Dendrobium cultivation matrix and preparation method thereof

A cultivation substrate and technology of dendrobium, which is applied in the field of cultivation substrate and preparation of plants to achieve the effect of being less moldy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

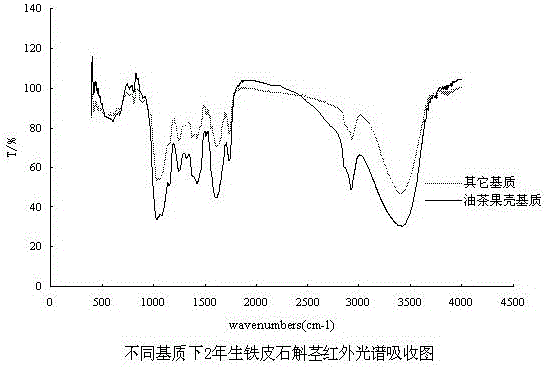

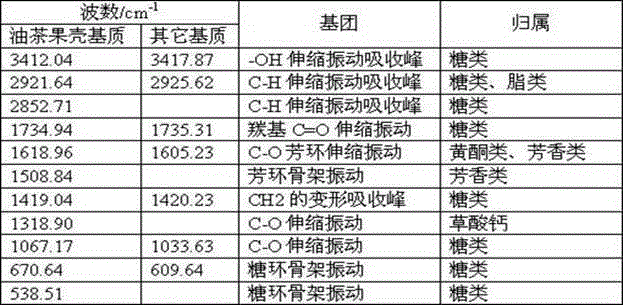

Image

Examples

Embodiment 1

[0022] In terms of weight percentage, mix 70% camellia oleifera husk, 10% camellia oleifera meal, 5% chestnut shell, 5% walnut shell, and 10% polyurethane slow-release fertilizer, spread it on bluestone or bricks or install After potting, water it to make its humidity about 60%. After planting tissue cultured Dendrobium seedlings or transplanting Dendrobium seedlings, the survival rate is 99%. The average plant height, stem diameter, leaf length, leaf width, etc. are significantly better than other substrates. After one and a half years of growth in substrate cultured dendrobium, the chemical composition was detected, and the polysaccharide content of dendrobium was 49%.

Embodiment 2

[0024] In terms of weight percentage, mix 60% camellia husk, 20% camellia oleifera meal, 5% moss, 5% pine bark, and 10% polyurethane slow-release fertilizer, spread it on bluestone or bricks or put it in a pot After that, water it to make its humidity about 60%. After planting tissue cultured Dendrobium seedlings or transplanting Dendrobium seedlings, the survival rate is 99%. The average plant height, stem diameter, leaf length, leaf width, etc. are significantly better than other substrates. The chemical composition of the cultivated Dendrobium was detected after one year of growth, and the polysaccharide content of Dendrobium was 47.9%.

Embodiment 3

[0026] In terms of weight percentage, mix 50% camellia husk, 25% camellia oleifera meal, 5% moss, 5% chestnut shell, and 15% polyurethane slow-release fertilizer, spread it on bluestone or bricks or put it in a pot After that, water it to make its humidity about 60%. After planting tissue cultured Dendrobium seedlings or transplanting Dendrobium seedlings, the survival rate is 99%. The average plant height, stem diameter, leaf length, leaf width, etc. are significantly better than other substrates. The chemical composition of the cultivated Dendrobium was tested after one and a half years of growth, and the polysaccharide content of Dendrobium was 49.98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com