Production device and production method for double-component polyurethane adhesive

A two-component polyurethane and production device technology, applied in the field of polyurethane, can solve problems such as uneven stirring, poor temperature uniformity, and influence on output volume, and achieve the effects of reducing thermal conductivity, ensuring temperature uniformity, and improving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

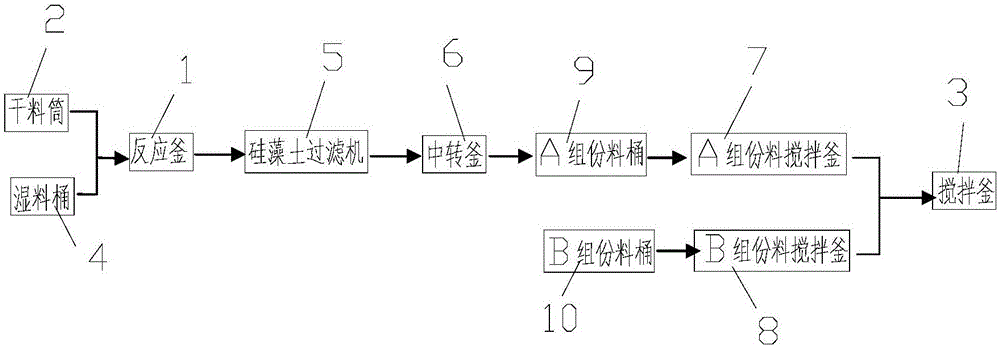

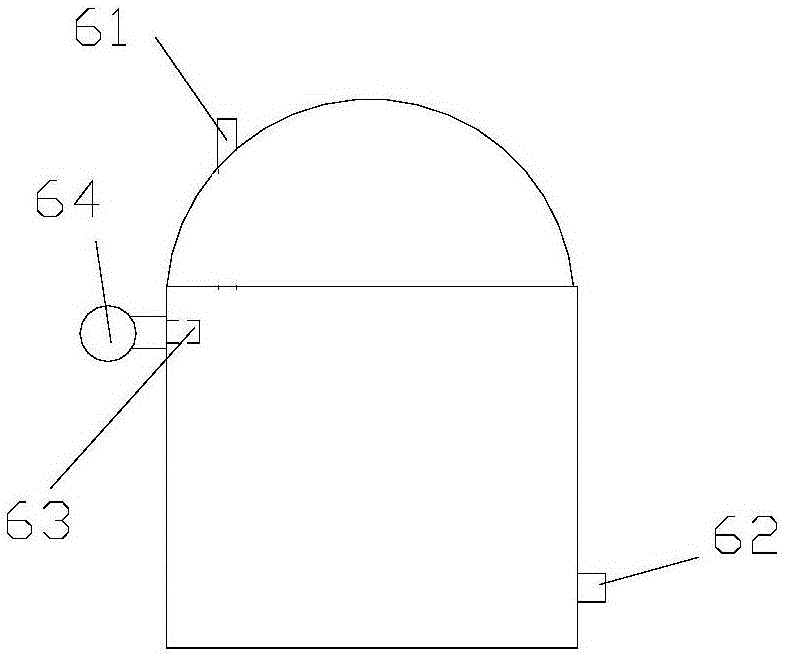

[0047] Such as Figure 1-4 As shown, the present invention discloses a production device of a two-component polyurethane adhesive, including a reaction kettle 1, a dry material tank 2, a stirring tank 3, a wet material tank 4, a diatomite filter 5, a transfer tank 6, a Component Stirring Tank 7, Component B Stirring Tank 8, Component A Tank 9, and Component B Tank 10.

[0048] The diatomite filter 5, component A material stirring tank 7, and B component material stirring tank 8 are all existing equipment.

