A kind of cross-linked polyethylene and its production process

A cross-linked polyethylene and production process technology, applied in the field of polymer compound production, can solve problems such as difficult control of conditions, influence on product performance, complicated operation, etc., and achieve stable product performance, simple structure of production equipment, and excellent properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

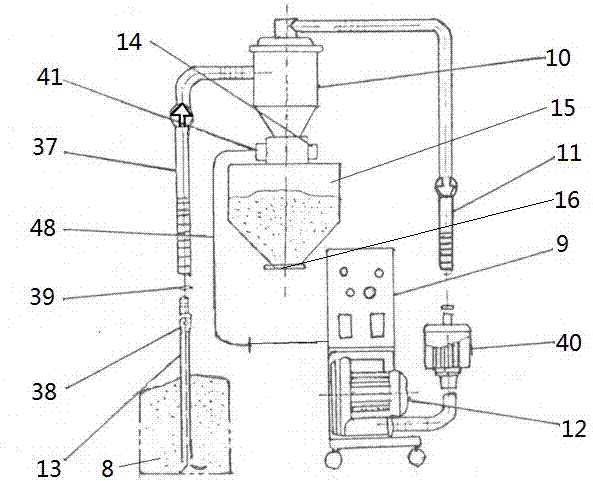

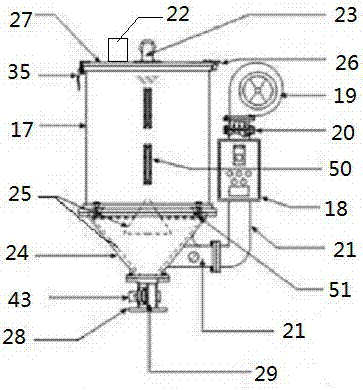

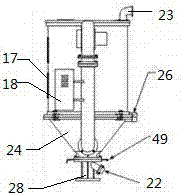

[0027] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0028] A cross-linked polyethylene, comprising linear low density polyethylene, low density polyethylene, catalyst, antioxidant, silane crosslinking agent, initiator and lubricant, the catalyst is dibutyltin laurate compound, silane crosslinking The agent is vinyltrimethoxysilane, and the initiator is dicumyl peroxide, wherein the proportions by weight of each component are as follows:

[0029] 20-80 parts of linear low-density polyethylene, 20-80 parts of low-density polyethylene, 1-3 parts of dibutyltin laurate compound, 1-2 parts of antioxidant, 0.5-2 parts of vinyltrimethoxysilane, Dicumyl oxide 0.01-0.04 parts, lubricant 1-4 parts.

[0030] The production process of above-mentioned cross-linked polyethylene, comprises the steps:

[0031] 1) Preparation of catalyst masterbatch: The catalyst masterbatch includes low density polyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com