Catalyst for methacrylic acid production, method for producing same, and method for producing methacrylic acid

A technology of methacrylic acid and manufacturing methods, applied in the direction of catalyst activation/preparation, organic chemical methods, chemical instruments and methods, etc., can solve the problems of insufficient and uneconomical catalyst reaction results, and achieve high selectivity and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

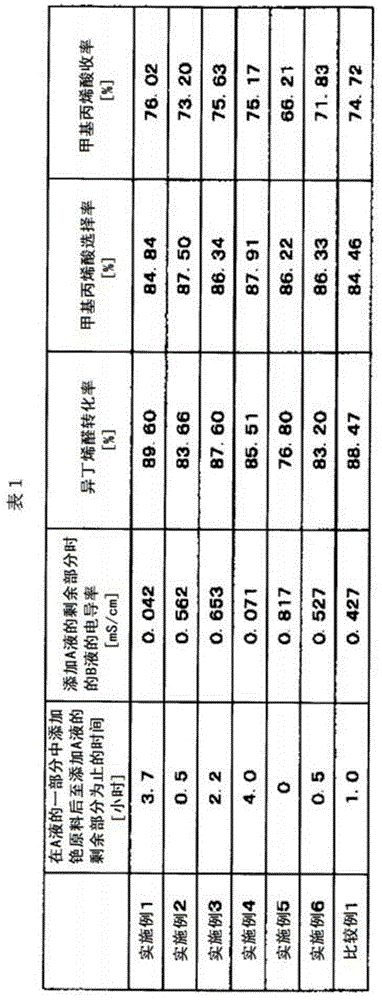

Embodiment 1

[0075] 1) Preparation of catalyst

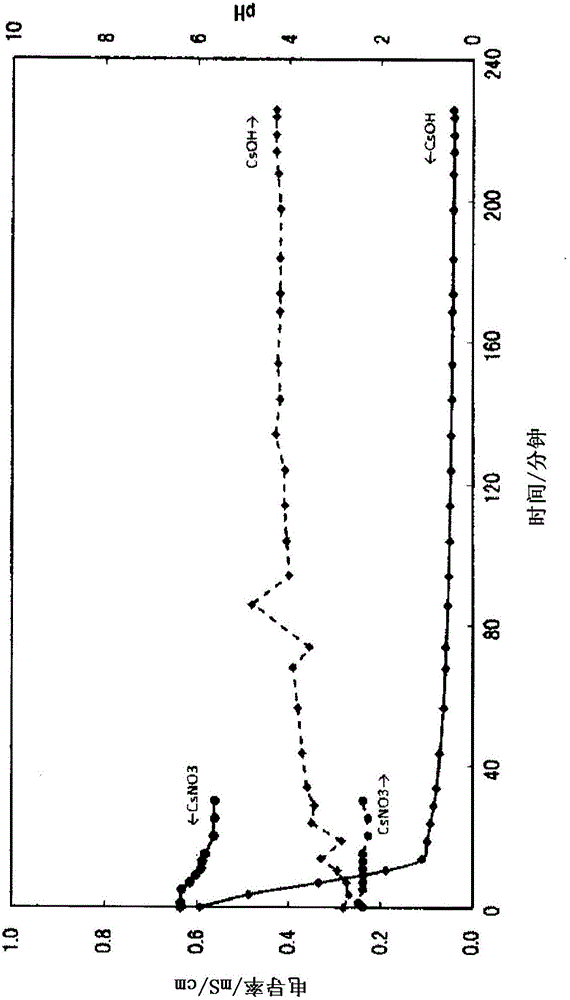

[0076] 800 g of molybdenum trioxide, 30.33 g of vanadium pentoxide, and 76.87 g of 85% by mass orthophosphoric acid were added to 5680 ml of pure water, and heated and stirred at 92° C. for 3 hours to obtain a reddish-brown transparent solution (liquid A). The average particle size of the molybdenum trioxide used at this time was 1.5 μm. Next, this solution was cooled to 0-20 degreeC, and 944.31g was taken into another container. Then, 661.32 g of a 9.1% by mass cesium hydroxide aqueous solution was slowly added to the solution taken into the other container while stirring, and aged at 15 to 20° C. until the electrical conductivity reached neutralization to obtain a yellow slurry (B liquid ). The electrical conductivity was measured using a conductivity meter (CM-60G) manufactured by DKK Toa Corporation. In addition, the electrical conductivity and the pH value (Y axis) of the mixed solution obtained by adding the cesium hydroxide aqueous...

Embodiment 2

[0082] Except changing 661.32 g of the 9.1 mass % cesium hydroxide aqueous solution in Example 1 to 417.07 g of 9.1 mass % cesium nitrate aqueous solution, the coated catalyst was prepared by the same method as in Example 1, and the methacrolein catalyst was supplied. oxidation reaction. In addition, the electrical conductivity and the pH value (Y axis) of the mixed solution obtained by adding the cesium nitrate aqueous solution to the A liquid and the time (X axis) changes are shown in figure 1 .

Embodiment 3

[0084] In Example 1, except that 15.51 g of a 30% by mass aqueous hydrogen peroxide solution was added before the addition of the cesium hydroxide aqueous solution, a coated catalyst was prepared in the same manner as in Example 1, and used for the catalyst oxidation reaction of methacrolein.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com