Butadiene-acrylonitrile rubber material for automobile engine shock absorption and preparation method thereof

An automobile engine and nitrile rubber technology, applied in the field of rubber materials, can solve the problems of poor high temperature aging resistance and ozone resistance of natural rubber, hidden dangers of automobile safety, failure to work normally, etc., and achieves increased flexibility, reduced resilience, Component simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

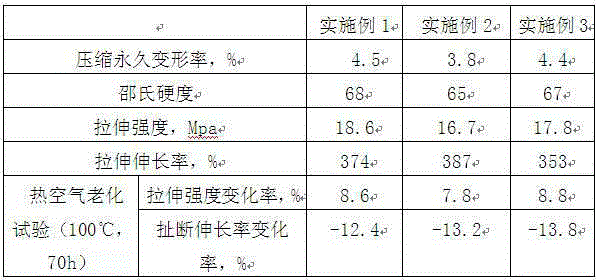

Examples

Embodiment 1

[0016] A nitrile rubber material for automobile engine shock absorption, which is prepared from the following raw materials in parts by weight (kg): nitrile rubber 70, natural rubber 30, acrylic rubber 14, capric triglyceride 5, terephthalic acid Diethyl ester 6, distearoyl isopropoxy aluminate 5, triallyl isocyanurate 7, methyl ethoxy silicone oil 6, carbon fiber 10, acrylic pulp 15, diamond powder 6, Nano Zinc Oxide 4, Dibutyltin Dilaurate 6, Benzoylacetone 4, Sulfur 2, 1,4-Cyclohexanedimethanol 1, Tetrahydrofuryl Methyl Oleate 3, Antimony Tin Oxide 8, Potassium Titanate Whiskers 6 16. Sepiolite wool.

[0017] A preparation method of acrylonitrile-butadiene rubber material for automobile engine shock absorption, comprising the following steps:

[0018] (1) Put nitrile rubber and natural rubber into the internal mixer for 2-3 minutes to make the temperature reach 90-100°C, then continue to add acrylate rubber, capric triglyceride, diethyl terephthalate, diethyl terephthalate...

Embodiment 2

[0023] A nitrile rubber material for automobile engine shock absorption, which is prepared from the following raw materials in parts by weight (kg): nitrile rubber 80, natural rubber 35, acrylate rubber 16, capric triglyceride 6, terephthalic acid Diethyl Ester 7, Distearoyl Isopropoxy Aluminate 5.5, Triallyl Isocyanurate 8, Methyl Ethoxy Silicone Oil 7.5, Carbon Fiber 12, Acrylic Pulp 17.5, Diamond Powder 7, Nano Zinc Oxide 5, Dibutyltin Dilaurate 7, Benzoylacetone 4.5, Sulfur 2.5, 1,4-Cyclohexanedimethanol 1.5, Tetrahydrofuryl Methyl Oleate 4, Antimony Tin Oxide 9, Potassium Titanate Whiskers 7.5 17. Sepiolite wool.

[0024] The preparation method is the same as in Example 1.

Embodiment 3

[0026] A nitrile rubber material for automobile engine shock absorption, which is prepared from the following raw materials in parts by weight (kg): nitrile rubber 90, natural rubber 40, acrylate rubber 18, capric triglyceride 7, terephthalic acid Diethyl ester 8, distearyloxy isopropoxy aluminate 6, triallyl isocyanurate 9, methyl ethoxy silicone oil 9, carbon fiber 14, acrylic pulp 20, diamond powder 8, Nano Zinc Oxide 6, Dibutyltin Dilaurate 8, Benzoylacetone 5, Sulfur 3, 1,4-Cyclohexanedimethanol 2, Tetrahydrofuryl Methyl Oleate 5, Antimony Tin Oxide 10, Potassium Titanate Whiskers 9 18. Sepiolite wool.

[0027] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com