Asphalt separant and preparation method thereof

A technology of isolation agent and asphalt, applied in the direction of coating, etc., can solve the problems of large influence of asphalt mixture performance, poor isolation effect of asphalt isolation agent, little influence of asphalt mixture performance, etc., so as to improve the sticking phenomenon and improve the construction environment. , Improve the effect of road compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

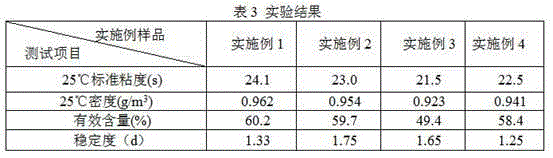

Examples

Embodiment 1

[0026] A kind of asphalt release agent, used for anti-sticking in asphalt mixture transportation and construction, comprises the following components in parts by weight: 6 parts of simethicone, 1.5 parts of fatty alcohol polyoxyethylene ether (AEO), 0.5 part Alkylphenol polyoxyethylene ether OP-10, 4 parts of glycerin, 80 parts of soybean oil, 40 parts of water, 0.6 parts of sodium benzoate, 0.3 parts of fragrance.

[0027] The preparation method is as follows: first heat each component to 60°C in advance, add simethicone, glycerol, and soybean oil into a reaction kettle at a constant temperature of 80°C in sequence, stir for 10 minutes, and then add fatty alcohol polyoxyethylene ether ( AEO), alkylphenol polyoxyethylene ether OP-10 and water, stirred for 20 minutes, then emulsified 3 times through a colloid mill at a speed of 6000r / min, and added preservatives and fragrances during the emulsification process. The asphalt release agent.

Embodiment 2

[0029] A kind of asphalt release agent, comprises following components by weight parts: 5 parts of simethicone oils, 1.5 parts of fatty alcohol polyoxyethylene ethers (AEO), 5 parts of glycerol, 70 parts of rapeseed oils, 35 parts of water , 0.6 parts of potassium sorbate, 0.2 parts of fragrance.

[0030] The preparation method is as follows: first heat each component to 70°C in advance, add simethicone oil, glycerol, and rapeseed oil into a constant temperature reaction kettle at 70°C in sequence, stir for 20 minutes, and then add fatty alcohol polyoxyethylene ether (AEO) and water, stirred for 15 minutes, and then passed through a colloid mill at a speed of 5000r / min for 3 times of high-speed shear emulsification to obtain the product, and the asphalt release agent was obtained by adding preservatives and fragrances during the emulsification process.

Embodiment 3

[0032] A kind of bitumen release agent, by weight, comprises the following components: 9 parts of simethicone, 1.8 parts of fatty acid methyl ester sulfonate (MES), 10 parts of glycerol, 80 parts of cottonseed oil, 60 parts of water, 0.8 parts sodium benzoate, 0.25 parts fragrance.

[0033] The preparation method is as follows: first preheat each component to 80°C, add dimethyl silicone oil, glycerol, and cottonseed oil in the order of 80°C constant temperature reaction kettle, stir for 15 minutes, and then add fatty acid methyl ester sulfonic acid Stir salt (MES) and water for 10 minutes, and then pass through a colloid mill for high-speed shear emulsification 3 times at a speed of 4000r / min. Add preservatives and fragrances during the emulsification process to obtain the asphalt release agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com