Automatic production device for environment-protective ecological wood board and method thereof

An automatic production method and automatic production technology, which is applied in the direction of wood processing equipment, wooden veneer joints, manufacturing tools, etc., can solve the problem that the quality of the panel is difficult to meet the requirements of the gluing process, and at the same time, the extrusion pressure is limited, which affects the bonding strength. and other issues to achieve the effect of promoting product balance, reducing waste, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

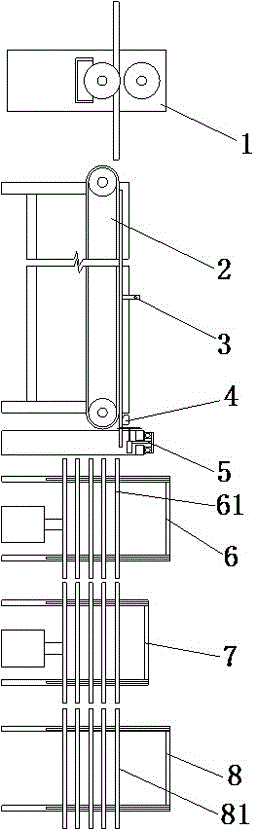

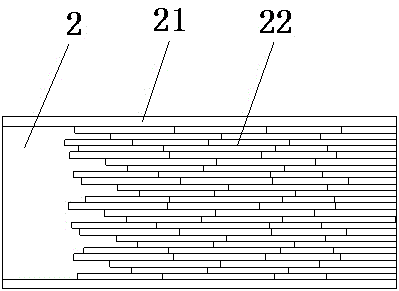

[0030] Embodiment one: if Figure 1~2 As shown, an automatic production device for environmentally friendly ecological woodworking boards, including a glue applicator 1, a jigsaw machine, a sawing machine 5, a conversion machine 6, a heat press machine 7, a radiator 8 and a control panel arranged in sequence along the direction of material travel The control system for the operation of the device, the jigsaw machine includes a conveyor belt 2, the two sides of the conveyor belt 2 are provided with baffles 21, the sawing machine 5 includes a bracket that is set at the exit of the conveyor belt and spans the conveyor belt, on the bracket It is provided with a saw blade machine that moves left and right along the bracket, and also includes a distance measuring sensor 3 arranged on the conveyor belt. The distance measurement sensor 3 detects the length of the wood board and controls the operation of the saw blade machine. Lifting receiving boards 61, these receiving boards 61 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com