Preparation method and application of sodium stearyl lactate

A technology of sodium stearoyl lactylate and stearic acid, which is applied in the chemical industry, can solve problems that have not yet been discovered, and achieve the effects of fine and smooth taste, short reaction cycle and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

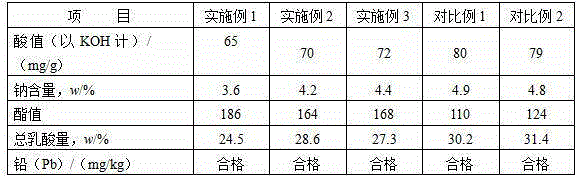

Examples

Embodiment 1

[0022] Embodiment 1, the preparation method of sodium stearoyl lactylate of the present invention

[0023] Add 400mol lactic acid into water, the weight ratio of lactic acid to water is 1:1.5, stir evenly, then add 133mol sodium carbonate, stir at 60°C for 1h, then add 200mol stearic acid and 18mol polyethylene glycol-400, at temperature React at 165°C for 2 hours under a vacuum of 0.08MPa. After the reaction is completed, the product is recrystallized with absolute ethanol, and after vacuum drying, sodium stearoyl lactylate is obtained. The obtained sodium stearoyl lactylate is a white brittle solid.

Embodiment 2

[0024] Embodiment 2, the preparation method of sodium stearoyl lactylate of the present invention

[0025] Add 250mol lactic acid into water, the weight ratio of lactic acid to water is 1:1, stir evenly, then add 100mol sodium carbonate, stir at 55°C for 1.5h, then add 200mol stearic acid and 20mol polyethylene glycol-400, in React at a temperature of 160°C and a vacuum of 0.09 MPa for 3 hours. After the reaction is completed, the material is discharged. The product is recrystallized with absolute ethanol and dried in vacuum to obtain sodium stearoyl lactylate. The obtained sodium stearoyl lactylate is a light yellow brittle solid.

Embodiment 3

[0026] Embodiment 3, the preparation method of sodium stearoyl lactylate of the present invention

[0027] Add 400mol lactic acid into water, the weight ratio of lactic acid to water is 1:2, stir evenly, then add 100mol sodium carbonate, stir at 65°C for 1h, then add 100mol stearic acid and 8mol polyethylene glycol-400, at temperature React at 180°C for 2.5 hours under a vacuum of 0.07 MPa. After the reaction is complete, the material is discharged. The product is recrystallized with absolute ethanol and dried in vacuum to obtain sodium stearoyl lactylate. The obtained sodium stearoyl lactylate is a light yellow brittle solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com