A dry cleaning sterilizer and method thereof

A technology for sterilizers and dry cleaners, applied in packaging sterilization, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as wasting water resources, and achieve the effects of avoiding corrosion, short sterilization time, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

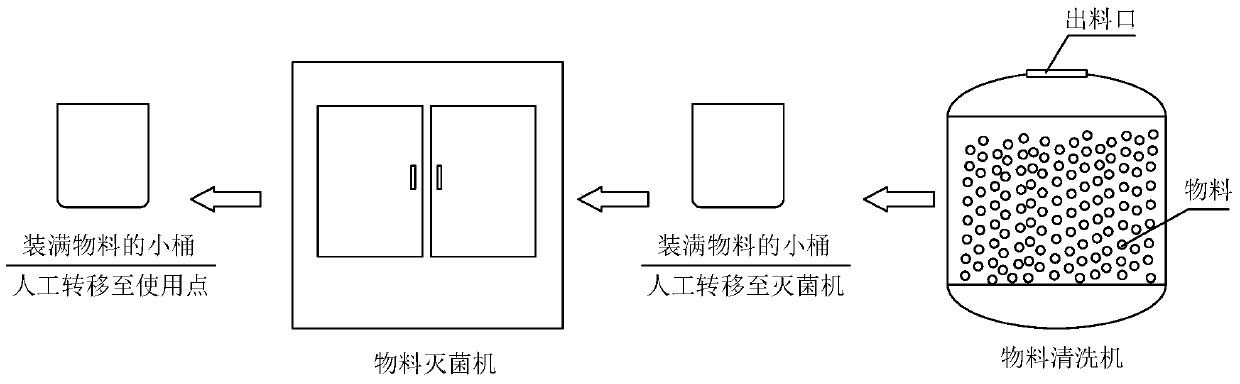

Problems solved by technology

Method used

Image

Examples

Embodiment

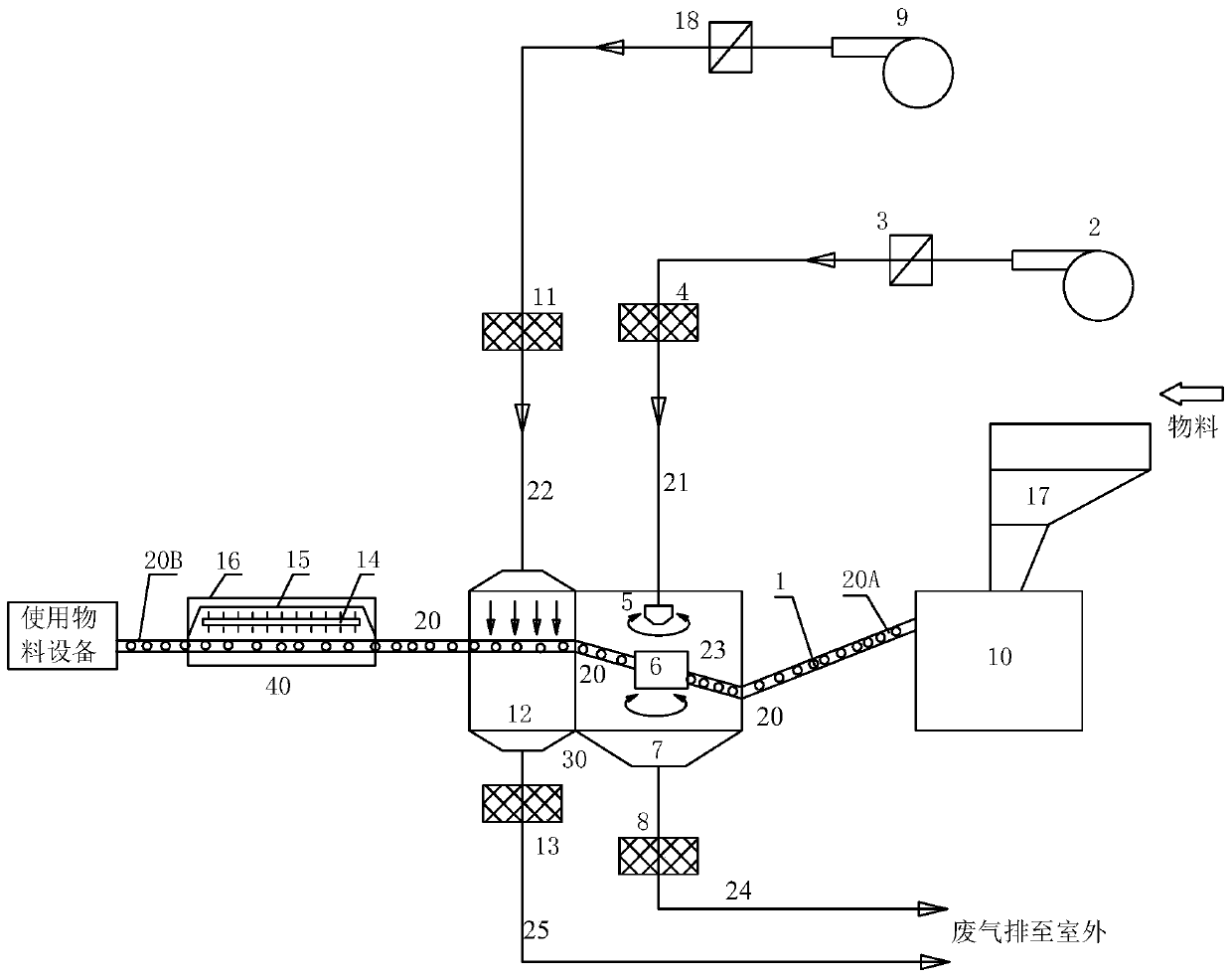

[0031] Embodiment: Utilize the dry-cleaning sterilization machine of the present invention to dry-clean and sterilize the aluminum caps of medicine vials. Among them, the pulse laser generator adopts a single lamp head, the pulse light emission time is controlled at 0.5ms, and the pulse frequency is controlled at 2 times / s.

[0032] The aluminum caps that need to be dry-cleaned and sterilized are put into the hopper 17, and the hopper 17 sends the aluminum caps to the sorting mechanism 10, and the sorting mechanism 10 completes the sorting of the aluminum caps, and inputs them into the conveyor belt 20. The conveyor belt 20 sends the aluminum cover to the dry cleaning machine 23, and the high-pressure hot air filtered to the A-level standard is sent to the air nozzle 5 through the first air supply pipeline 21, and the high-pressure gas ejected from the air nozzle 5 effectively cleans each surface of the aluminum cover Purge to blow off the dirt, particles, dust, etc. attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com