 800 r / min until the color of the solution turns black; then keep the temperature unchanged for 24 hours to obtain a hydrogel;

[0051] Step 3, add the obtained hydrogel into a container with fresh deionized water for soaking and washing, and replace fresh deionized water every day for 5 days; the impurity in the hydrogel is removed during the soaking and washing process, so that only polyaniline and low-ester pectin;

[0052] Step 4. Quickly freeze the soaked and washed hydrogel at -196°C until the ice crystals grow completely, and freeze at room temperature until completely...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com