Horizontal condensing coal heating furnace

A technology of condensing and heating furnaces, which is applied in the direction of fluid heaters, air heaters, lighting and heating equipment, etc. It can solve the problems of large smoke and dust emissions and low thermal efficiency, reduce floor space, improve thermal efficiency, and solve fog The effect of haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

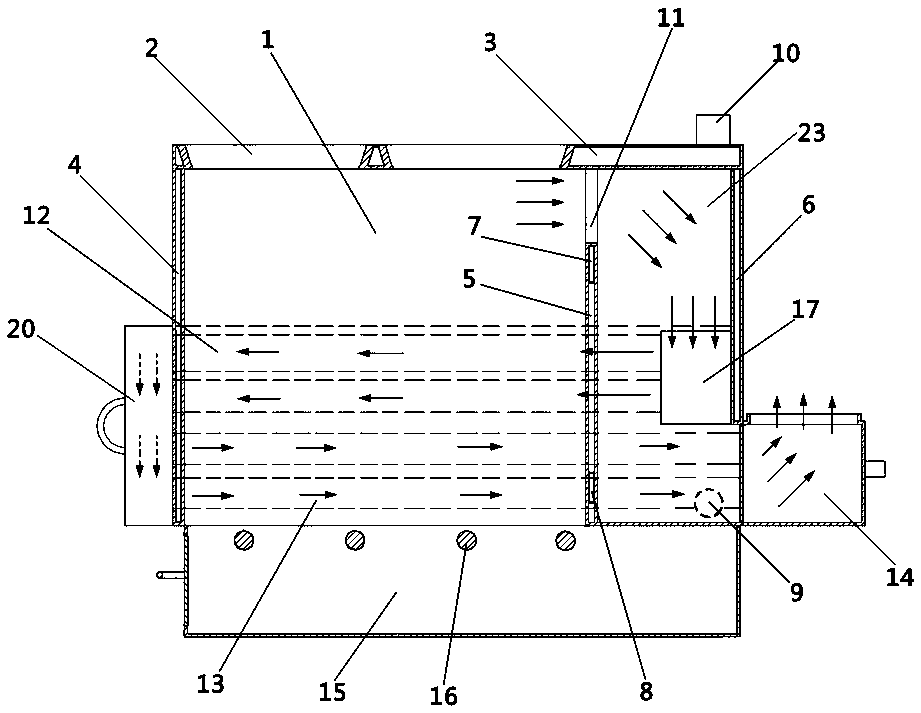

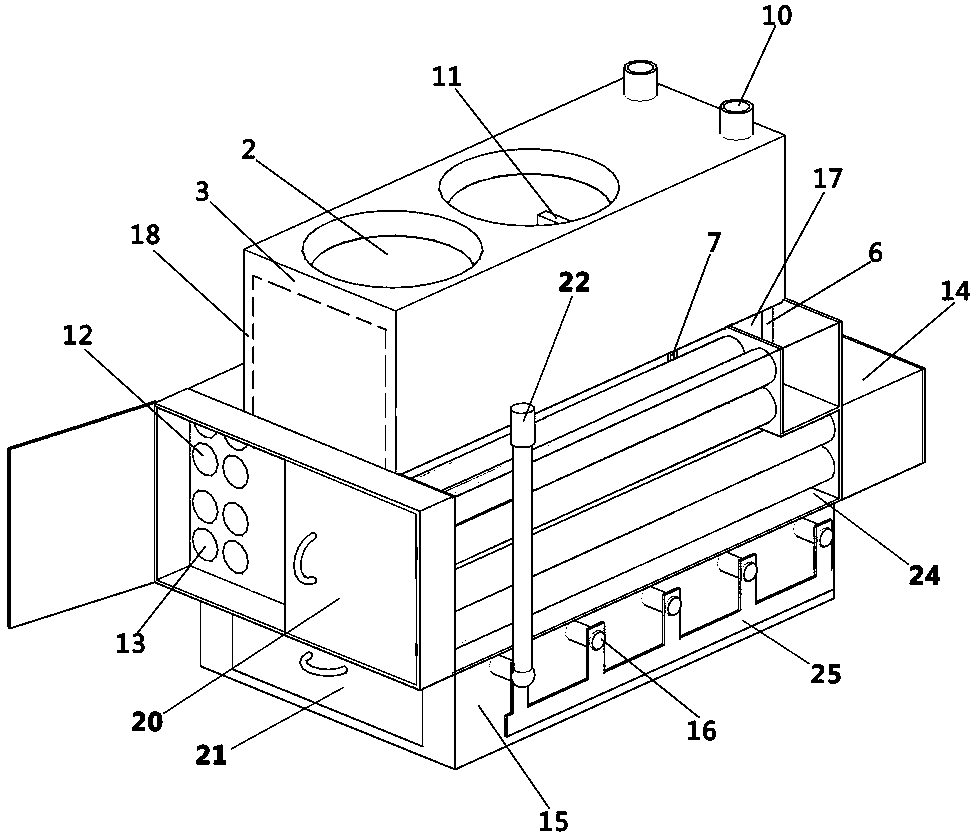

[0031] like figure 1 , figure 2 As shown, the furnace body of the heating furnace of the present invention is a rectangular horizontal furnace body, a furnace 1 is arranged in the furnace body, a grate 16 and an ash storage chamber 15 are arranged at the bottom of the furnace hearth 1, and ash storage chamber 15 is housed in the ash storage chamber 15. Bucket 21, fire grate 16 also can be worn and connected on the support 25, and is controlled with rocking handle 22, to carry out rotation cleaning. A furnace water jacket is arranged on the periphery of the furnace 1, and the furnace water jacket is surrounded by interconnected furnace front wall water jacket layers 4, furnace side wall water jacket layers 18 and furnace rear wall water jacket layers 6. The top layer of the furnace is also provided with a furnace top water jacket layer 3, and the furnace top water jacket layer 3 communicates with the furnace front wall water jacket layer 4, the furnace side wall water jacket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com