Organic functionalized graphene material and preparation method and application thereof

A graphene and fossil technology, applied in the field of organic functionalized graphene materials, can solve the problems of low capacity and poor conductivity of graphene materials, and achieve the effects of high charge and discharge capacity, improved conductivity, and excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a method for preparing an organic functionalized graphene material. Graphene oxide is placed in deionized water and stirred for 30 minutes, and the graphene oxide is dispersed evenly after ultrasonication for 30 minutes. Tetrahydroxybenzoquinone and tetrahydroxybenzoquinone are added. The mass ratio of quinone to graphene oxide was 1:1, and the mixture was dried at 85° C. after continuous stirring for 12 hours to obtain a tetrahydroxybenzoquinone functionalized graphene material.

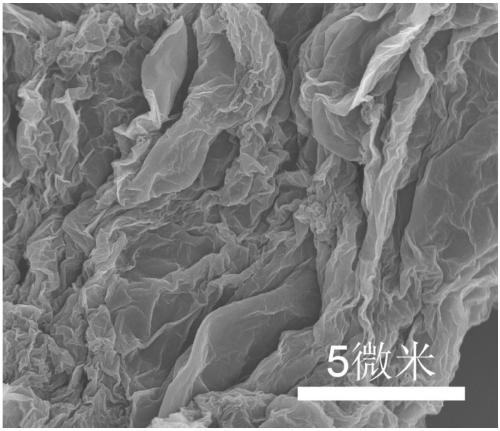

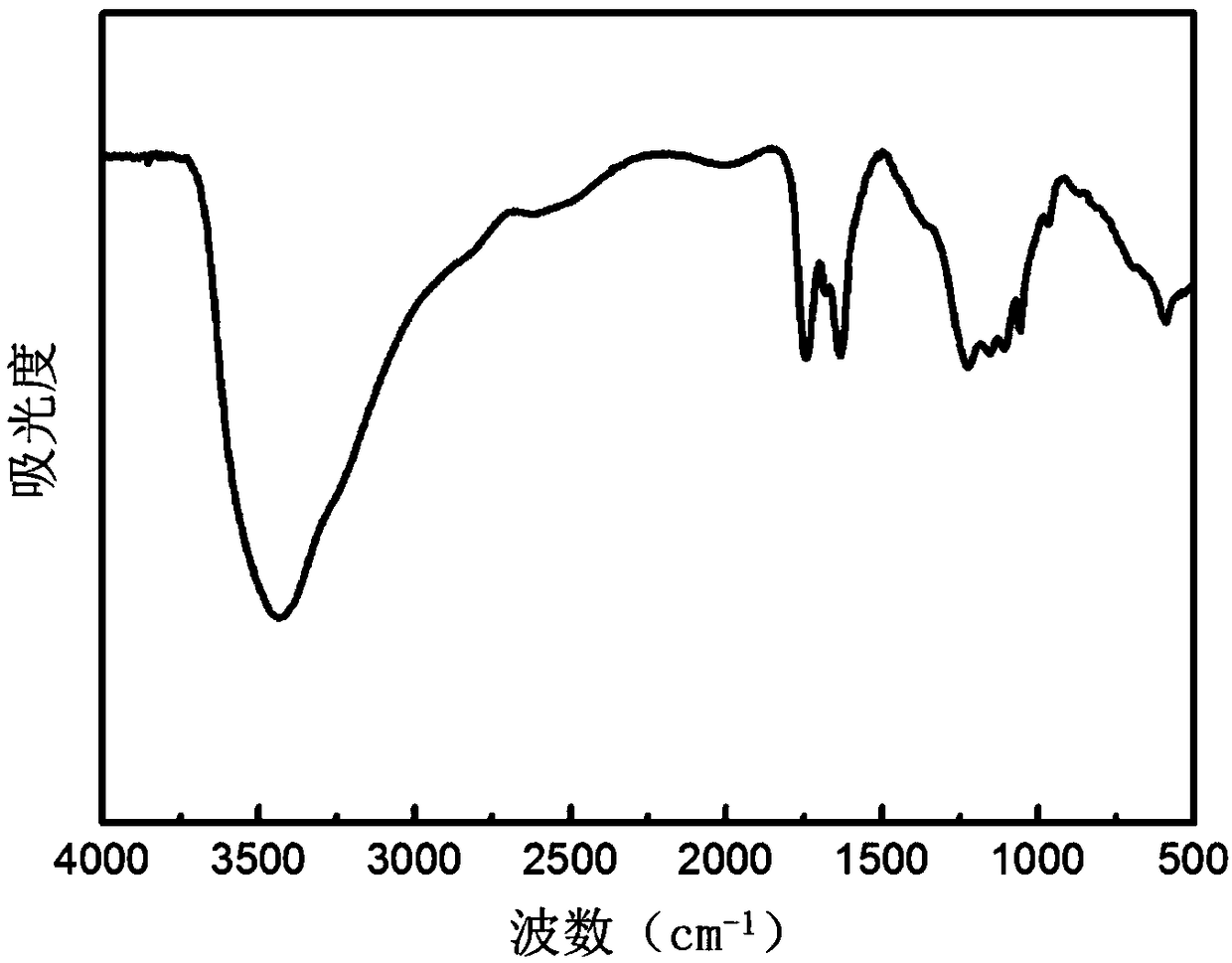

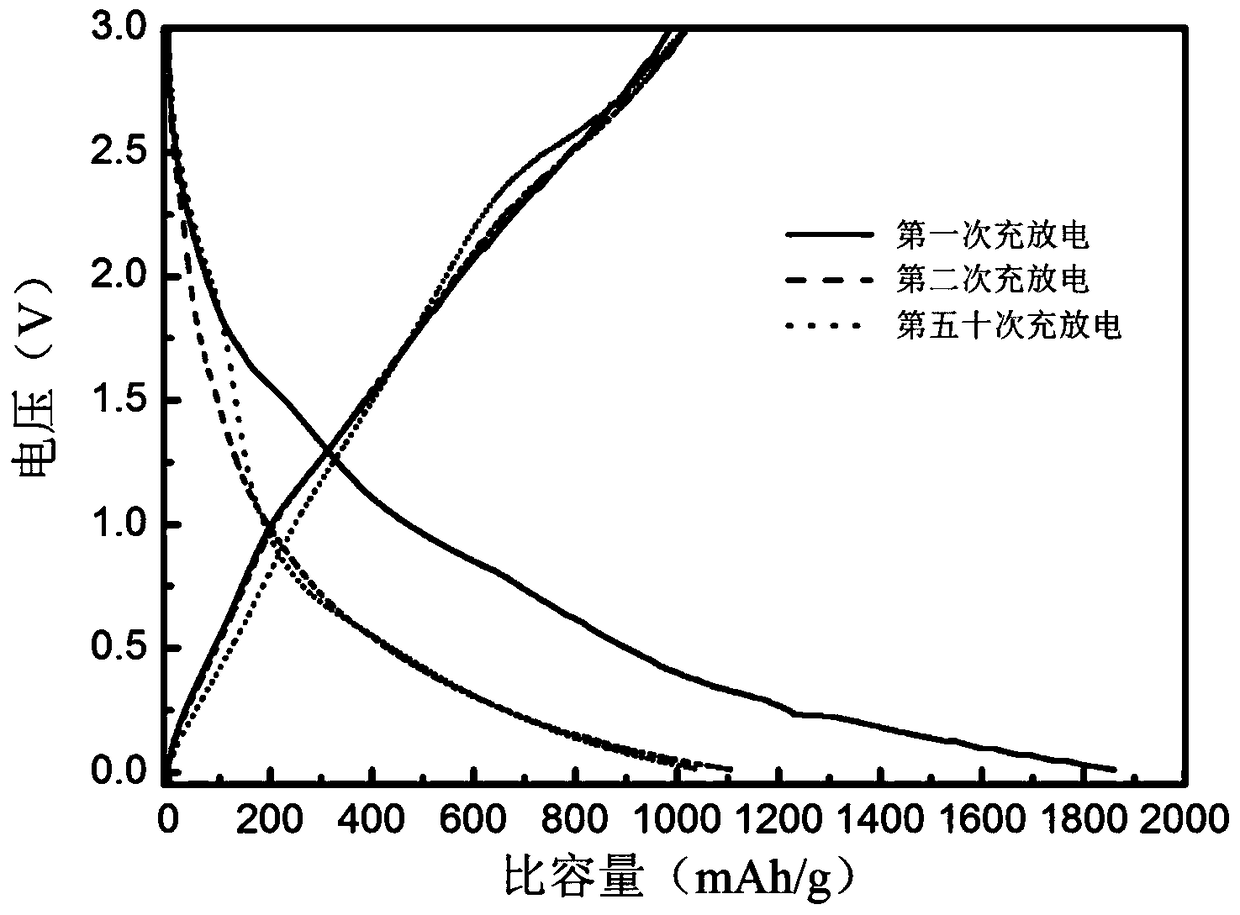

[0029] The SEM photo of the tetrahydroxybenzoquinone functionalized graphene material prepared by the present embodiment is as follows figure 1 As shown, there are abundant wrinkles on the surface of the visible sample, indicating that tetrahydroxybenzoquinone has been attached to the surface of graphene oxide. figure 2 It is the FT-IR test spectrum of the sample, in the figure 1740cm -1 An obvious sharp peak appears at , which is the characteristic peak of the este...

Embodiment 2

[0032] This embodiment provides a method for preparing an organic functionalized graphene material. Graphene oxide is placed in deionized water and stirred for 30 minutes, and the graphene oxide is dispersed evenly after ultrasonication for 30 minutes. Tetrahydroxybenzoquinone and tetrahydroxybenzoquinone are added. The mass ratio of quinone to graphene oxide was 1:3, and the mixture was dried at 100° C. after continuous stirring for 6 hours to obtain a tetrahydroxybenzoquinone functionalized graphene material.

Embodiment 3

[0034] This embodiment provides a method for preparing an organic functionalized graphene material. Graphene oxide is placed in deionized water and stirred for 30 minutes, and the graphene oxide is dispersed evenly after ultrasonication for 30 minutes. Tetrahydroxybenzoquinone and tetrahydroxybenzoquinone are added. The mass ratio of quinone to graphene oxide was 3:1, and the mixture was dried at 70° C. after continuous stirring for 36 hours to obtain a tetrahydroxybenzoquinone functionalized graphene material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com