Curved glass cleaning machine

A curved glass and cleaning machine technology, applied in the field of glass processing, can solve the problems of unfavorable energy saving, high energy, easy to scratch the surface of parts, etc., and achieve the effects of improving stability, saving water resources and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

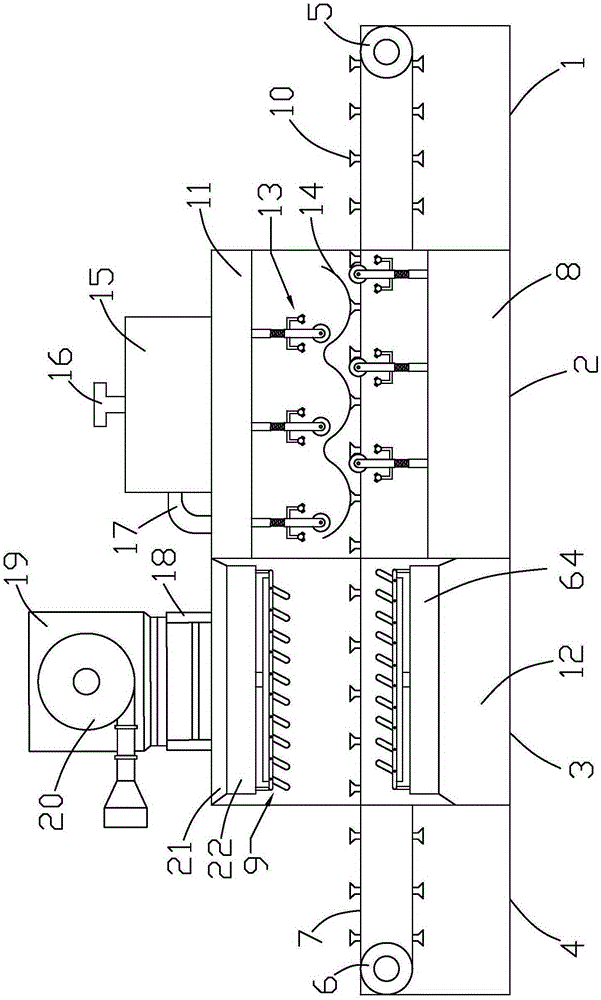

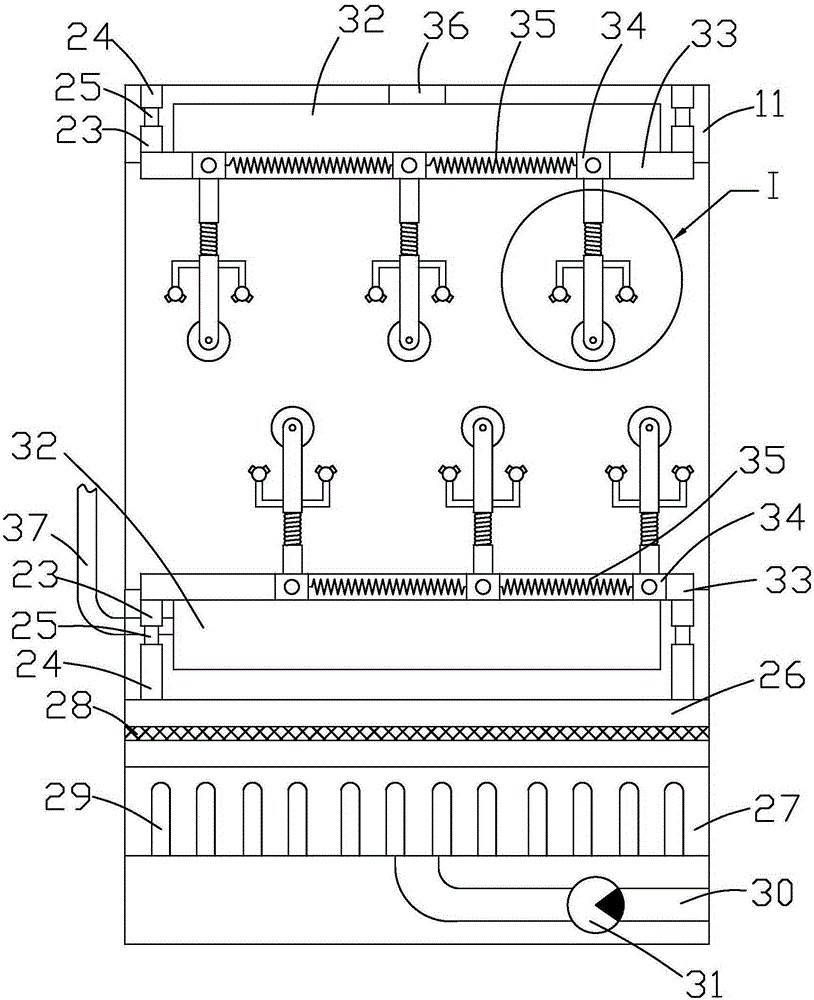

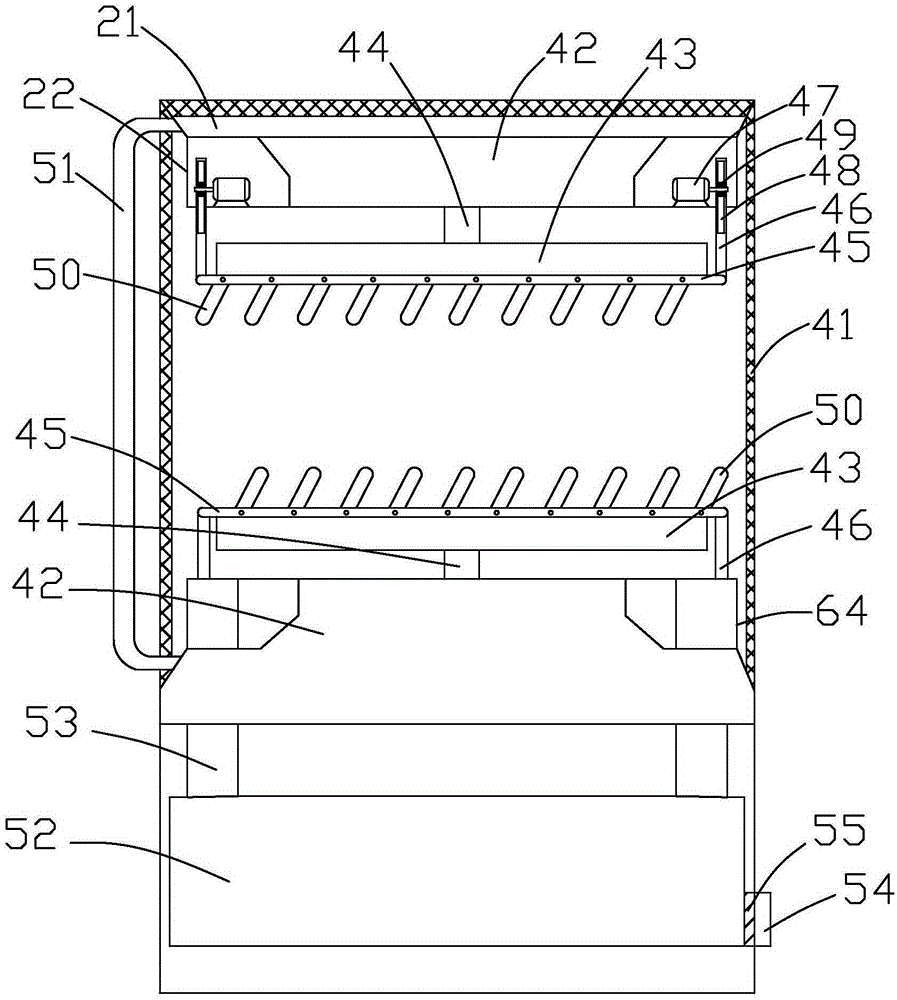

[0029] Such as Figure 1 to Figure 5 As shown, it is a curved glass cleaning machine of the present invention. The curved glass cleaning machine includes a feed box 1, a cleaning box 2, a drying box 3 and a discharge box 4. The feed box 1 and the discharge box 4 are respectively provided with active The wheel 5 and the driven wheel 6, the driving wheel 5 passes through the cleaning box 2 and the drying box 3 to connect the driven wheel 6 through the conveyor belt 7, the elastic suction head 10 is evenly arranged on the conveyor belt 7, and the top and bottom of the elastic suction head 10 are respectively provided with flexible and breathable Net 39 and air vent 40, the inside of elastic suction head 10 is provided with unidirectional air guide plate 63, the middle part of unidirectional air guide plate 63 connects the inner wall of elastic adsorption head 10 by extruding spring 38, and flexible breathable net 39 can improve curved surface glass 14 contact area, so that the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com