Preparation method of oil-resistant isoprene functional rubber and product thereof

A technology of isoprene and rubber, which is applied in the field of isoprene ternary rubber preparation method and its products, can solve the problems of lack of heat resistance and weather resistance, single isoprene rubber performance, poor wear resistance, etc., and achieve improvement Oil resistance, improved abrasion resistance and tensile properties, and the effect of achieving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Deionized water, emulsifier sodium dodecylbenzenesulfonate (SDBS), electrolytes KCl and K 3 PO 4 1. The monomers are isoprene (IP), limonene (LIM) and butyl acrylate (BA), and the above substances are sequentially added into a pressure reactor to obtain a polymerization system.

[0037] Wherein, 250 g of deionized water was added, the total mass of monomers was 100 g, and the mass ratio of isoprene (IP), limonene (LIM), and butyl acrylate (BA) was 6:3:1. The added amount of SDBS accounts for 2% of the total mass of the monomer, the mass of potassium chloride accounts for 0.5% of the total mass of the monomer, and the mass of potassium phosphate accounts for 0.2% of the total mass of the monomer. The addition amount of initiator potassium persulfate is 0.2% of the total mass of monomers.

[0038] 2) Treat the reactor containing the polymerization system with N 2 Evacuate 5 times to get rid of the air in the reactor. Then the reactor is heated to 30°C, the pressure...

Embodiment 2

[0046] 1) Deionized water, emulsifier sodium dodecylbenzenesulfonate (SDBS), electrolytes KCl and K 3 PO 4 , monomer isoprene (IP), limonene (LIM) and dibutyl itaconate (DBI) were sequentially added into the pressure reactor to obtain a polymerization system.

[0047] Wherein, 250 g of deionized water was added, the total mass of the monomer was 100 g, and the mass ratio of isoprene (IP), limonene (LIM), and dibutyl itaconate (DBI) was 6:3:1. The added amount of SDBS accounts for 2% of the total mass of the monomer, the mass of potassium chloride accounts for 0.5% of the total mass of the monomer, and the mass of potassium phosphate accounts for 0.2% of the total mass of the monomer. The addition amount of initiator potassium persulfate is 0.2% of the total mass of monomers.

[0048] 2) Treat the reactor containing the polymerization system with N 2 Evacuate 5 times to get rid of the air in the reactor. Then the reactor was heated to 30°C, the pressure inside it was adjust...

Embodiment 3-6

[0051] In order to study the influence of different feed ratios on the copolymerization product PLIB, the total number of monomers was selected as 100 parts, the mass fraction of fixed limonene was 30 parts, and the feeding rate of butyl acrylate was 10 parts, 20 parts, 30 parts, 40 parts, and other The reaction conditions are: the total mass of the monomer is 100g, deionized water 200g, SDBS2g, KCl0.5g, K 3 PO 4 0.2g, K 2 S 2 o 8 0.25g.

[0052] Put the above polymerization system at 30℃ and 1MPa N 2 Pre-emulsify under atmosphere for 1 hour, then raise the temperature to 70° C., and react for 8 hours. After the reaction, the rubber was demulsified and coagulated with a calcium chloride solution with a concentration of 2 wt %, washed repeatedly with deionized water, and dried to obtain a copolymerized product.

