Organic silicon-boron ceramic precursor as well as preparation method and application thereof

A ceramic precursor, organic technology, applied in the direction of silicon-organic compounds, etc., can solve the problem of heat resistance, tracking resistance, and deterioration of mechanical properties and processing properties of addition-type liquid silicone rubber that have not been found in silicone-boron ceramic precursors. , poor compatibility of silicone rubber, etc., to achieve the effect of facilitating large-scale production, improving heat resistance and arc ablation resistance, and not easy to hydrolyze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

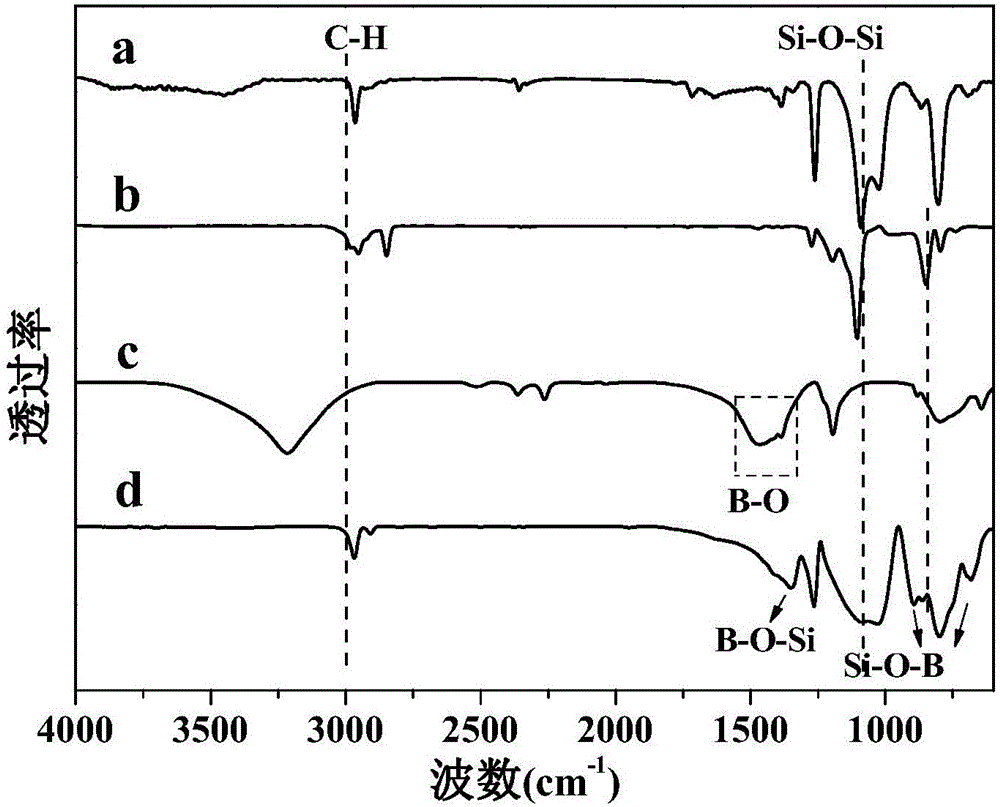

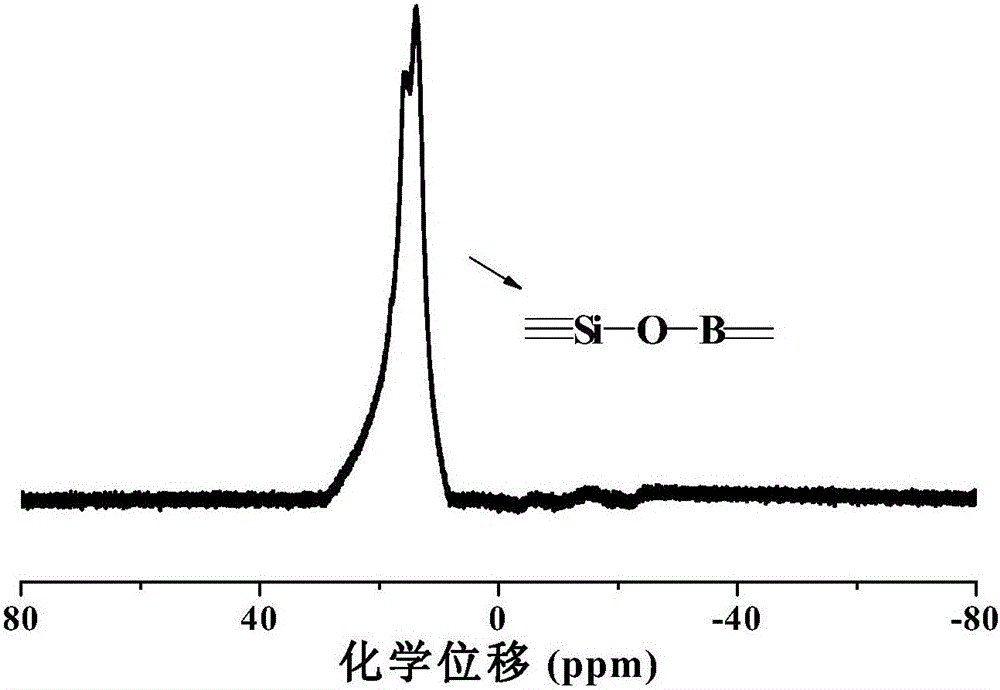

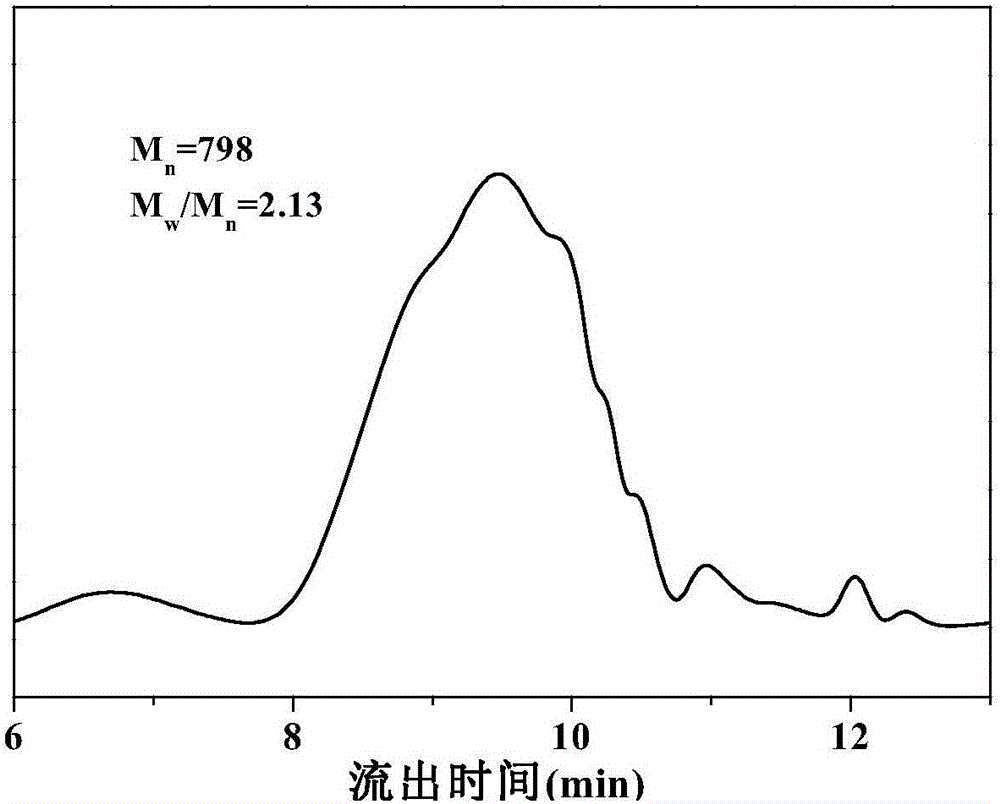

Embodiment 1

[0043] Add 6.7g of octamethylcyclotetrasiloxane (D4), 3.1g of methyltrimethoxysilane (MTMS) and 2.1g of boric acid (BA) into a four-necked 250mL flask equipped with mechanical stirring and a serpentine reflux tube, Then measure 10 mL of diethylene glycol dimethyl ether and add 0.1 g of concentrated sulfuric acid dropwise, pour it into a flask, raise the temperature to 30°C and stir for 15 minutes, then raise the temperature to 80°C, keep the temperature for 2 hours, then raise the temperature to 150°C, and react for 2 hours. Finally, the reaction system was cooled to normal temperature until excess boric acid was precipitated. After the reaction, the reaction system was transferred to a centrifuge tube, centrifuged at a rotation speed of 10,000 r / min for 10 min, and the liquid was separated. Subsequently, distilled under reduced pressure at 100°C until there was no droplet in the recovery bottle to obtain a gel-like product, cooled to 50°C, then added 40 mL of n-hexane to mech...

Embodiment 2

[0050] According to the method and process in Example 1, the difference is that the amount of BA is increased to 3.5g to prepare Si-BOCP-2 and apply it to the addition-type liquid silicone rubber. Compared with Comparative Example 1, Si-BOCP-2 improved the thermal stability of silicone rubber, and compared with Example 1, the initial decomposition temperature increased from 433.7°C to 438.4°C, and the heat-resistant modification effect was slightly better than that of Si-BOCP-2. For BOCP-1, the initial tracking time is extended to 3130s.

Embodiment 3

[0052] According to the method and process in Example 2, the amount of D4 and MTMS used remained unchanged, and the amount of BA was increased to 4.9g to prepare Si-BOCP-3, which was applied to the addition-type liquid silicone rubber. It can be seen from Table 2 that with the further increase in the amount of boric acid, the heat resistance modification effect of Si-BOCP-3 decreased compared with Si-BOCP-2, but compared with the comparative example, the addition of Si-BOCP- The heat resistance of the silicone rubber of 3 is still higher than that of the blank silicone rubber, in which the initial thermal decomposition temperature increases from 406.6°C to 427.5°C, and the initial tracking time also increases from 960s to 3250s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com