Lubricating and cooling combined structure of engine piston and connecting rod group

A piston connecting rod, lubrication and cooling technology, applied in the direction of engine cooling, engine lubrication, engine components, etc., can solve the problems of scratched connecting rod small end bushing, insufficient piston cooling, low oil pressure, etc., to achieve lubrication And the effect of high cooling efficiency, simple design, high oil flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in conjunction with accompanying drawing and specific embodiment:

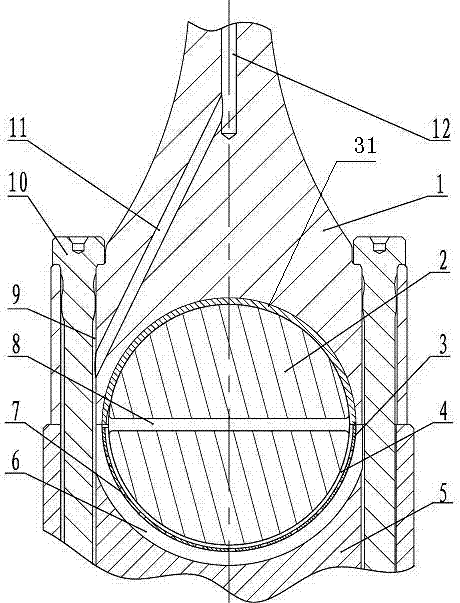

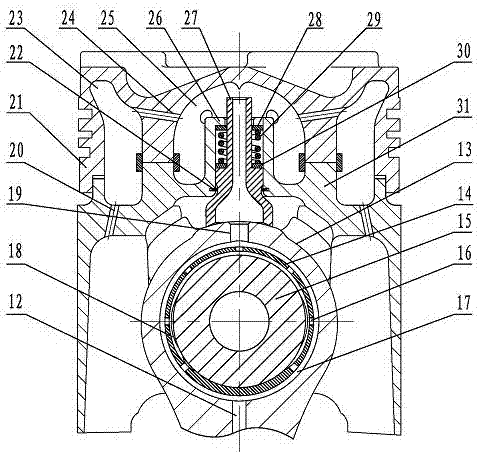

[0024] Such as figure 1 , figure 2Shown, a kind of lubricating and cooling combined structure of engine piston connecting rod group, piston connecting rod group includes piston, piston pin 15 and connecting rod; The connecting rod small end 13 of described connecting rod passes piston pin 15 and described Piston connection; a connecting rod small end bushing 14 is arranged between the piston pin 15 and the small end 13 of the connecting rod; the semicircular hole at the large end of the connecting rod shaft 1 and the semicircular hole of the connecting rod cover Two semicircular upper connecting rod bearing bushes 32 and lower connecting rod bearing bushes 3 are embedded respectively. The upper and lower connecting rod bearing bushes are installed on the connecting rod journal 2 of the crankshaft and are clearance-fitted with the connecting rod journal 2. The connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com