Aluminum Bronze Drip Boriding Process

A technology of aluminum bronze and boronizing, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of high labor intensity, high cost of penetrating agent, poor working conditions, etc., and achieve low labor intensity, The effect of convenient operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

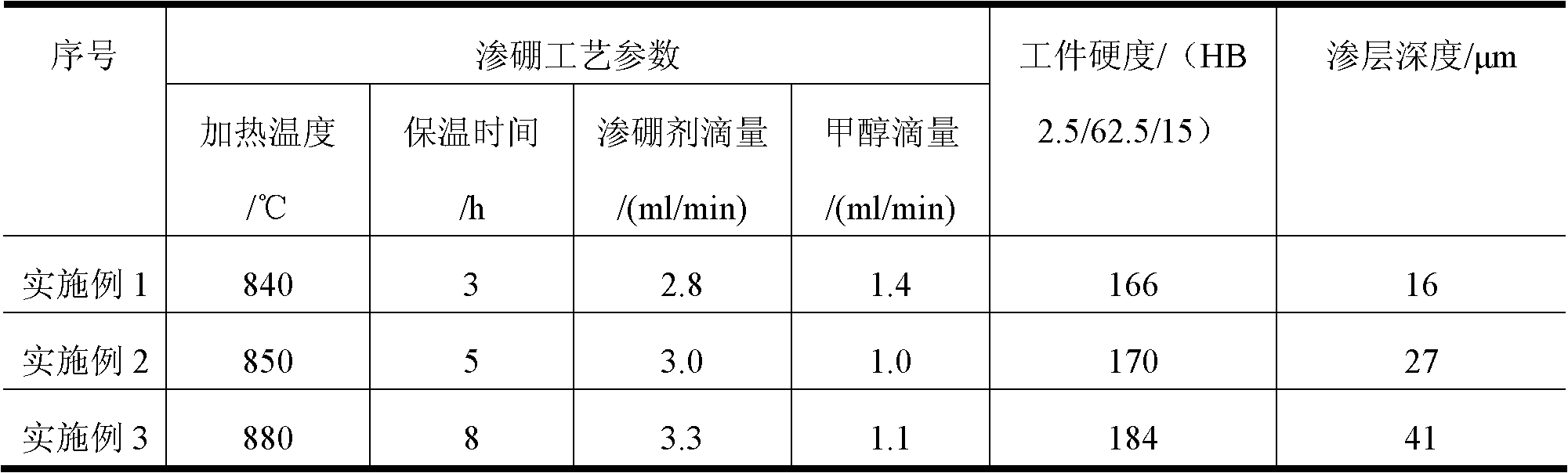

Embodiment 1

[0040] Example 1 The weight ratio of rare earth chloride to trimethyl borate in the boronizing agent is 1:20; the volume ratio of methanol to trimethyl borate is 1:1.

Embodiment 2

[0041] Example 2 The weight ratio of rare earth chloride to trimethyl borate in the boronizing agent is 1:23; the volume ratio of methanol to trimethyl borate is 1:1.2.

Embodiment 3

[0042] Example 3 The weight ratio of rare earth chloride to trimethyl borate in the boronizing agent is 1:30; the volume ratio of methanol to trimethyl borate is 1:1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com