Transparent hydrogenated polystyrene-b-random copolymerized conjugated diene/styrene resin and preparation method therefor

A technology for hydrogenating polystyrene and styrene resin, applied in the field of modified styrene-butadiene resin materials, can solve the problems of aging resistance, easy yellowing and cracking, short service life, and achieve low turbidity and surface Clear, high elongation at break effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

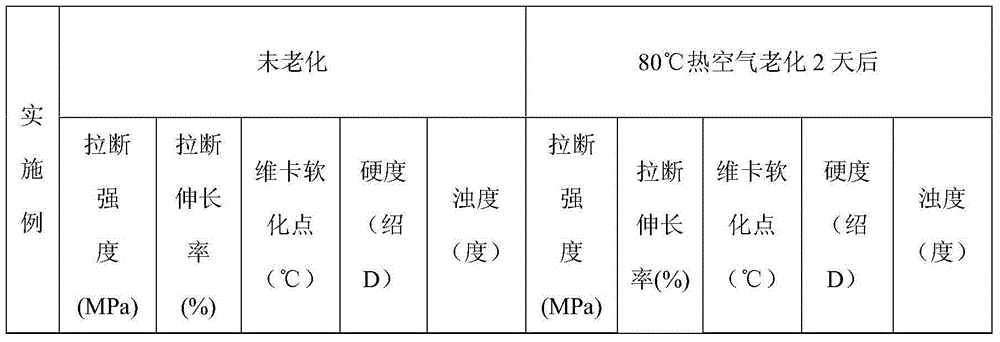

Examples

Embodiment 1

[0048] Add 3500mL of cyclohexane solution with a mass fraction of 10% n-hexane in a 5-liter steel polymerization kettle under nitrogen protection, then add 1.36mL tetrahydrofurfuryl alcohol ethyl ether, and heat up to 50-60°C with hot water Finally, add 80g of styrene into the polymerization kettle and start stirring, then inject 12mL of 0.5mol / L n-butyllithium into the polymerization kettle with a syringe, and react for 20-25min; then add 292.5g of butadiene and 77.5g of benzene The mixed monomer of ethylene and 0.03mL of divinylbenzene was reacted at 50-75°C for 25 minutes; the mass content of vinyl in the butadiene segment in the polymer was measured to be 50.6%, and the number average molecular weight of the polymer Mn=82000.

[0049] Then, after the polymer is pressed into the hydrogenation tank, 0.13 g of dicyclopentadiene titanium dichloride with a mass fraction of 99% is added, the hydrogen pressure is controlled at 1.2 MPa, and the hydrogenation The glue was moved int...

Embodiment 2

[0051] Add 3500mL of cyclohexane solution with a mass fraction of 10% n-hexane in a 5-liter steel polymerization kettle under nitrogen protection, then add 1.54mL tetrahydrofurfuryl alcohol ethyl ether, and heat up to 50-60°C with hot water Finally, add 100g of styrene into the polymerization kettle and start stirring, then inject 11mL of 0.5mol / L n-butyllithium into the polymerization kettle with a syringe, and react for 20-25min; then add 247.5g of butadiene and 102.5g of benzene The mixed monomer of ethylene and 0.04mL of divinylbenzene reacted at 50-75°C for 25 minutes; the vinyl mass content of the butadiene segment in the polymer was measured to be 57.6%, and the number-average molecular weight of the polymer Mn=96000.

[0052] Then, after the polymer is pressed into the hydrogenation tank, 0.14 g of dicyclopentadiene titanium dichloride with a mass fraction of 99% is added, the hydrogen pressure is controlled at 1.3 MPa, and the hydrogenation The glue was moved into the...

Embodiment 3

[0054] Add 3500mL of cyclohexane solution with a mass fraction of 10% n-hexane in a 5-liter steel polymerization kettle under nitrogen protection, then add 1.60mL of ditetrahydrofurfurfurylpropane, and heat up to 50-60°C with hot water Finally, add 140g of styrene into the polymerization kettle and start stirring, then inject 10mL of 0.5mol / L n-butyllithium into the polymerization kettle with a syringe, and react for 20-25min; then add 202.5g of butadiene and 107.5g of benzene The mixed monomer of ethylene and 0.06mL of divinylbenzene reacted at 50-75°C for 25 minutes; the vinyl mass content of the butadiene segment in the polymer was measured to be 62.5%, and the number-average molecular weight of the polymer Mn=104000.

[0055] Then, after the polymer was pressed into the hydrogenation tank, 0.14 g of dicyclopentadiene titanium dichloride with a mass fraction of 99% was added, the hydrogen pressure was controlled at 1.5 MPa, and the hydrogenation The glue was moved into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com