Production process of a new type of anti-corrosion coating for water pipe elbows

An anti-corrosion coating and production process technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems that anti-corrosion coatings cannot meet long-term anti-corrosion needs, large contact area between sewage and elbows, waste of manpower and material resources, etc., to achieve outstanding acid resistance. , The effect of strong acid or alkali corrosion resistance, not easy to corrode and leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

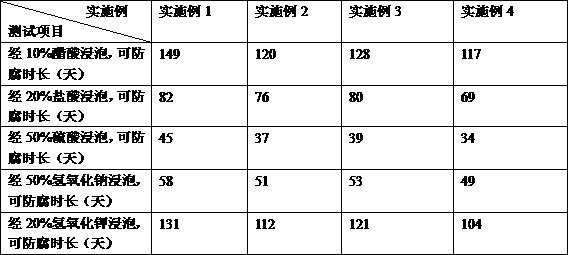

Examples

Embodiment 1

[0040] A new type of production process for anti-corrosion coatings for water pipe elbows, the production process is as follows:

[0041] (1) Organic material handling

[0042] ① Put 32 parts by mass of isocyanate into the reaction kettle, stir at a rate of 170r / min, and gradually add 19 parts by mass of amino resin to obtain a reaction mixture;

[0043] ② Stir the mixed reactants obtained in step (1) ① at a rate of 200r / min, control the reaction temperature at 72-76°C, and react for 3.5 hours to obtain a reaction polymer;

[0044] ③Stir at a rate of 300r / min, gradually add 8 parts by mass of biuret into the reactor, and mix it with the reaction polymer obtained in step (1)②. After adding the biuret, control the temperature to 48 Stir at -53°C for 50min at a rate of 150r / min to obtain an organic coating;

[0045] (2) Inorganic material handling

[0046] ① Grinding zinc oxide particles with 7 parts by mass into zinc oxide fine powder through a grinder;

[0047] 2. Gained zi...

Embodiment 2

[0055] A new type of production process for anti-corrosion coatings for water pipe elbows, the production process is as follows:

[0056] (1) Organic material handling

[0057] ① Put 33 parts by mass of isocyanate into the reaction kettle, stir at a rate of 180r / min, and gradually add 25 parts by mass of amino resin to obtain a reaction mixture;

[0058] ② Stir the mixed reactants obtained in step (1) ① at a rate of 140r / min, control the reaction temperature at 75-79°C, and react for 4.5 hours to obtain a reaction polymer;

[0059] ③Stir at a rate of 320r / min, gradually add 8 parts by mass of biuret into the reactor, and mix it with the reaction polymer obtained in step (1)②. After adding the biuret, control the temperature to 47 Stir at -50°C for 50min at a rate of 190r / min to obtain an organic coating;

[0060] (2) Inorganic material handling

[0061] ① Grinding zinc oxide particles with 6 parts by mass into zinc oxide fine powder through a grinder;

[0062] 2. Gained zi...

Embodiment 3

[0069] A new type of production process for anti-corrosion coatings for water pipe elbows, the production process is as follows:

[0070] (1) Organic material handling

[0071] ① Put 26 parts by mass of isocyanate into the reaction kettle, stir at a rate of 230r / min, and gradually add 32 parts by mass of amino resin to obtain a reaction mixture;

[0072] ② Stir the mixed reactants obtained in step (1) ① at a rate of 210r / min, control the reaction temperature at 73-76°C, and react for 3.5 hours to obtain a reaction polymer;

[0073] ③Stir at a rate of 320r / min, gradually add 7 parts by mass of biuret into the reactor, and mix it with the reaction polymer obtained in step (1)②. After adding the biuret, control the temperature to 43 Stir at -46°C for 45min at a rate of 260r / min to obtain an organic coating;

[0074] (2) Inorganic material handling

[0075] ① Grinding zinc oxide particles with 7 parts by mass into zinc oxide fine powder through a grinder;

[0076] 2. the zinc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com