Preparing method for corrosion-resistant gas diffusion layer of fuel cell

A gas diffusion layer and fuel cell technology, applied in fuel cells, solid electrolyte fuel cells, electrical components, etc., to overcome agglomeration, improve corrosion resistance and stability, and improve dispersion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

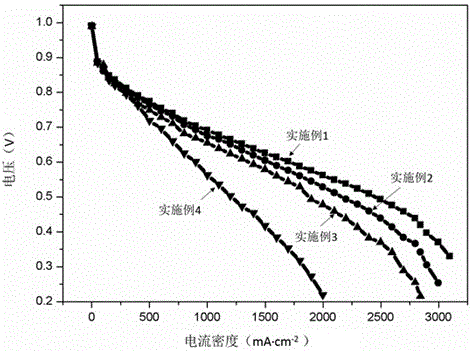

Embodiment 1

[0029] Dissolve polyvinylpyrrolidone (PVP) in deionized water, and the mass ratio of PVP to deionized water is 1:1999 (that is, the mass percentage of PVP in the solution is 0.5‰); measure 15 ml of the solution, and add two Tin oxide (SnO 2 ) nanopowder and indium oxide (In 2 o 3 ) A total of 75 mg of nano powder (ie SnO 2 and In 2 o 3 The mass percentage of nano powders in the total solution is 0.5%), fully mechanically stirred for 0.5 hours, and then ultrasonically dispersed for 30 minutes to form a uniform suspension; then add polytetrafluoroethylene (PTFE) with a mass fraction of 10% to it A total of 30 mg of emulsion (i.e. the mass of PTFE as SnO 2 and In 2 o 3 4% of the total mass of the nanometer powder), stirred slowly for 10 minutes to form a microporous layer slurry; prepare a carbon fiber paper with a porosity of 30% and a thickness of 190 microns as the support layer, and use the prepared microporous layer slurry The glass rod is rolled onto one side of the...

Embodiment 2

[0032] Dissolve alkylphenol polyoxyethylene ether (APEO) in deionized water, and the mass ratio of APEO to deionized water is 1:666 (that is, the mass percentage of APEO in the solution is 1.5‰); measure 15 ml of the solution, Add a total of 464 mg of fluorine-doped tin dioxide (FTO) nanopowder to it (that is, the mass percentage of FTO nanopowder in the total solution is 3%), fully mechanically stir for 1 hour, and then ultrasonically disperse for 40 minutes to form a uniform suspension liquid; adding thereto a total of 462 mg of tetrafluoroethylene and hexafluoropropylene copolymer (FEP) emulsion with a mass fraction of 10% (that is, the quality of FEP is 10% of the FTO nano-powder quality), and stirred slowly for 15 minutes, Form the microporous layer slurry; prepare a carbon fiber paper with a porosity of 45% and a thickness of 200 microns as a support layer, and roll the prepared microporous layer slurry onto one side of the carbon fiber paper support layer with a glass ro...

Embodiment 3

[0035]Dissolve polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer (PEO-PPO-PEO) in deionized water, and the mass ratio of PEO-PPO-PEO to deionized water is 1:332 (that is, PEO-PPO -PEO accounted for the mass percent of the solution is 3 ‰); measure 15 milliliters of the solution, to which 789 mg of aluminum-doped zinc dioxide (AZO) nanopowder was added (that is, the mass percent of AZO nanopowder accounted for the total solution was 5 %), fully mechanically stirred for 1 hour, and then ultrasonically dispersed for 50 minutes to form a uniform suspension; then add 1.58 grams of polyvinylidene fluoride (PVDF) emulsion with a mass fraction of 10% (that is, the mass of PVDF is AZO nano 20% of the mass of the powder), stirred slowly for 20 minutes until uniform to form a microporous layer slurry; prepare a carbon fiber paper with a porosity of 60% and a thickness of 150 microns as the support layer, and use the prepared microporous layer slurry The glass rod is rolled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com