Method for carrying out surface modification on polyether-ether-ketone material and modified polyether-ether-ketone material

A technology of polyether ether ketone and surface modification, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., to achieve the effect of improving osseointegration, simple and easy method, and promoting osteogenic differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

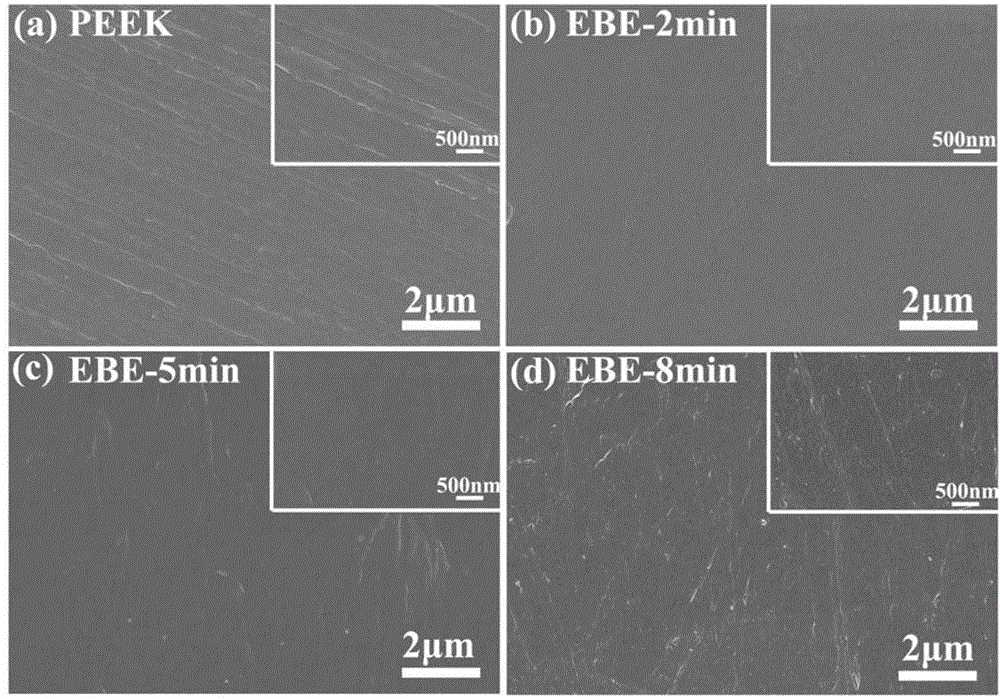

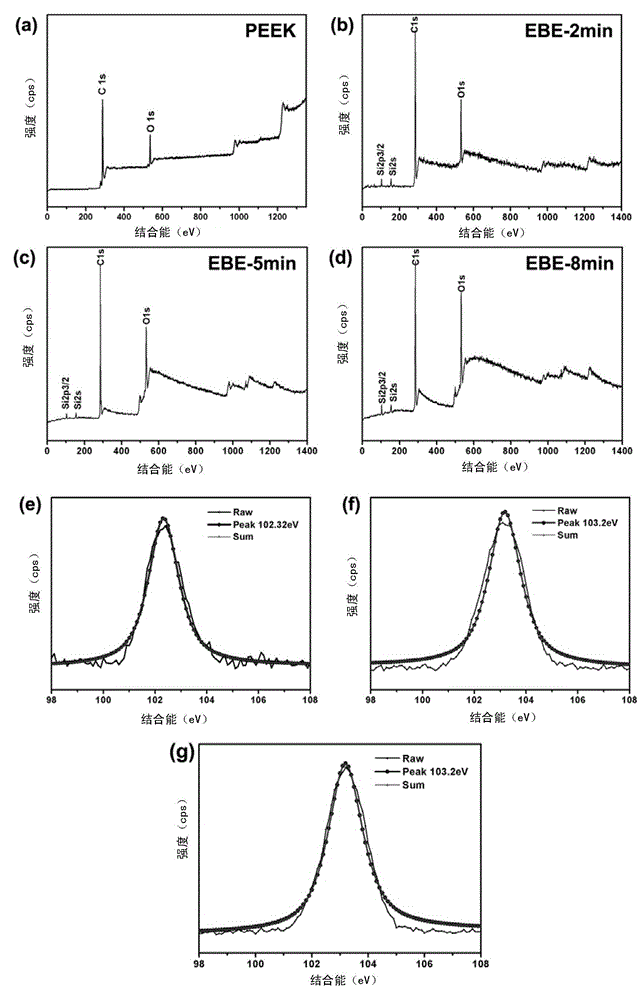

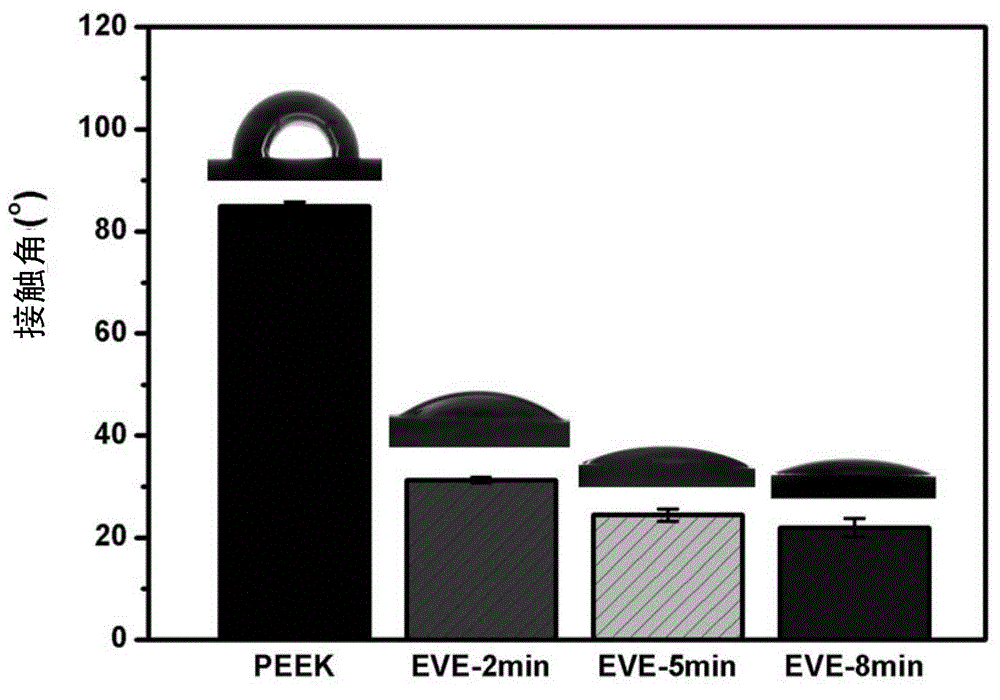

[0036] After polishing, the 10mm×10mm×1mm polyether ether ketone is cleaned by ultrasonic cleaning with acetone and deionized water in sequence, each time for 30 minutes, after cleaning, it is dried in an oven at 80°C and stored properly. Using electron beam evaporation technology, calcium silicate is used as the evaporation target material, and polyetheretherketone material is subjected to electron beam evaporation. The specific process parameters are shown in Table 1, and the obtained sample number is EBE-2min;

[0037] Table 1 Electron beam evaporation parameters:

[0038] Electron beam excitation voltage (kV)

8.5

electron beam current

1.6A

Evaporation time(min)

2

Background vacuum (Pa)

5×10 -3

[0039] ;

[0040] The silicon content on the surface of the modified polyetheretherketone material was 4.0%.

Embodiment 2

