Treatment method of arsenium-containing polluted acid wastewater generated by smelting flue gas

A technology of polluted acid wastewater and smelting flue gas, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high investment, complicated process and waste of resources, etc. The effect of good treatment effect, simple operation and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

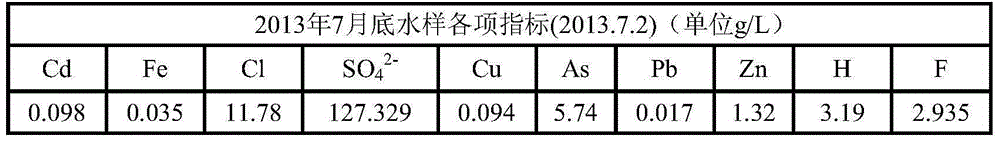

[0015] Embodiment 1: The composition of a certain smeltery sewage acid sample liquid is shown in Table 1:

[0016] Table 1 Water sample components

[0017]

[0018] Take 1L of this polluted acid for pretreatment to remove sulfate radicals, add 144.2g of anhydrous calcium chloride, stir at a speed of 600r / min, and react for 20min, while continuing to stir, add flocculant PAM2. min, stirring at a slow speed of 30r / min for 10min, standing for 20min, and then performing solid-liquid separation; the filter residue is mainly calcium sulfate, the arsenic content is less than 0.1%, which is not hazardous waste, and the removal rate of sulfate radical is 65.50%; the filtrate enters the pre-neutralization , slowly add lime to neutralize to pH = 0.5, stir at a speed of 600r / min, and react for 10min. While continuing to stir, add flocculant PAM1.5mg, stir at a medium speed of 120r / min for 4.5min, and stir at a slow speed of 30r / min for 10min. Stand still for 20 minutes, the filter res...

Embodiment 2

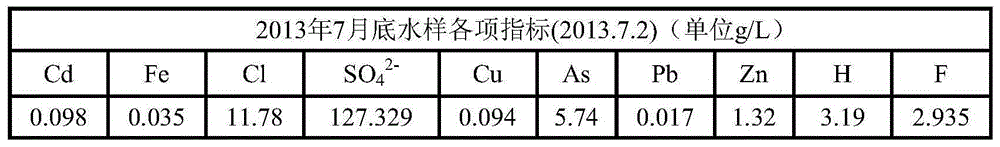

[0019] Embodiment 2: The composition of a certain smelter's sewage acid sample liquid is shown in Table 2:

[0020] Table 2 Water sample components

[0021]

[0022]Take 1L of this polluted acid for pretreatment to remove sulfate radicals, add the filtrate after neutralizing and removing arsenic for three times in Example 1, stir at a speed of 600r / min, and react for 40min, while continuing to stir, add 0.6mg of flocculant PAM at a medium speed of 120r / min stirring for 4.5min, slow speed 30r / min stirring for 10min, standing for 20min, and then solid-liquid separation; filter residue is mainly calcium sulfate, arsenic content is less than 0.1%, does not belong to hazardous waste, sulfate removal rate is 66.31%; filtrate Enter pre-neutralization, slowly add lime to neutralize to pH = 1, stirring speed 600r / min, time 10min to react, continue stirring while adding flocculant PAM2.0mg, medium speed 120r / min stirring 4.5min, slow speed 30r / min Stir for 10 minutes, let it stand ...

Embodiment 3

[0023] Embodiment 3: The composition of a certain smelter's sewage acid sample liquid is shown in Table 3:

[0024] Table 3 Water sample components

[0025]

[0026] Take 1L of this polluted acid for pretreatment to remove sulfate radicals, add 201.9g of anhydrous calcium chloride, stir at a speed of 600r / min, and react for 60min, while continuing to stir, add flocculant PAM1. min, stirring at a slow speed of 30r / min for 10min, standing for 20min, and then performing solid-liquid separation; the filter residue is mainly calcium sulfate, the arsenic content is less than 0.1%, which is not hazardous waste, and the removal rate of sulfate radical is 78.23%; the filtrate enters the pre-neutralization , Slowly add lime to neutralize to pH = 1, stir at a speed of 600r / min, and react for 30min. While continuing to stir, add flocculant PAM0.6mg, stir at a medium speed of 120r / min for 4.5min, and stir at a slow speed of 30r / min for 10min. Stand still for 20 minutes, the filter resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com