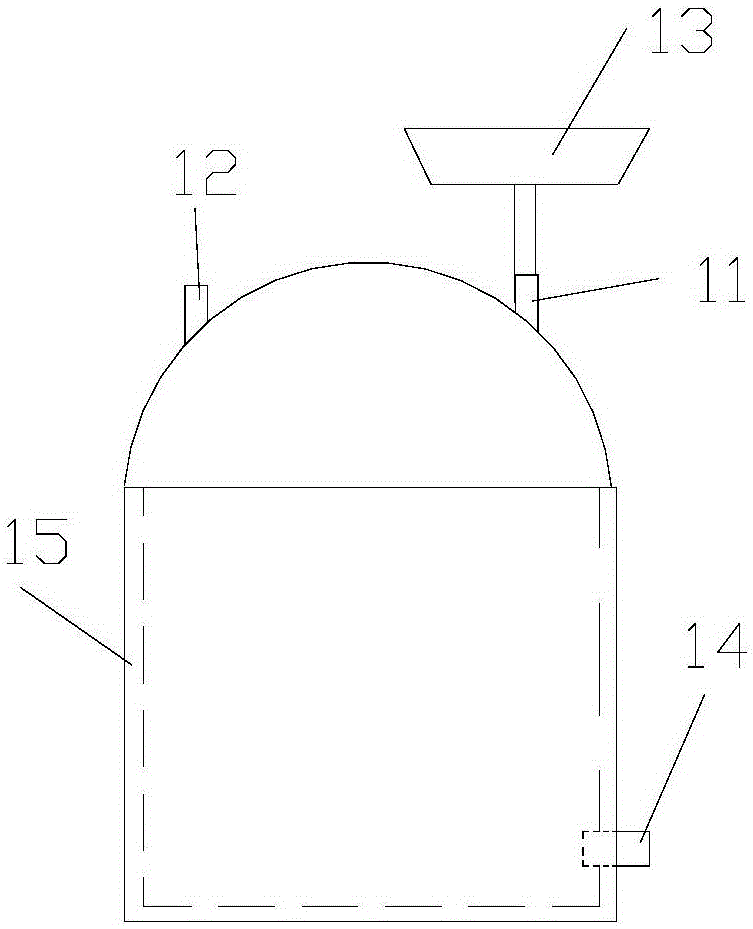

[0049] The lid of the reaction kettle 1 is provided with a dry material inlet 11, a wet material inlet 12 and a dry material funnel 13, and the bottom of the dry material funnel 13 communicates with the dry material inlet 11, and the reaction kettle 1 The lower end of the kettle body is provided with a reactant outlet 14; the raw materials in the dry material tank 2 are fed into the reaction kettle 1 through the dry material funnel 13, and the raw materials in the wet mate...

Embodiment 2

[0071] Such as figure 1 Shown, present embodiment discloses a kind of method of producing two-component polyurethane adhesive, described method comprises the steps:

[0072] (1) Put glycerin and diethylene glycol into the wet bucket 4, put phthalic anhydride and purified terephthalic acid into the dry bucket 2; Phthalic acid is added into the reaction kettle 1 in a mass ratio of 4:1:1:4, and the reaction is carried out at 220° C. and normal pressure;

[0073] (2) Feed the reactant obtained in step (1) into the diatomaceous earth filter 5, and filter to obtain polyester polyol;

[0074] (3) polyester polyol is fed in the described transfer kettle 6, and liquid storage is carried out;

[0075] (4) Mix the polyester polyol in the transfer tank 6 with silicone oil, water, and DMF in the component A material barrel 9 in a mass ratio of 16:1:1:2, and feed it into the Stir in the A component material stirring tank 7 to obtain the A component material;

[0076] (5) Mix Desmodur, p...

Embodiment 3

[0079] Such as figure 1 Shown, present embodiment discloses a kind of method of producing two-component polyurethane adhesive, described method comprises the steps:

[0080] (1) Put glycerin and diethylene glycol into the wet bucket 4, put phthalic anhydride and purified terephthalic acid into the dry bucket 2; Phthalic acid was added into the reactor 1 in a mass ratio of 42:12:8:38, and the reaction was carried out at 210° C. and normal pressure;

[0081] (2) feed the reactant obtained in step (1) into the diatomaceous earth filter 5, and filter to obtain polyester polyol;

[0082] (3) polyester polyol is fed in the described transfer kettle 6, and liquid storage is carried out;

[0083] (4) Mix the polyester polyol in the transfer tank 6 with silicone oil, water, and DMF in the component A material barrel 9 in a mass ratio of 82:7:3:8, and feed it into the Stir in the A component material stirring tank 7 to obtain the A component material;

[0084] (5) Mix Desmodur, para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com