An automatic wax removal device for oil wells

An automatic wax removal technology, which is applied in the direction of isolation devices, cleaning tools, boreholes/well parts, etc., can solve the problems of not being able to remove wax quickly and efficiently, and achieve the goals of controlling the running time of the equipment, simplifying the equipment, and improving the life of the equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

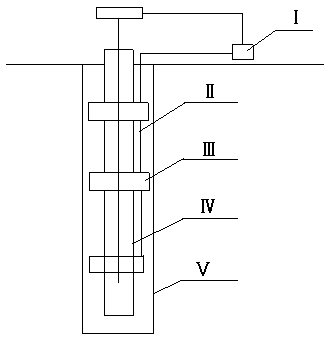

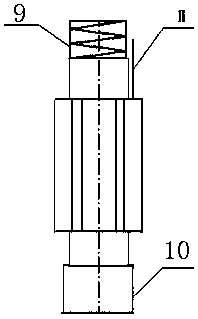

[0021] In order to overcome the problem that the existing devices cannot remove wax quickly and efficiently, the present invention provides an automatic wax removal device for oil wells. The present invention adopts the principle of shielding of microwaves by metals and penetrability of microwaves to organic materials, and according to the type of heating fluid Different, different types of magnetrons are used to directly heat the fluid, which can quickly heat the oil well output fluid. When heating the produced fluid, different types of magnetrons can efficiently heat the produced water and crude oil, and use the upward process of the produced fluid to heat the waxed tubing section. The heated water vapor and associated gas are heated, and the density of the heated water vapor and associated gas becomes smaller, which will form a convective heat exchange with the upper low-temperature gas, which can quickly heat up, compensate for the heat dissipation of the oil pipe, maintain...

Embodiment 2

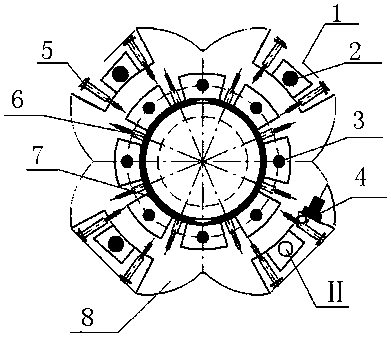

[0031] On the basis of Embodiment 1, in this embodiment, the wax removal unit body 8 is connected to a lotus-shaped platform by four semicircles connected end to end, and the three external magnetrons 2 and one armored The cables II are respectively located at the four semicircular protrusions of the lotus-shaped wax removing unit body 8 .

[0032] Adopt the semicircle material that connects end to end, reduce the weight of wax removal unit body 8 like this, save material, under the situation that guarantees normal operation, save cost, lighten the weight of whole device.

[0033] The outer magnetron 2 and the armored cable II are provided with trapezoidal organic material seals 1 , and the trapezoidal organic material seals 1 are fixed on the wax removal unit body 8 by external fastening bolts 5 .

[0034] An annular organic material seal 7 is arranged in the through hole of the wax removal unit body 8 , and the annular organic material seal 7 and the wax removal unit body 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com