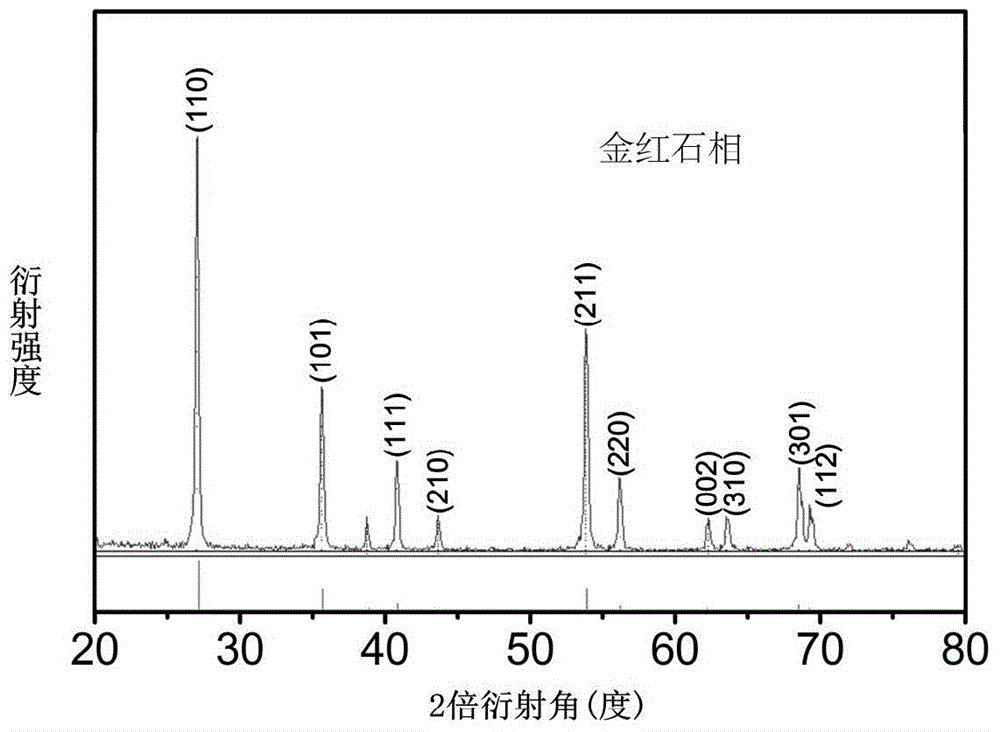

Method for preparing rutile titanium dioxide nano-film by virtue of sol-gel method

The technology of rutile titanium dioxide and sol-gel method is applied in the field of preparing rutile titanium dioxide nano-film by sol-gel method, which can solve the problems of short precursor sol gelation time, difficulty in guaranteeing precursor consistency, and high waste rate of sol raw materials, and achieves The effect of stable structure, long gel time and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

