Terpolymer emulsion containing non-ionic emulsifier and preparation method therefor

A technology of non-ionic emulsifier and terpolymer, which is applied in the field of anticorrosion of metal materials and coatings. It can solve the problems of affecting the anticorrosion performance of coatings, poor coating film compactness, and decreased coating film adhesion. It can achieve easy control of reaction speed and durability Good acid-base properties and high film density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

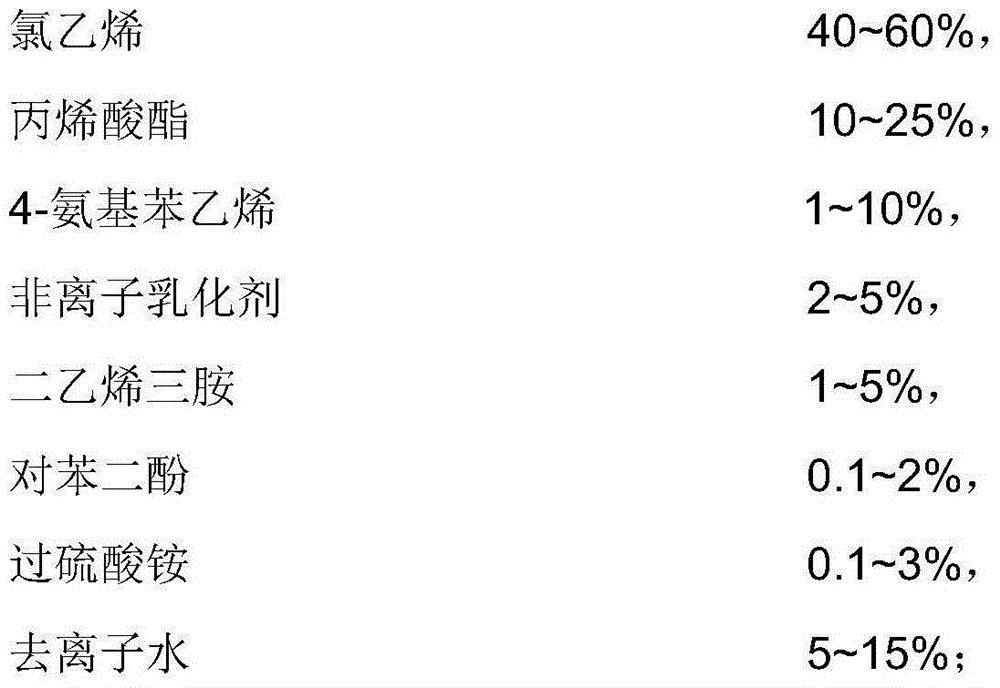

[0034] 1. The components are proportioned according to mass percentage:

[0035]

[0036] 2. Preparation method:

[0037] (1) Add deionized water, acrylate, diethylenetriamine, 50% nonionic emulsifier, 50% ammonium persulfate and 50% vinyl chloride to the reactor, and rapidly heat up to 65°C-100°C, At the same time, continuously stir at a stirring speed of 1000-1500r / min, keep warm for 4-15 hours, and obtain a vinyl chloride-acrylate emulsion;

[0038] (2) Control the temperature of the reactor at 65°C to 100°C, and add the remaining 50% of vinyl chloride, 50% of ammonium persulfate and 50% of Nonionic emulsifier, and slowly add 4-aminostyrene dropwise, keep warm for 4-15 hours after the dropwise addition, and add hydroquinone;

[0039] (3) The resulting product is filtered through an 800-mesh filter to obtain a terpolymer emulsion containing a nonionic emulsifier.

[0040] Three, the beneficial effect of this embodiment:

[0041] The average particle diameter of the em...

Embodiment 2

[0043] 1. Components are proportioned according to mass percentage

[0044]

[0045]

[0046] Two, preparation method is identical with embodiment 1.

[0047] Three, the beneficial effect of this embodiment:

[0048] The average particle diameter of the emulsion particle concentration of the polymer emulsion measured by a nanoparticle size analyzer is about 6.7nm

[0049] Right; the measured solid content is 28.4%; the water resistance is 72 hours without whitening or blistering.

Embodiment 3

[0051] 1. The components are proportioned according to mass percentage:

[0052]

[0053] Two, preparation method is identical with embodiment 1.

[0054] Three, the beneficial effect of this embodiment:

[0055] The average particle diameter of the emulsion particle concentration of the polymer emulsion measured by a nanometer particle size analyzer is about 3.5nm; the measured solid content is 21.4%; the water resistance is 70h without whitening or foaming.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com