A kind of galvanized plastic-sprayed malleable steel pipe fitting and its preparation method

A technology of spraying plastic malleable steel pipe and zinc malleable steel pipe, which is applied in the direction of pipes/pipe joints/pipes, pipes, branch pipelines, etc., can solve the problem that the rust prevention effect of galvanized malleable steel pipe fittings is not very good, and the service life of galvanized malleable steel pipe fittings is affected. , increase the consumption of protective paint materials, etc., to achieve the effect of improving outdoor ultraviolet radiation resistance and rust resistance, good acid and alkali resistance, broadening the scope of use and environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

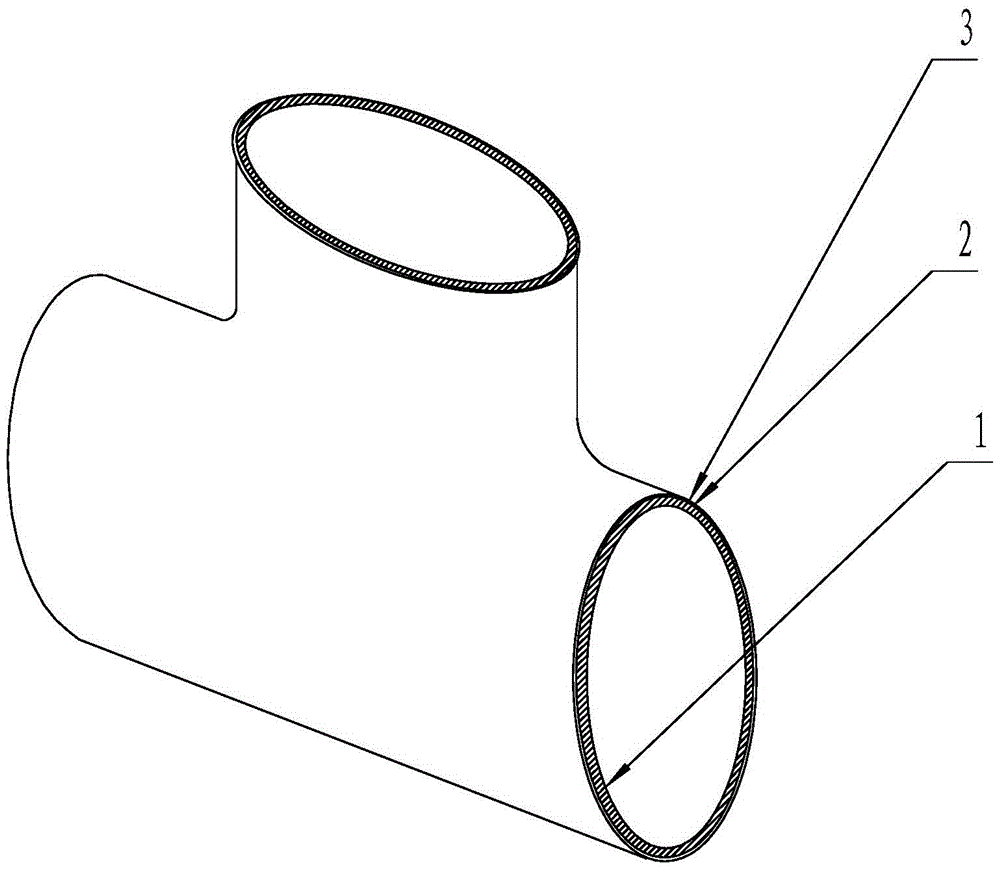

[0023] 1. If figure 1 As shown, a galvanized plastic-sprayed malleable steel pipe fitting includes a malleable steel pipe fitting base, which is characterized in that: the surface of the malleable steel pipe fitting base has a galvanized layer and a plastic-sprayed layer in turn, the galvanized layer is the inner layer, and the plastic-sprayed layer It is the outer layer; the thickness of the galvanized layer is 60 μm; the thickness of the sprayed plastic layer is 100 um; the adhesion is ≤ grade 1; the impact resistance is ≥ 70 kg·cm; the sprayed plastic layer is an epoxy resin layer.

[0024] A method for preparing galvanized plastic-sprayed malleable steel pipe fittings, characterized in that it comprises the following steps:

[0025] A. Steps of shot blasting of malleable steel pipe fitting substrate 1: the shot blasting time of malleable steel pipe fitting substrate 1 is 30 minutes, so that the surface of malleable steel pipe fitting substrate 1 reaches the national standa...

Embodiment 2

[0041] Such as figure 1 As shown, a galvanized plastic-sprayed malleable steel pipe fitting includes a malleable steel pipe fitting base, which is characterized in that: the surface of the malleable steel pipe fitting base has a galvanized layer and a plastic-sprayed layer in turn, the galvanized layer is the inner layer, and the plastic-sprayed layer It is the outer layer; the thickness of the galvanized layer is 80 μm; the thickness of the sprayed plastic layer is 130 um; the adhesion is ≤ grade 1; the impact resistance is ≥ 70 kg·cm, and the sprayed plastic layer is a pure polyester layer.

[0042] A method for preparing galvanized plastic-sprayed malleable steel pipe fittings, characterized in that it comprises the following steps:

[0043] A. Steps of shot blasting of malleable steel pipe fitting substrate 1: the shot blasting time of malleable steel pipe fitting substrate 1 is 40 minutes, so that the surface of malleable steel pipe fitting substrate 1 reaches the nationa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com