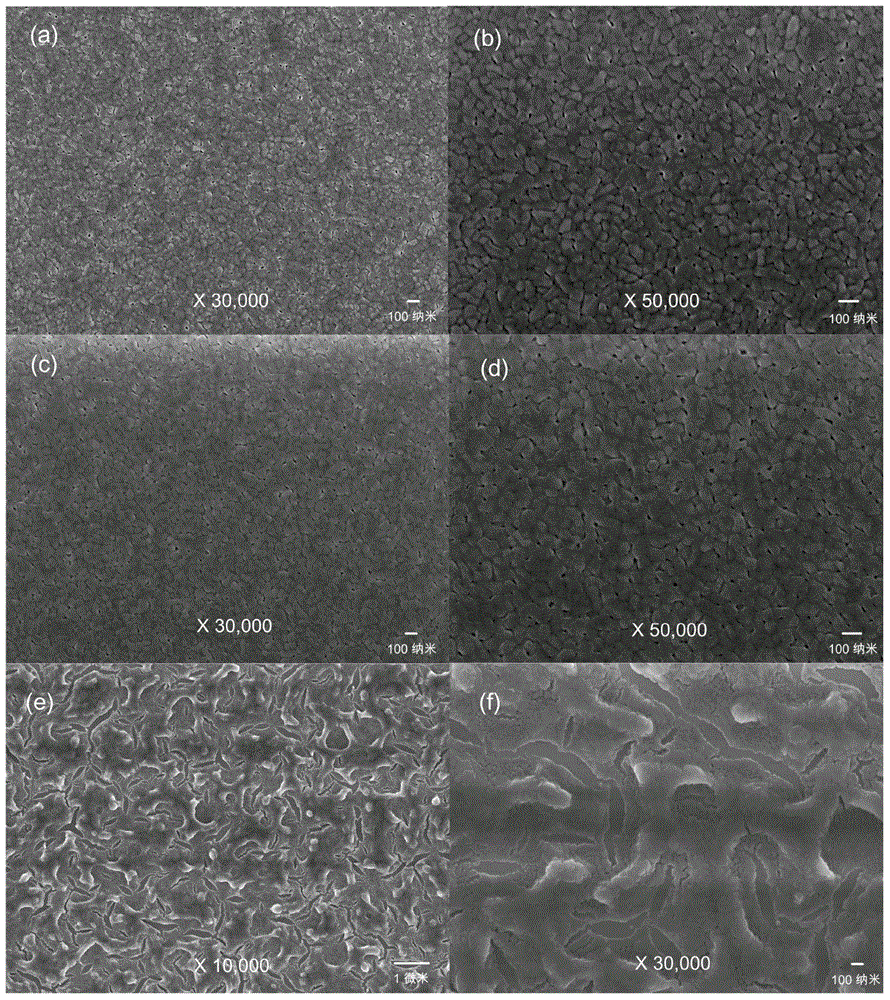

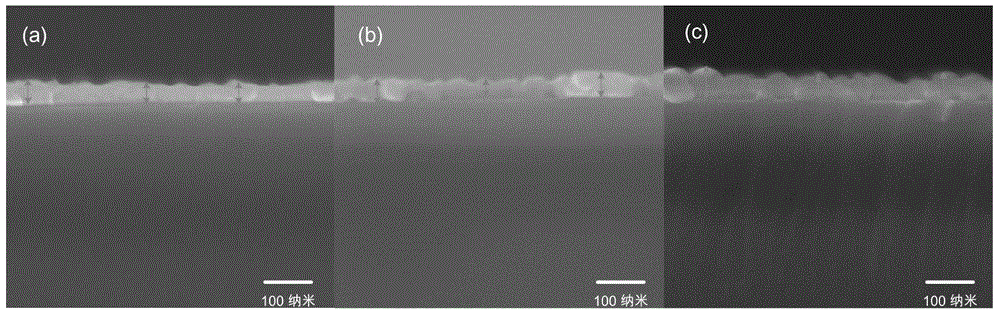

Embodiment 1

[0017] A kind of sol-gel method prepares the method for rutile titanium dioxide nano film, specifically comprises the following steps:

[0018] Step 1: Tetrabutyl titanate (Ti(OBu) 4 ) is a solute, and the mixed solution of monoethanol ammonia, ethylene glycol methyl ether and acetone is a solvent, and the concentration of tetrabutyl titanate for preparation is a precursor solution of 0.1mol / L; wherein, monoethanol ammonia, ethylene glycol methyl ether The volume ratio with acetone is 1:1:0.5;

[0019] Step 2: Add acetylacetone to the precursor solution obtained in step 1 as a chelating agent, glycerol as a tackifier, and magnetically stir at room temperature to obtain a transparent and uniform sol; wherein, the molar ratio of tetrabutyl titanate to acetylacetone It is 1:1, and the volume percentage of glycerol is 5%;

[0020] Step 3: Spin-coat the sol obtained in Step 2 on the cleaned silicon wafer at a spin-coating speed of 2000 rpm, and then dry it in an oven at 200°C to ...

Embodiment 2

[0022] A kind of sol-gel method prepares the method for rutile titanium dioxide nano film, specifically comprises the following steps:

[0023] Step 1: Tetrabutyl titanate (Ti(OBu) 4 ) is a solute, and the mixed solution of monoethanol ammonia, ethylene glycol methyl ether and acetone is a solvent, and the concentration of tetrabutyl titanate for preparation is a precursor solution of 0.2mol / L; wherein, monoethanol ammonia, ethylene glycol methyl ether The volume ratio with acetone is 1:1:0.5;

[0024] Step 2: Add acetylacetone to the precursor solution obtained in step 1 as a chelating agent, glycerol as a tackifier, and magnetically stir at room temperature to obtain a transparent and uniform sol; wherein, the molar ratio of tetrabutyl titanate to acetylacetone It is 1:3, and the volume percentage of glycerol is 5%;

[0025] Step 3: Spin-coat the sol obtained in Step 2 on the cleaned silicon wafer at a spin-coating speed of 3000 rpm, and then dry it in an oven at 275°C to ...

Embodiment 3

[0027] A kind of sol-gel method prepares the method for rutile titanium dioxide nano film, specifically comprises the following steps:

[0028] Step 1: Tetrabutyl titanate (Ti(OBu) 4 ) is a solute, and the mixed solution of monoethanol ammonia, ethylene glycol methyl ether and acetone is a solvent, and the concentration of tetrabutyl titanate for preparation is a precursor solution of 0.4mol / L; wherein, monoethanol ammonia, ethylene glycol methyl ether The volume ratio with acetone is 1:1:0.5;

[0029] Step 2: Add acetylacetone to the precursor solution obtained in step 1 as a chelating agent, glycerol as a tackifier, and magnetically stir at room temperature to obtain a transparent and uniform sol; wherein, the molar ratio of tetrabutyl titanate to acetylacetone It is 1:2, and the volume percentage of glycerol is 5%;

[0030] Step 3: Spin-coat the sol obtained in Step 2 on the cleaned silicon wafer at a spin-coating speed of 2000 rpm, and then dry it in an oven at 200°C to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com