Synthetic method of colorful TiO2 microsphere and application of colorful TiO2 microsphere

A synthesis method and technology of microspheres, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

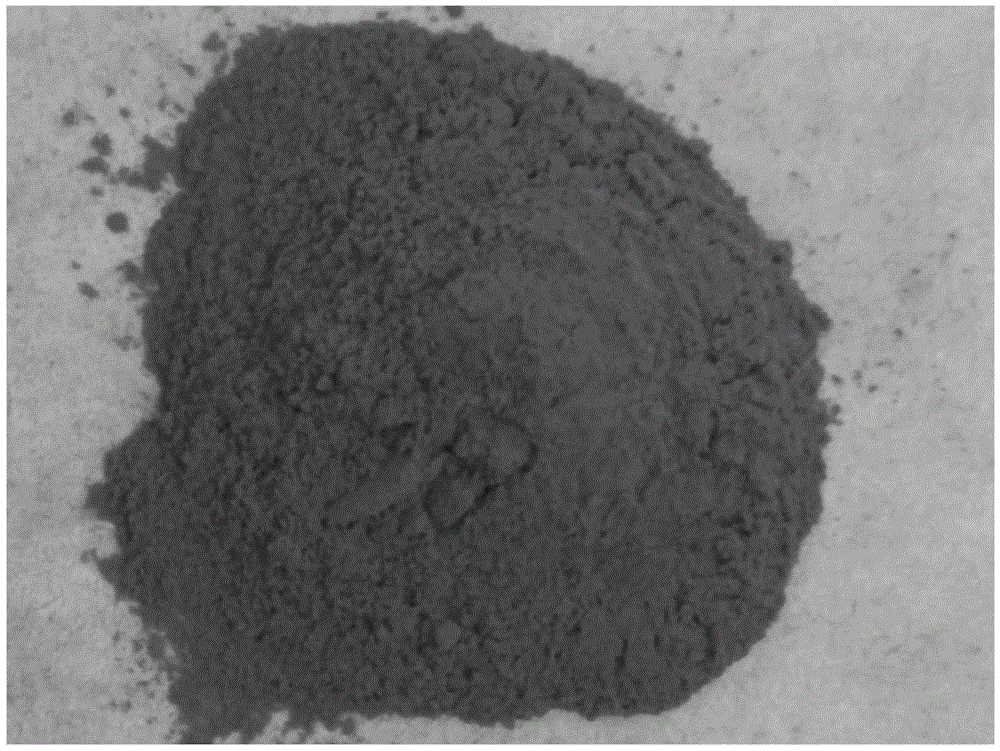

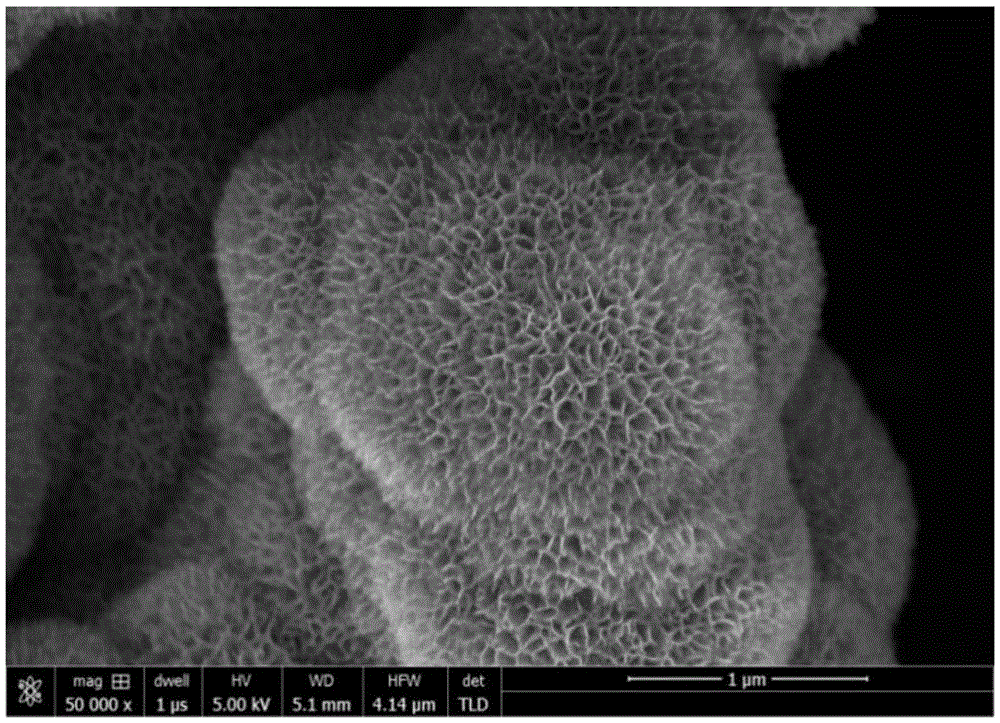

[0031] Mix acetylacetone and isopropanol at a volume ratio of 1:4 to form a mixed solvent, add 1ml of ethylenediamine, stir evenly, add 2ml of tetra-n-butyl titanate, then fully stir and transfer the mixed solution to the reaction kettle, React at 200°C for 16 hours. After natural cooling, red TiO was obtained by centrifugation, washing and drying. 2 Microspheres ( figure 1 ), microspheres composed of nanosheets with a diameter of ~1250nm ( figure 2 ).

Embodiment 2

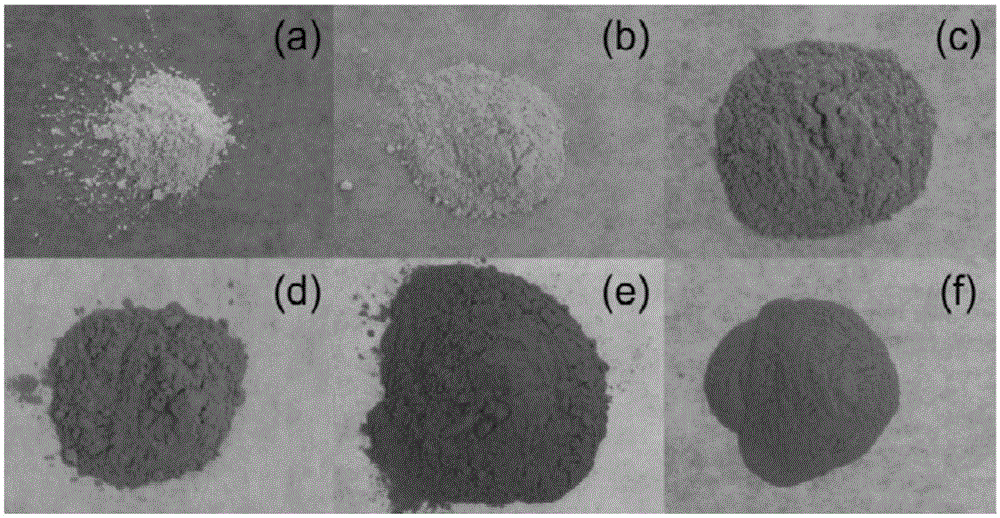

[0033] Mix acetylacetone and isopropanol at a volume ratio of 1:1 to form a mixed solvent, add 0.05, 0.10, 0.25, 0.50, 1.0 and 2.0ml of ethylenediamine, stir well, add 4ml of tetra-n-butyl titanate, and then fully The mixed solution was transferred to a reaction kettle with stirring, and reacted at 200° C. for 16 hours. After natural cooling, centrifuged, washed and dried colorful TiO 2 Microspheres ( image 3 ).

Embodiment 3

[0035] Due to the high content of dimethyl blue in the dye wastewater, it is easy to cause environmental pollution, so it was selected as the photocatalytic activity of the simulated pollutant under the irradiation of ultraviolet light. The resulting red TiO 2 Microspheres are used in photodegradation experiments to obtain absorption at different times and at different wavelengths ( Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com