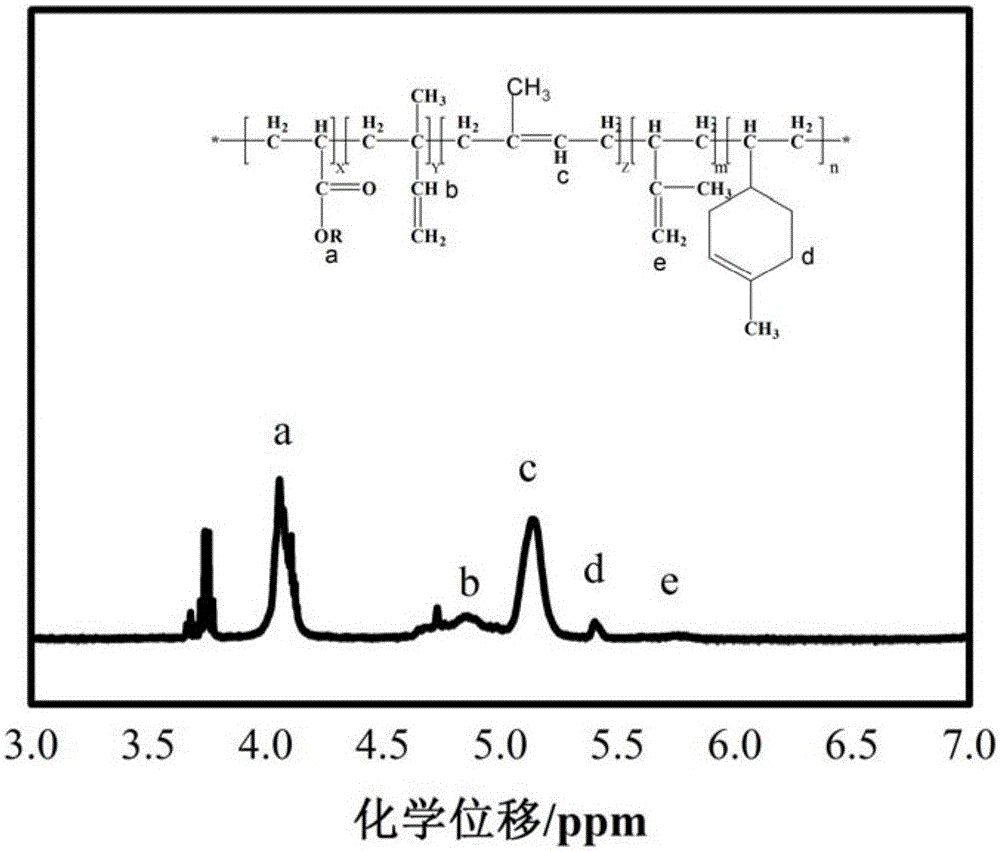

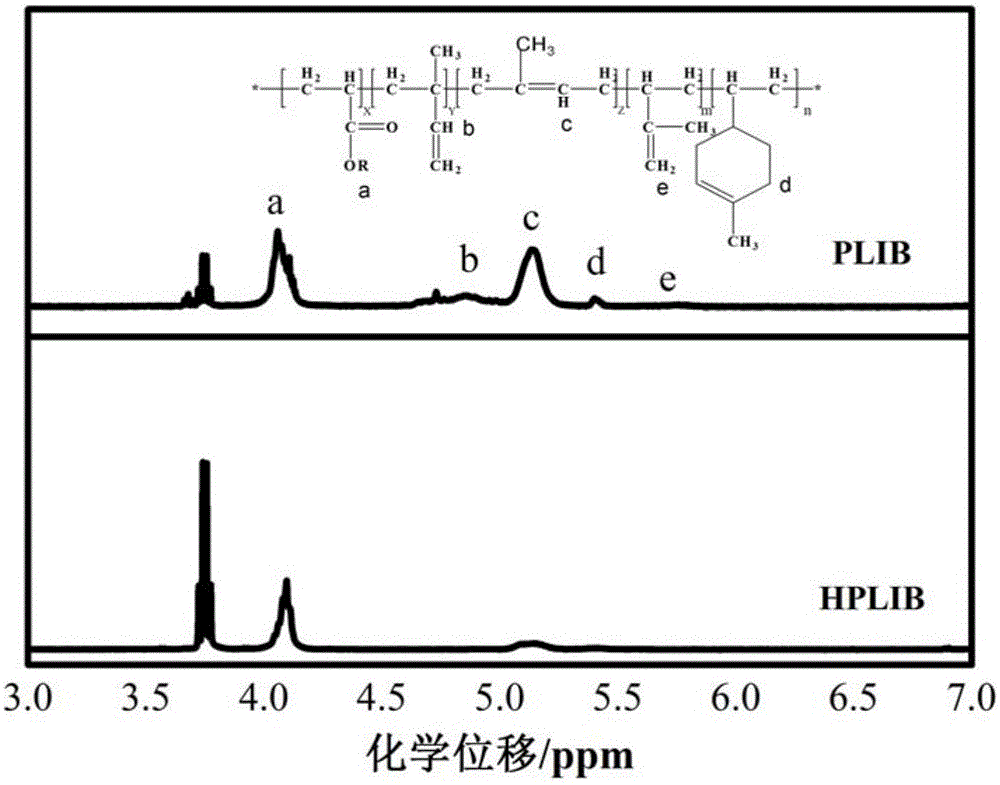

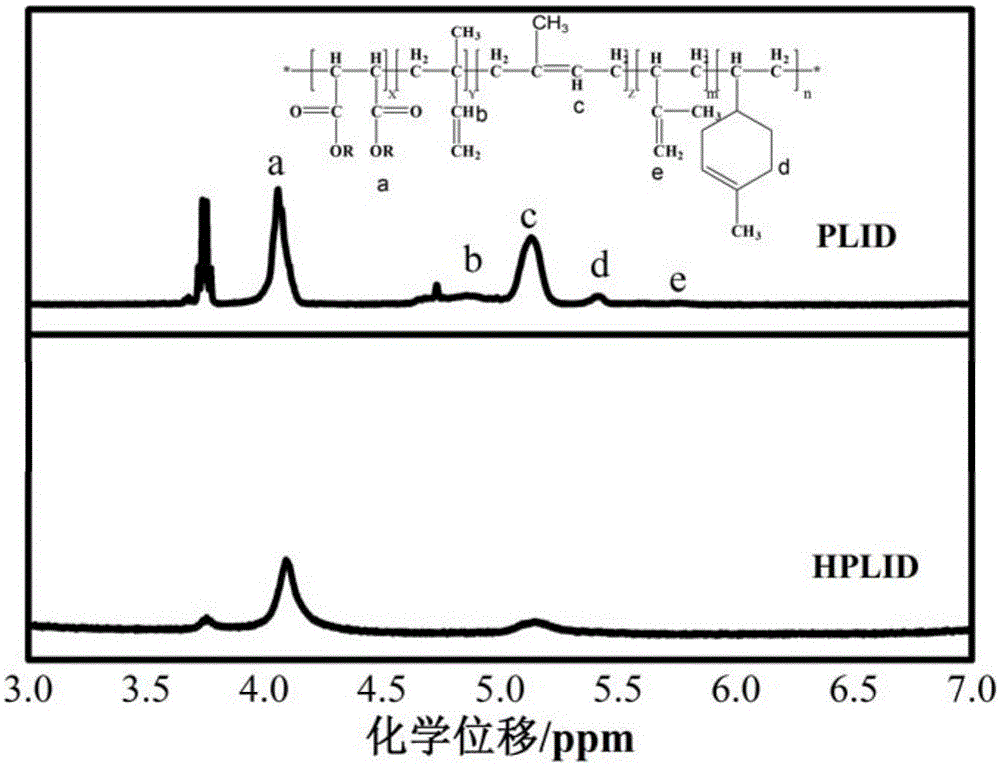

[0053] The change of the copolymerization composition of PLIB with the feed ratio and the determination of its molecular weight are shown in Table 1 using nuclea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com