A kind of transparent hydrogenated polystyrene-b-randomly copolymerized conjugated diene/styrene resin and preparation method thereof

A technology for hydrogenating polystyrene and styrene resin, applied in the field of modified styrene-butadiene resin materials, can solve the problems of aging resistance, short service life, easy yellowing and cracking, etc., and achieve low turbidity and fracture of products. High elongation and clear surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

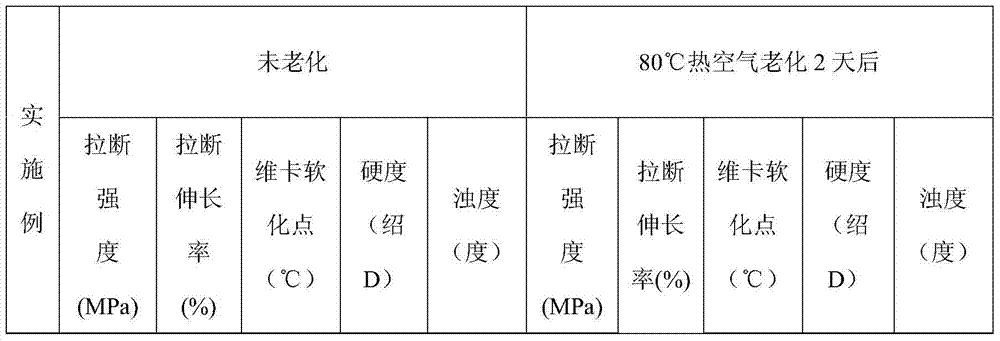

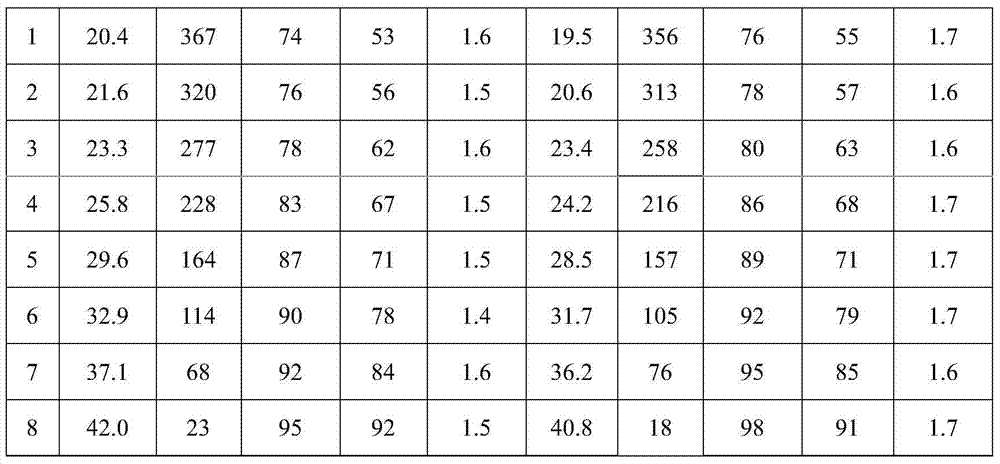

Examples

Embodiment 1

[0048] Add 3500mL of cyclohexane solution with a mass fraction of 10% n-hexane in a 5-liter steel polymerization kettle under nitrogen protection, then add 1.36mL tetrahydrofurfuryl alcohol ethyl ether, and heat up to 50-60°C with hot water Finally, add 80g of styrene into the polymerization kettle and start stirring, then inject 12mL of 0.5mol / L n-butyllithium into the polymerization kettle with a syringe, and react for 20-25min; then add 292.5g of butadiene and 77.5g of benzene The mixed monomer of ethylene and 0.03mL of divinylbenzene was reacted at 50-75°C for 25 minutes; the mass content of vinyl in the butadiene segment in the polymer was measured to be 50.6%, and the number average molecular weight of the polymer Mn=82000.

[0049] Then, after the polymer is pressed into the hydrogenation tank, 0.13 g of dicyclopentadiene titanium dichloride with a mass fraction of 99% is added, the hydrogen pressure is controlled at 1.2 MPa, and the hydrogenation The glue was moved int...

Embodiment 2

[0051] Add 3500mL of cyclohexane solution with a mass fraction of 10% n-hexane in a 5-liter steel polymerization kettle under nitrogen protection, then add 1.54mL tetrahydrofurfuryl alcohol ethyl ether, and heat up to 50-60°C with hot water Finally, add 100g of styrene into the polymerization kettle and start stirring, then inject 11mL of 0.5mol / L n-butyllithium into the polymerization kettle with a syringe, and react for 20-25min; then add 247.5g of butadiene and 102.5g of benzene The mixed monomer of ethylene and 0.04mL of divinylbenzene reacted at 50-75°C for 25 minutes; the vinyl mass content of the butadiene segment in the polymer was measured to be 57.6%, and the number-average molecular weight of the polymer Mn=96000.

[0052] Then, after the polymer is pressed into the hydrogenation tank, 0.14 g of dicyclopentadiene titanium dichloride with a mass fraction of 99% is added, the hydrogen pressure is controlled at 1.3 MPa, and the hydrogenation The glue was moved into the...

Embodiment 3

[0054] Add 3500mL of cyclohexane solution with a mass fraction of 10% n-hexane in a 5-liter steel polymerization kettle under nitrogen protection, then add 1.60mL of ditetrahydrofurfurfurylpropane, and heat up to 50-60°C with hot water Finally, add 140g of styrene into the polymerization kettle and start stirring, then inject 10mL of 0.5mol / L n-butyllithium into the polymerization kettle with a syringe, and react for 20-25min; then add 202.5g of butadiene and 107.5g of benzene The mixed monomer of ethylene and 0.06mL of divinylbenzene reacted at 50-75°C for 25 minutes; the vinyl mass content of the butadiene segment in the polymer was measured to be 62.5%, and the number-average molecular weight of the polymer Mn=104000.

[0055] Then, after the polymer was pressed into the hydrogenation tank, 0.14 g of dicyclopentadiene titanium dichloride with a mass fraction of 99% was added, the hydrogen pressure was controlled at 1.5 MPa, and the hydrogenation The glue was moved into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com