Lithium ion battery composite pole piece, preparation method thereof and lithium ion battery

A lithium-ion battery and battery pole piece technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte battery electrodes, etc., can solve problems such as battery temperature rise, inability to efficiently ensure battery safety, etc., and achieve low hardness and reduced Process loss, the effect of suppressing further increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

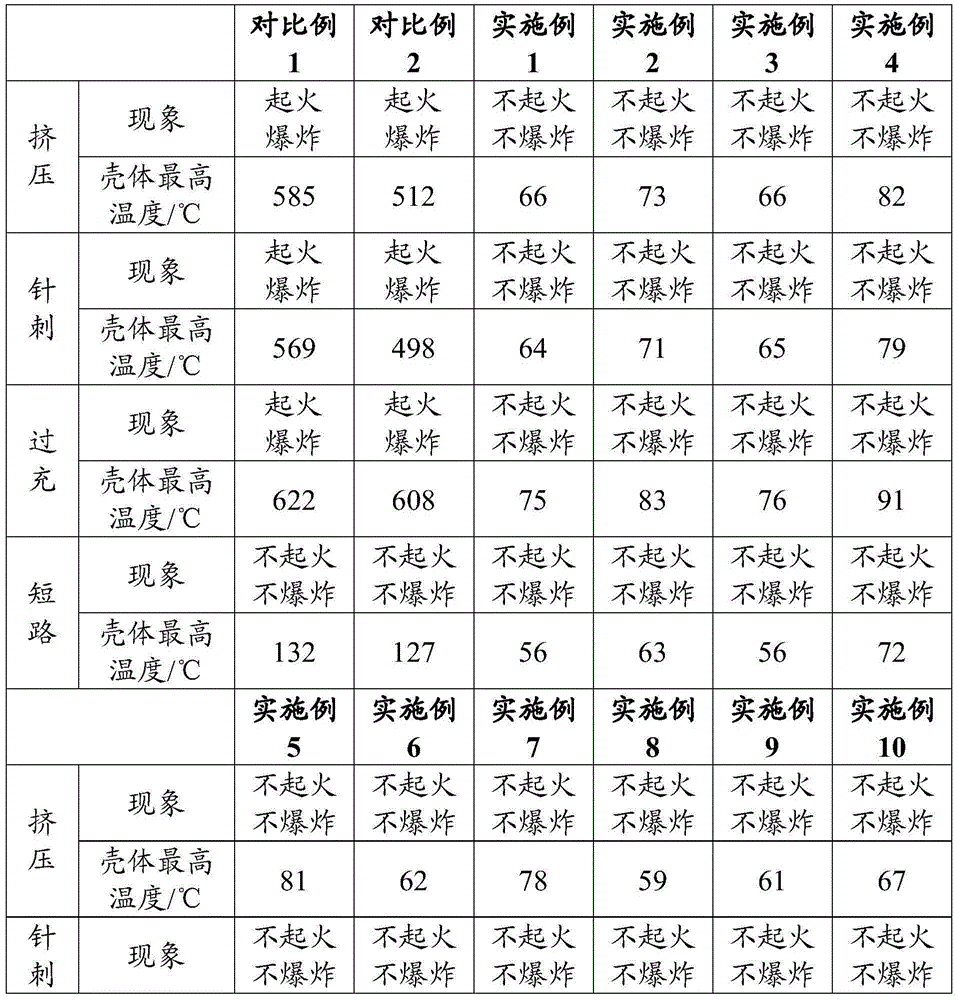

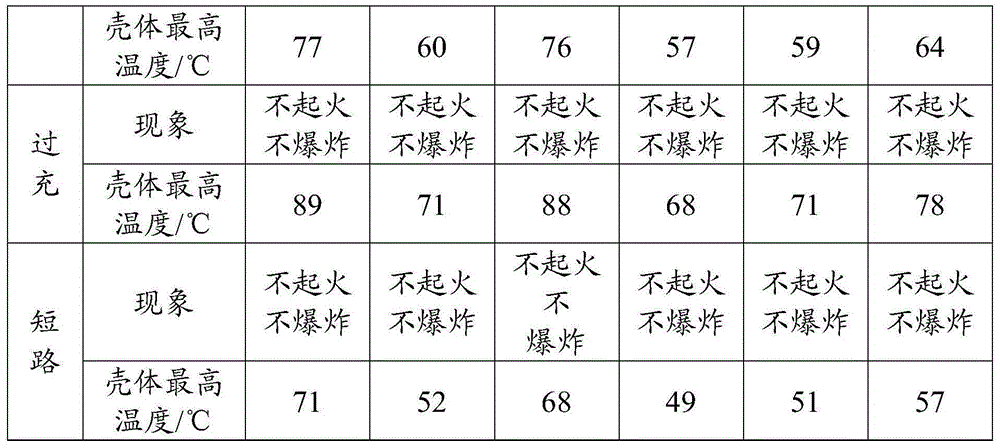

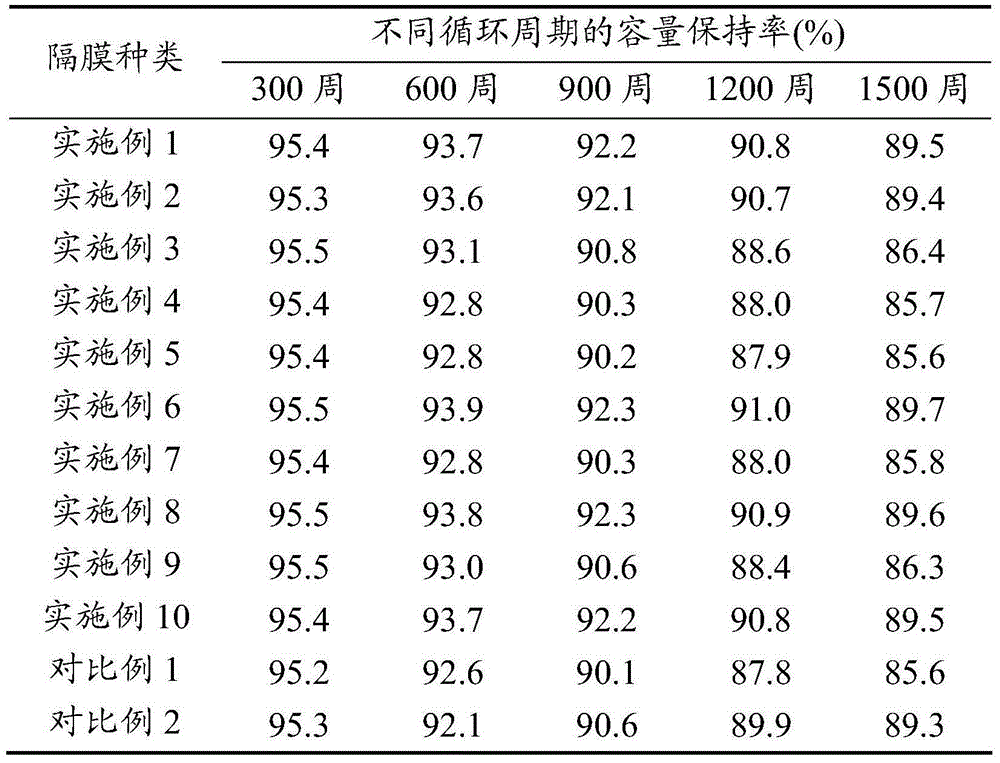

Examples

preparation example Construction

[0025] The present invention has no special limitation on the preparation method of the positive electrode of the battery, and the preparation method of the positive electrode of the battery known to those skilled in the art will suffice. In the present invention, it is preferably prepared according to the following method:

[0026] a1) dispersing the active material, conductive agent and binder of the positive electrode of the battery in a solvent to obtain a positive electrode slurry;

[0027] b1) coating the positive electrode slurry on the positive electrode current collector, and rolling after drying to obtain the positive electrode of the battery.

[0028] In the present invention, firstly, the active material, conductive agent and binder of the positive electrode of the battery are dispersed in a solvent to obtain positive electrode slurry. Wherein, the present invention has no special limitation on the types of the conductive agent and the binder, and the conductive a...

Embodiment 1

[0087] a Preparation of positive electrode sheet

