Crystalline silicon solar cell front electrode silver paste

A solar cell, front electrode technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor wettability, difficult to achieve the performance of lead-containing glass powder, high glass transition temperature, and achieve good wettability, good contact, The effect of low glass viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0027] Embodiments 1 to 5: a silver paste for the front electrode of a crystalline silicon solar cell, the front silver conductive paste is composed of the following components by weight, as shown in Table 1:

[0028] Table 1

[0029]

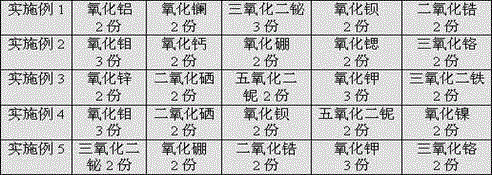

[0030] The oxide additive is composed of the following components by weight, as shown in Table 2:

[0031] Table 2

[0032]

[0033] The above-mentioned organic solvent is at least one of terpineol, butyl carbitol, butyl carbitol acetate and propylene glycol methyl ether acetate.

[0034] Embodiment 1 silver conductive phase is made up of flake silver powder 9%, spherical silver powder 85% and nano silver powder 6%, and embodiment 2 silver conductive phase is made up of flake silver powder 7%, spherical silver powder 88% and nano silver powder 5%, embodiment 3 The silver conductive phase is composed of 12% flake silver powder, 82% spherical silver powder and 6% nano silver powder; embodiment 4 The silver conductive phase is composed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com