Iron-based flux-cored wire and preparation method thereof

A technology of iron-based flux-cored and flux-cored wire, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of unfavorable continuous welding, low welding efficiency, poor welding processability, etc., and achieve reduction of welding heat input, The effect of high welding current density and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

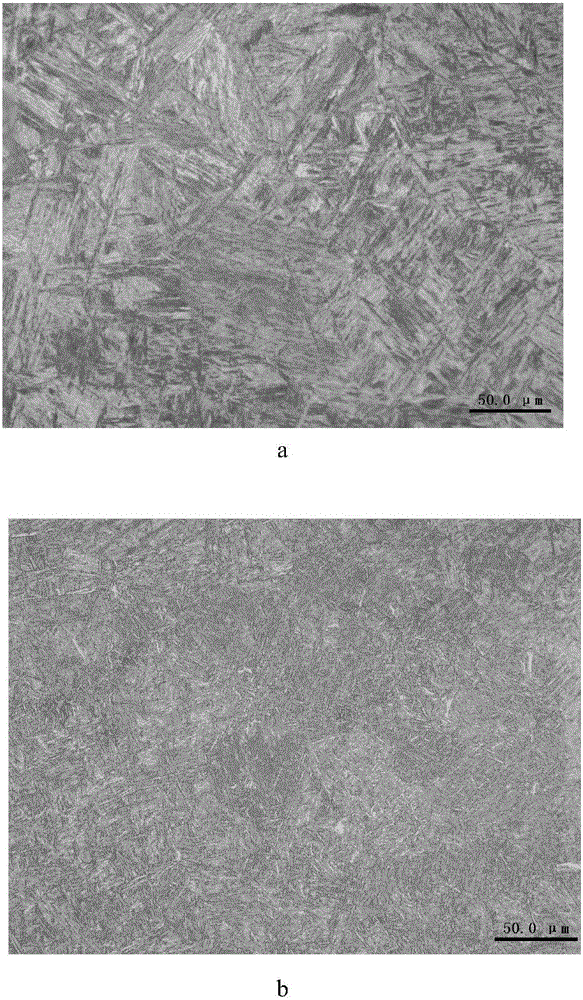

[0030] This embodiment is an iron-based flux-cored welding wire and a preparation method thereof.

[0031] The iron-based flux-cored wire consists of 2.5% to 5% of ferrosilicon, 5% to 7% of manganese powder, 0.8% to 2% of chromium powder, 5% to 15% of nickel powder, 0.5% to 1.2% of Composed of molybdenum powder and 69.8% to 86.2% iron powder. In the present embodiment, the content of ferrosilicon is 5%, the content of manganese powder is 7%, the content of chromium powder is 2%, the content of nickel powder is 15%, the content of molybdenum powder is 1.2%, the content of iron powder is 69.8%. The stated percentages are all mass percentages.

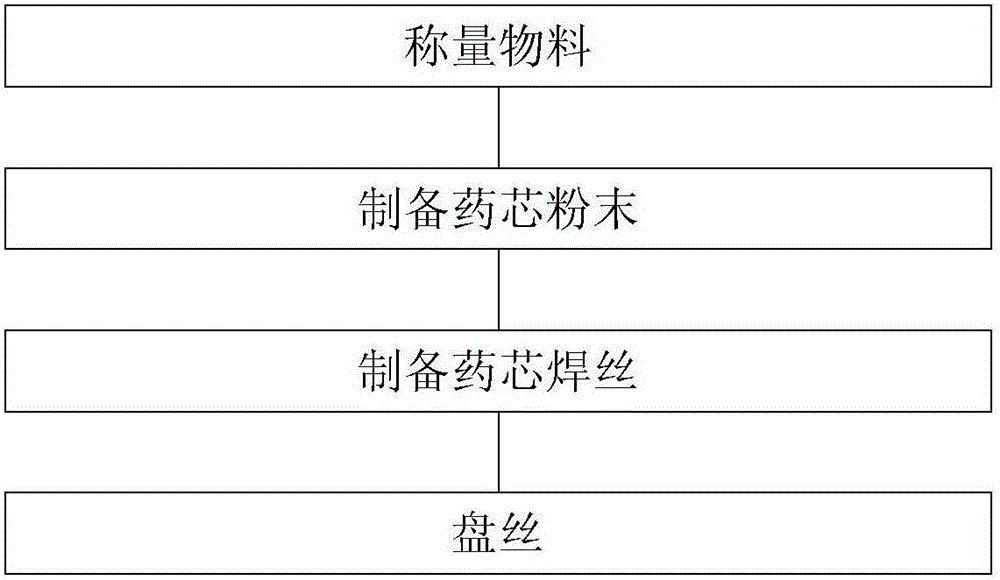

[0032] The specific process for preparing the iron-based flux-cored wire proposed in this embodiment is:

[0033] Step 1, weigh the material. Weigh 5% of ferrosilicon, 7% of manganese powder, 2% of chromium powder, 15% of nickel powder, 1.2% of molybdenum powder and 69.8% of iron powder in proportion, and the percentages are mass perc...

Embodiment 2

[0039] The iron-based flux-cored welding wire proposed in this embodiment is composed of 3% ferrosilicon, 6% manganese powder, 1.5% chromium powder, 10% nickel powder, 1% molybdenum powder and 78.5% iron powder. The percentages are mass percentages.

[0040]The specific process for preparing the iron-based flux-cored wire proposed in this embodiment is:

[0041] Step 1, weigh the material. Weigh 3% of ferrosilicon, 6% of manganese powder, 1.5% of chromium powder, 10% of nickel powder, 1% of molybdenum powder and 78.5% of iron powder, and the percentages are mass percentages.

[0042] Step 2, preparing drug core powder. After mixing the weighed powder evenly, place it in a drying oven for drying at a temperature of 250°C and a drying time of 2.5 hours to ensure that all the free water and bound water in the powder are volatilized to obtain a drug core powder.

[0043] Step 3, preparing flux-cored welding wire. The low-carbon steel strip is placed on the unloading machine o...

Embodiment 3

[0047] The iron-based flux-cored welding wire proposed in this embodiment is composed of 5% ferrosilicon, 7% manganese powder, 2% chromium powder, 11% nickel powder, 1.2% molybdenum powder and 73.5% iron powder. The percentages are mass percentages.

[0048] The specific process for preparing the iron-based flux-cored wire proposed in this embodiment is:

[0049] Step 1, weigh the material. Weigh 5% of ferrosilicon, 7% of manganese powder, 2% of chromium powder, 11% of nickel powder, 1.2% of molybdenum powder and 73.5% of iron powder, and the percentages are mass percentages.

[0050] Step 2, preparing drug core powder. After mixing the weighed powder evenly, place it in a drying oven for drying at a temperature of 300°C and a drying time of 2.2 hours to ensure that all the free water and bound water in the powder are volatilized to obtain a drug core powder.

[0051] Step 3, preparing flux-cored welding wire. The low-carbon steel strip is placed on the unloading machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com