[0088] The active material LiFePO was added to the solvent deionized water with a mass fraction of 93 wt%. 4 , 3.5wt% conductive agent carbon black and 3.5wt% binder LA132, mixed uniformly to obtain a ternary positive electrode slurry, and the positive electrode slurry was uniformly coated on a positive electrode current collector Al foil with a thickness of 20 μm, and dried to obtain Positive electrode, rolled for standby.

[0089] b preparation of mixed slurry;

[0090] Accurately weigh melamine cyanurate (MCA) and polyvinylidene fluoride film (PVDF) according to the mass ratio of 97:3. On a high-speed disperser, MCA and PVDF were uniformly dispersed in the solvent N-methylpyrrolidone (NMP) to obtain MCA slurry and PVDF slurry, and then the two slurries were stirred evenly, and the solvent NMP was used to control the concentration in the slurry. The solid content was 50 wt%, and a mixed slurry was obtained.

[0091] Prep...

Embodiment 2

[0099] a Preparation of positive electrode sheet

[0100] The active material LiFePO was added to the solvent deionized water with a mass fraction of 93 wt%. 4 , 3.5wt% conductive agent carbon black and 3.5wt% binder LA132, mixed uniformly to obtain a ternary positive electrode slurry, and the positive electrode slurry was uniformly coated on a positive electrode current collector Al foil with a thickness of 20 μm, and dried to obtain Positive electrode, rolled for standby.

[0101] b Preparation of negative electrode sheet

[0102] Add mass fraction to solvent deionized water and be respectively 95wt% negative active material graphite powder, 2wt% conductive agent KS-6, 1wt% thickener CMC (sodium carboxymethyl cellulose) and 2wt% binding agent SBR (styrene-butadiene rubber) was mixed evenly to obtain negative electrode slurry, and the negative electrode slurry was uniformly coated on a negative electrode current collector Cu foil with a thickness of 10 μm, dried to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com