[0042] After polishing, the 10mm×10mm×1mm polyetheretherketone is ultrasonically cleaned with acetone and deionized water, each time for 30 minutes, and then dried in an oven at 80°C and stored properly. Using electron beam evaporation technology, using calcium silicate as the evaporation target material, the polyetheretherketone material is subjected to electron beam evaporation. The specific process parameters are shown in Table 2, and the obtained sample number is EBE-5min;

[0043] Table 2 E-beam evaporation parameters:

[0044] Electron beam excitation voltage (kV)

8.5

electron beam current

1.6A

Evaporation time(min)

5

Background vacuum (Pa)

5×10 -3

[0045] ;

[0046] The silicon content on the surface of the modified polyetheretherketone material is 5.0%.

Embodiment 3

[0048] After polishing, the 10mm×10mm×1mm polyether ether ketone is cleaned by ultrasonic cleaning with acetone and deionized water in sequence, each time for 30 minutes, after cleaning, it is dried in an oven at 80°C and stored properly. Using electron beam evaporation technology, using calcium silicate as the evaporation target material, the polyether ether ketone material is subjected to electron beam evaporation. The specific process parameters are shown in Table 3, and the obtained sample number is EBE-8min;

[0049] Table 3 E-beam evaporation parameters:

[0050] Electron beam excitation voltage (kV)

8.5

electron beam current

1.6A

Evaporation time(min)

8

Background vacuum (Pa)

5×10 -3

[0051] ;

[0052] The silicon content on the surface of the modified polyetheretherketone material was 7.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com