PBSE-based thermoelectric material compounded with Sr and Na and its preparation method

A technology of composite materials and thermoelectric materials, which is applied in the field of thermoelectric device material preparation, can solve problems such as low conversion efficiency, low conversion efficiency of thermoelectric materials, and restrictions on the application of thermoelectric devices, and achieve reduced thermal conductivity, short sintering time, and improved thermoelectric performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention are described in detail as follows:

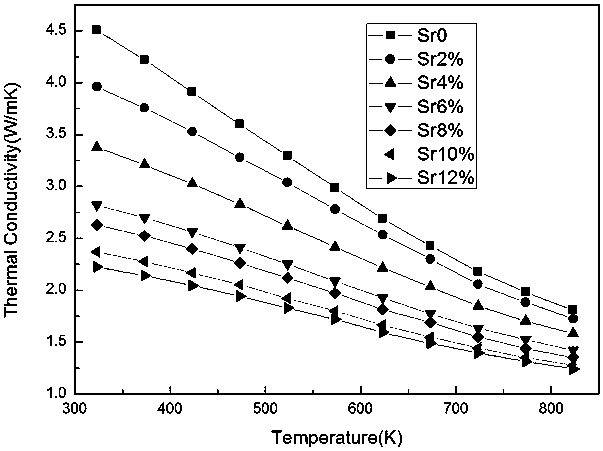

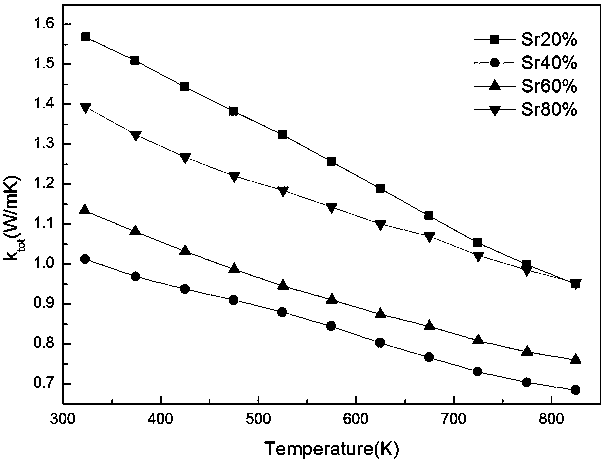

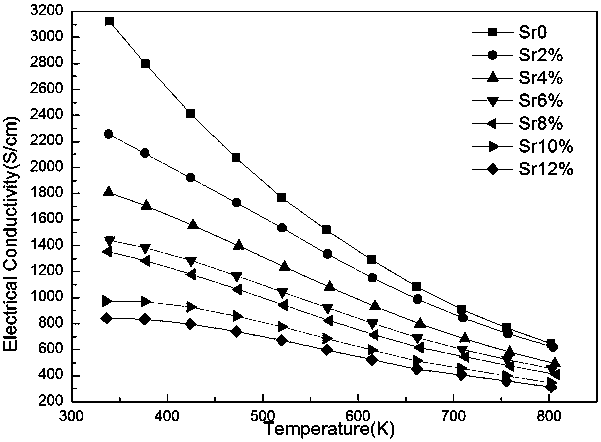

[0028] In this example, see Figure 1 to Figure 10 , a preparation method of a PbSe-based thermoelectric material doped with Sr and Na, comprising the steps of:

[0029] a. In the glove box according to the composite material composition Pb 0.88 Sr 0.10 Na 0.02 The molar component ratio of the stoichiometric ratio of Se weighed 5.3873g, 0.2595g, 0.15g and 2.3383g of the elemental materials of Sr, Na, Pb and Se respectively, and then weighed the elemental materials of Sr, Na, Pb and Se After the materials are evenly mixed, put them into a graphite crucible, seal the graphite crucible into a quartz tube with a propane flame, then put the vacuum-sealed graphite crucible into a well furnace, and then mix the Sr, Na, Pb and Se in the graphite crucible Material heat treatment smelting and calcination, first heat up at 5°C / min to the melting temperature of 1050°C for 24 hours, then cool do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com