Front electrode silver paste of lead-free solar cell

A technology of solar cells and front electrodes, which is applied to conductive materials, circuits, and electrical components dispersed in non-conductive inorganic materials, can solve the problems of poor wettability, difficult to achieve the performance of lead-containing glass powder, and high glass transition temperature. Achieve the effects of good wettability, good electrical conductivity and low glass viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

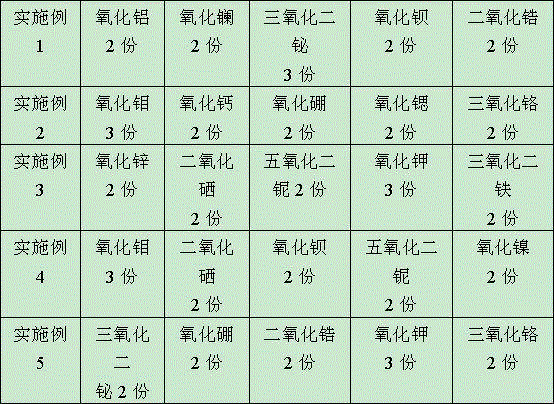

[0028] Embodiments 1 to 5: a silver paste for the front electrode of a lead-free solar cell, the front silver conductive paste is composed of the following components by weight, as shown in Table 1:

[0029] Table 1

[0030]

Example 1 Example 2 Example 3 Example 4 Example 5 silver conductive phase 80 copies 85 copies 76 copies 88 copies 90 copies Organic solvents 9 servings 10.2 copies 12 copies 11 copies 5.95 servings Ethyl cellulose 0.8 parts 0.6 parts 1 copy 0.9 parts 0.6 parts Butyl cellulose 0.7 parts 0.6 parts 0.5 parts 0.8 parts 0.7 parts Hydroxycellulose 0.5 parts 0.6 parts 0.7 parts 0.65 servings 0.75 parts sodium oxide 0.6 parts 0.48 parts 0.5 parts 0.5 parts 0.3 parts tellurium dioxide 1.15 servings 1.21 copies 1.3 parts 1.25 servings 0.78 parts Tungsten trioxide 0.7 parts 0.83 parts 0.9 parts 1 copy 0.55 parts oxide additiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com